Key Takeaways:

- Overconfidence in idealized models can lead to disappointing real-world results in optical systems. While these models provide valuable insights, they assume perfect conditions that don’t exist in practice.

- Aberrations, distortions, and the diffraction limit are unavoidable factors that impact system performance. To ensure your designs meet real-world expectations, account for these deviations early on.

Overconfidence in Idealized Optical Models

Idealized models are a wonderful way to get a quick grasp of how an optical system might work. But be careful! Real life will never meet your ideal model.

Overconfidence in idealized optical models is a common pitfall, especially for those relatively new in optics. The ideal world our theories are based on is imaginary. Real rays of light have real widths. A real plane wave extends to infinity in all directions. Real lenses aren’t perfect optical elements that are free of aberration and focus light to a single point. And there’s no such thing as a perfect point source.

There’s nothing wrong with making estimations to make it possible to do your calculations— but it’s important to realize what those estimations are and be aware of the confidence intervals in which your figures work.

This article is the third part of a six-part series to “Avoid Optical Pitfalls” in the industry. Each article will look at a topic that is often confused, and provide a brief, easy-to-understand explanation of the key foundational concepts involved.

Overconfidence in Idealized Optical Models: Ideal Lens & Aberrations

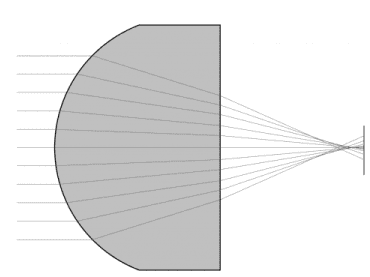

An ideal lens is a perfectly formed flat uniform lens in which the laws of refraction work perfectly. Parallel rays of light hitting the surface of the lens would be transmitted through the lens and all be focused at a single point on the other side— the focal point. Each point on the object focuses to a point on the image— a mathematical point of zero size.

In the real world, we can make lenses that are pretty well perfectly formed. But no matter how perfect we make them, they’ll never be able to do exactly what an ideal lens does. That’s because an idealized model assumes many things that are not exactly true in real life. And the point on the object will never actually map onto a point of zero size.

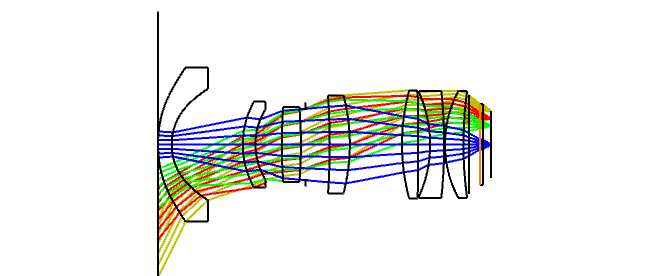

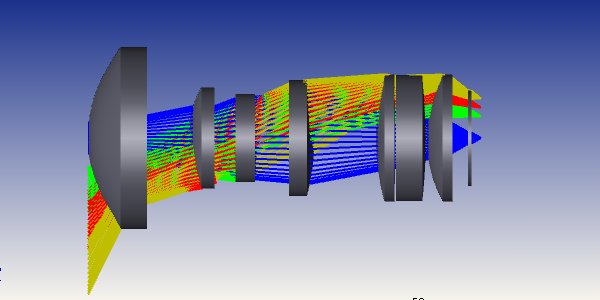

There are several important types of aberrations that describe how light moves through a lens in a way that differs from ideal. Aberration might be a confusing word here, as we’re not talking about unexpected, unpredictable problems that come up randomly. In optics, aberrations are the calculable and expected deviation from a theoretical ideal that we get from our simplified models. They include spherical aberrations, coma aberrations, chromatic aberrations, field curvature, and astigmatism.

Distortions are special types of aberration. In distortion, information is displaced; so while the image is changed it is not blurred. Since the distance each ray of light is distorted at any point can be mathematically quantified, this type of aberration is easy to correct in post-processing. Radial distortion, barrel distortion, perspective distortion, and pincushion distortion are all types of distortions.

Realistic Expectations for Optical Models

How can you avoid this optical pitfall and get a realistic view of how your optical system is likely to work? If you’ve got a custom at Avantier in the pipeline, talk to your optical design and engineering team about just what aberrations and other deviations from an ideal, theoretical situation mean to your application. If you’re working with high precision optics, another key concept you will need to consider is how resolution is constrained by the diffraction limit, a result of the wave nature of light which cannot be overcome, no matter how high quality your optics might be.

At Avantier, we pride ourselves on producing the highest quality optics available anywhere. We can work with you to design and produce an optimal solution to whatever optical problem you might have. A wide range of high quality manufacturing equipment and state of the art metrology equipment allows us to produce, polish, and measure every piece to ensure it meets the highest standards.

If you use idealized optical models and don’t factor in the way real optics— and real light— behave in the real world, you may still end up disappointed. So do the math ahead of time. Find out what the diffraction limit is for your system. Find out what aberrations you can expect, and if that is more than you can deal with in your application, our design team can help you create a system that uses different components to cancel out aberrations and distortions and make the best image possible.

We’re on your team— and we want your optics to work the way you expect them to, in the real world.

GREAT ARTICLE!

Share this article to gain insights from your connections!