Key Takeaways

- Satellite telescope coatings must support wide spectral ranges (UV to LWIR) while enduring radiation, AO exposure, and thermal cycles.

- AR coatings for lenses and windows require high transmittance, environmental resistance, and minimal outgassing.

- Gold and silver reflective coatings are essential for high-efficiency IR mirrors in thermal imaging telescopes.

- AO-resistant layers like ALD-deposited Al₂O₃ or DLC are critical for LEO survivability.

Selecting the Right Coatings for Space: From UV to LWIR

Optimizing AR coatings, gold/silver mirrors, and atomic oxygen resistance for satellite telescopes

Satellite telescopes operate in one of the harshest environments in optical engineering—exposed to radiation, atomic oxygen, extreme thermal cycles, and broad spectral demands. From imaging Earth in the visible and near-infrared to observing celestial bodies in UV or thermal infrared, these instruments require coatings that ensure long-term performance, stability, and survivability.

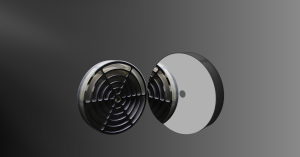

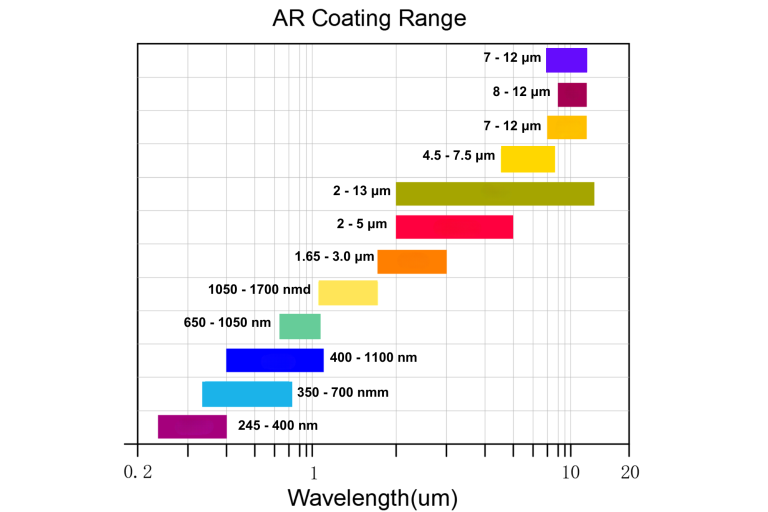

1. Anti-Reflective (AR) Coatings for Multi-Band Performance

Maximizing optical throughput and minimizing ghosting in satellite telescopes requires high-performance AR coatings tailored to specific mission wavelengths. Whether for Earth observation, star tracking, or atmospheric analysis, broadband AR coatings are essential.- Deep UV to NIR Telescopes: Dielectric multilayers using materials like MgF₂, LaF₃, and Al₂O₃ are engineered for high transmittance and low absorption in vacuum conditions.

- Multispectral Imaging Systems: Custom AR coatings may be applied to complex optics, such as lenses in wide-field imagers or corrector plates in Ritchey–Chrétien configurations.

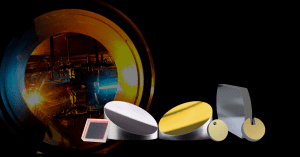

2. Gold and Silver Coatings for IR Optics

For satellite telescopes operating in MWIR and LWIR, particularly in thermal imaging or space surveillance missions, metallic coatings become indispensable.- Gold (Au): Delivers high reflectivity from 0.7 µm to 20 µm and excellent vacuum stability. Commonly used on mirrors in passive infrared telescopes or thermal detectors.

- Silver (Ag): Preferred for its high visible/NIR reflectivity but must be protected by dielectric overcoats to prevent degradation.

3. Resistance to Atomic Oxygen (AO) in LEO

In Low Earth Orbit (LEO), satellite telescope optics must withstand erosion caused by atomic oxygen—an aggressive species that degrades exposed coatings and polymers.- Protective Layers: ALD-deposited Al₂O₃ or DLC (diamond-like carbon) can serve as effective AO barriers without compromising optical performance.

- Substrate Compatibility: Coatings must also be mechanically compatible with telescope materials (e.g., SiC mirrors or optical polymers) under AO and thermal stress.

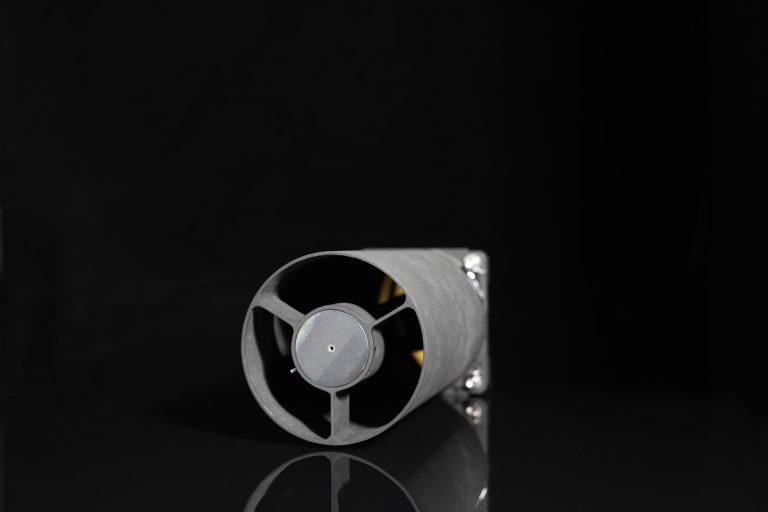

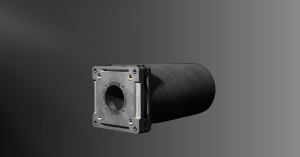

4. System-Level Design for Satellite Telescopes

Advanced satellite telescopes often integrate multiple optical paths or fold mirrors—each requiring specific coatings to meet both spectral and thermal requirements.

- Dual-Band Systems: Telescopes combining visible and IR paths need hybrid coating stacks—e.g., an IR-reflective gold surface with a visible-pass AR overlay.

- Thermal Management: Coatings with controlled absorptance/emittance help manage stray light and thermal equilibrium, reducing image distortion and sensor noise.

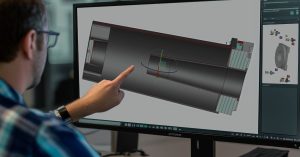

Partner with Us for Space-Ready Optics

At Avantier, we understand the complex challenges of designing optical systems for space. Whether you need flight-ready optical coatings, precision optical design support, or fully customized lens and mirror assemblies, our team is equipped to deliver high-performance solutions from UV through LWIR. We collaborate closely with engineers and researchers to meet mission-specific requirements—whether for satellite telescopes, star trackers, or multi-spectral payloads. Our in-house capabilities allow for flexibility, fast turnaround, and innovation at every stage. Contact us today to discuss your optical needs for space and beyond.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!