Key Takeaways:

- Surface roughness, surface texture, surface finish, surface roughness measurement, profilometer, Ra value, Rq roughness, and high-precision optics are essential for controlling optical performance.

- Nanometer-scale roughness causes light scattering, distortion, and lowers laser damage thresholds.

- Surface roughness results from manufacturing methods, material structure, and environmental effects.

- Tools like profilometers and AFM provide accurate surface measurement and analysis.

- Avantier ensures ultra-smooth optics with advanced polishing, metrology, and cleanroom control.

Introduction

In high‑precision optics, surface roughness is the defining measure of microscopic imperfections that directly influence light propagation. Using advanced surface roughness measurement techniques—backed by profilometers and optimized polishing—ensures optimal surface finish and overall system performance. This focus on surface texture is what separates good from exceptional optical quality.

What Is Surface Roughness?

Surface roughness refers to tiny, fine-scale surface irregularities. It is distinct from larger form deviations like waviness or flatness and typically involves spatial wavelengths under 100 μm. These minute height variations—though nearly invisible—have significant impacts on how light interacts with the surface, especially in sensitive optical systems.

Surface texture is a broader term that includes surface roughness, lay, and waviness. While roughness reflects the small, closely spaced irregularities, texture captures the overall topographic characteristics of a surface.

Key Roughness Parameters

- Ra value (Arithmetic Average Roughness): The most widely used surface roughness parameter. It represents the arithmetic mean of the absolute distances between the surface profile and the mean line over a sampling length. A low Ra indicates a smoother surface, essential for reducing optical scattering.

- Rq roughness (Root Mean Square Roughness): This is the square root of the average of the squared profile deviations. Rq provides more weight to larger deviations than Ra, making it more sensitive to outlier features. It’s especially important in optics where even minor peaks can scatter light and affect performance.

- Rz (Maximum Height of Profile): Measures the average vertical distance from the five highest peaks to the five deepest valleys within a sampling length. It’s useful for assessing potential for mechanical interference or laser damage at surface high points.

- PSD (Power Spectral Density): PSD analysis shows how roughness is distributed across spatial frequencies, allowing prediction of light scattering behavior over various wavelengths. It is particularly helpful in laser optics and systems sensitive to angular scattering.

Why Surface Roughness Matters in Optics

Even nanometer-level surface roughness can cause significant issues in precision optics:

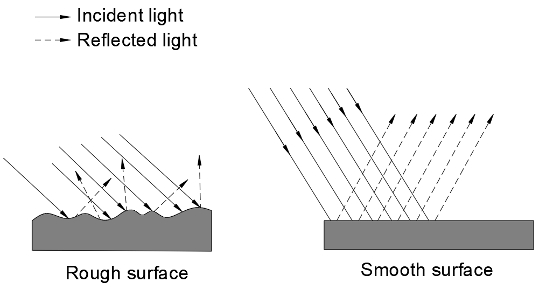

- Light Scattering: Micro-scale surface features cause diffuse reflection, scattering light in unintended directions. This reduces image contrast in cameras, telescopes, and microscopes and can introduce noise in sensor systems.

- Wavefront Distortion: Uneven surfaces alter the phase of transmitted or reflected light, leading to degraded resolution and focus in high-performance systems like interferometers and lithography tools.

- Laser Energy Loss & Beam Quality: Rough surfaces can absorb and scatter laser light, causing efficiency loss and creating hotspots. This affects laser cutting, surgery, and communication applications.

- Lower Damage Threshold (LIDT): Tiny surface spikes amplify local electric fields under intense light, causing premature material breakdown. Minimizing roughness raises durability in high-energy laser systems.

- Reduced Efficiency in Diffractive Elements: Holograms, gratings, and waveguides require well-controlled microstructure. Surface roughness disrupts the intended diffraction patterns, reducing device effectiveness.

- Poor Surface Finish Compounds the Problem: A poorly finished surface increases the chances of contamination, coating defects, and reflection losses. Controlling finish is critical in multi-layer coated optics and assemblies.

Common Causes of Surface Roughness

- Manufacturing Process

- Grinding & Polishing: During mechanical finishing, abrasive grains remove material but can leave micro-scratches and pits, especially if abrasive size distribution or pressure is inconsistent. Sub-surface damage may also result if not properly controlled.

- Single-Point Diamond Turning (SPDT): Offers nanometer-level surface generation but is affected by tool edge wear, thermal drift, and machine vibration. Improper cutting parameters can leave periodic tool marks or chatter.

- Precision Molding & Injection Molding: In replicated optics (e.g., plastic lenses), mold quality directly determines surface texture. Worn or contaminated molds transfer defects onto every produced piece.

- Etching (Chemical/Ion): Surface texture depends on etch uniformity. Uneven etching from plasma or wet chemistry processes can introduce unpredictable micro-roughness.

- Material Constraints

- Polycrystalline Substrates: Grains and grain boundaries respond differently to mechanical stress, leading to differential material removal.

- Inclusions & Bubbles: Internal voids or impurities within glass or crystal can emerge at the surface during polishing, creating pits or voids.

- Amorphous Materials: Even though structurally uniform, atomic disorder in materials like optical glass imposes an intrinsic roughness floor.

- Post-Processing & Environmental Factors

- Contamination During Cleaning: Use of improper solvents or wipes can scratch or leave residues that degrade surface quality.

- Film Coating Process: Physical vapor deposition (PVD) and sputtering techniques may produce non-uniform films if process parameters fluctuate, increasing roughness.

- Environmental Exposure: Airborne particles, moisture, and chemical vapors can cause corrosion or embed debris into polished surfaces, increasing roughness over time.

Techniques for Measuring Surface Roughness

- Profilometers

- Contact Profilometers: Use a stylus to physically trace the surface topography. These tools are durable and suitable for many industrial surfaces. They provide absolute height data and are ideal for Ra, Rq, and Rz analysis, though they may scratch sensitive optics.

- Non-Contact Optical Profilometers: Use white-light or laser interferometry to create high-resolution 2D or 3D maps. They are ideal for delicate, coated, or transparent surfaces. Fast scanning and sub-nanometer vertical resolution make them invaluable in optical metrology.

- Atomic Force Microscopy (AFM)

- Offers the highest spatial resolution among surface roughness measurement tools. By detecting nanoscale force interactions between a sharp tip and the surface, AFM produces topographic maps down to the atomic level. It’s best suited for ultra-smooth surfaces such as EUV optics or laser mirror coatings.

- Together, these tools ensure a comprehensive assessment of surface roughness and are integral to precision manufacturing workflows.

Avantier’s Approach to Surface Roughness Control

Advanced Surface Metrology

Avantier employs the NewView 9000 3D Optical Surface Profiler for detailed, non-contact surface characterization. It allows us to:

- Accurately measure Ra, Rq, Rz, and full surface profiles

- Detect and map micro-defects across large surface areas

- Compare surfaces before and after polishing, coating, or cleaning

- Ensure consistency and traceability for customer QA records

Ultra-Precision Finishing

- Magnetorheological Finishing (MRF): Utilizes magnetic fields to shape polishing fluids that conform to surface curvature. Enables deterministic removal of roughness down to <0.5 nm Rq, without edge roll-off or sub-surface damage.

- Ion Beam Polishing (IBF): Uses a collimated ion beam to physically sputter away high spots. Offers atomically smooth finishes ideal for deep-UV and x-ray optics.

Diamond Turning & Freeform Machining

- Our diamond turning systems achieve Ra < 2 nm on metals and IR crystals using nanometer-position control, hydrostatic bearings, and vibration-isolated platforms. This process is crucial for producing infrared lenses and reflective elements.

Cleanroom & Contamination Control

- All critical polishing, metrology, and coating operations are performed in Class 10–100 cleanrooms.

- We use ultrasonic and megasonic cleaning processes with multi-stage DI rinses to ensure zero contamination that could affect surface finish or lead to increased scattering.

Conclusion

Surface roughness is a critical parameter in the manufacture and performance of high-precision optics. It influences everything from light transmission and reflection to system durability and laser threshold. Through advanced surface roughness measurement, optimized finishing techniques, and rigorous contamination control, Avantier delivers components that meet the most demanding industry specifications.

When precision counts, trust Avantier to deliver optics with the perfect surface texture, engineered for performance at every level.

GREAT ARTICLE!

Share this article to gain insights from your connections!