Key Takeaways:

- Hot and cold mirrors are dielectric-coated optics that selectively reflect or transmit infrared (IR) radiation, offering valuable heat management solutions.

- Hot mirrors reflect up to 90% of near-IR (NIR) and IR light while transmitting UV and visible light. Conversely, cold mirrors reflect UV and visible light, transmitting up to 80% of NIR and IR.

- These versatile optics can be tailored for various applications, such as beamsplitters or filters, and are essential in systems where thermal control is critical, including automotive displays.

- Avantier provides custom solutions for diverse industries.

Hot Mirrors and Cold Mirrors

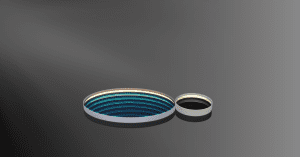

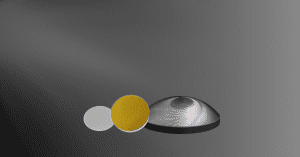

If you need to protect a delicate experimental setup from unwanted heat, you may need a hot mirror or a cold mirror. Hot mirrors and cold mirrors are versatile optics designed to separate infrared radiation from other light. They are typically multilayer dielectric mirrors, and can be manufactured in a variety of different substrates and configurations.

In this article we’ll look at hot mirrors and cold mirrors and just how they accomplish their purpose. Before we finish, we’ll go through a comparison of their technical features that can help you decide which mirror is best for you.

Hot Mirrors

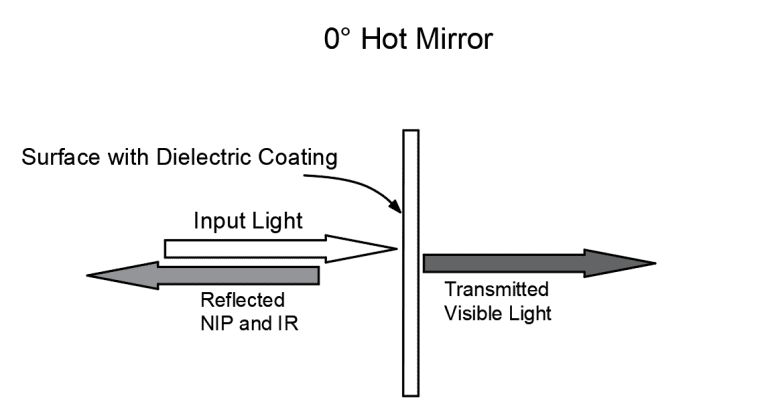

Hot mirrors reflect as much as 90% of NIR and IR light while transmitting up to 80% of UV and visible light. Depending on the experimental setup, the reflected heat may be directed toward a heat sink or alternative component that can make use of the energy, or simply away from any delicate components that should be protected from heat.

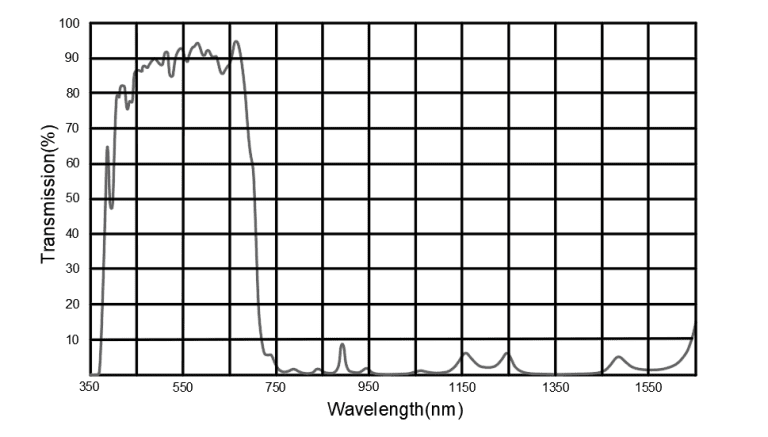

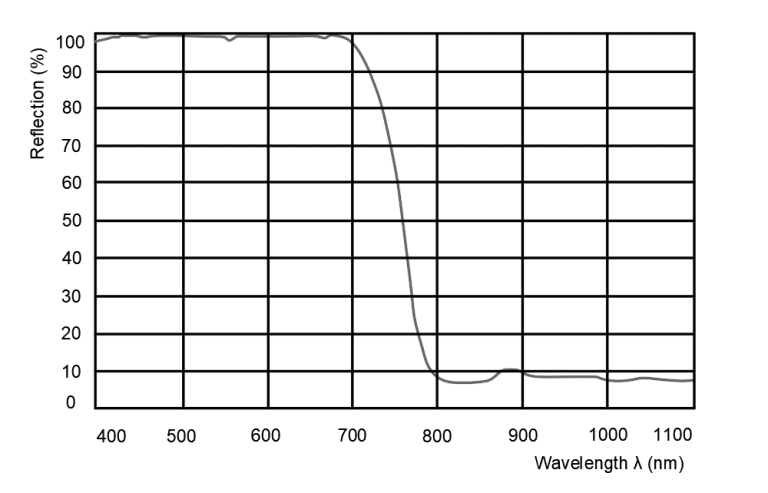

Hot mirrors can also be used as bandpass filters or beamsplitters. The image below shows a typical transmission curve for a hot mirror.

A custom hot mirror can be designed to perform best at any specific angle of incidence between 0° and 45°. Typically, either a 0° or 45° angle of incidence is chosen.

Cold Mirrors

Cold mirrors do the same job as hot mirrors do— separating UV and visible light from NIR and IR—- but they do it the opposite way. Instead of reflecting IR light and transmitting visible, they reflect 90% of UV and visible light while transmitting as much as 80% of NIR and IR light. Because of this, a reflectance curve for a cold mirror looks very similar to a transmittance curve for a hot mirror— you just need to remember you’re looking at two different features. Compare the image below with the transmission curve of the hot mirror above.

An incident angle of 0° and 45°— or any angle in between- can be chosen when a cold mirror is designed. It’s also possible to design a cold mirror that transmits UV light and only reflects the visible spectrum.

Just like hot mirrors, cold mirrors can be used as beamsplitters or bandpass filters, with a laser beam, for instance. You can even use hot and cold mirrors together, set up in conjunction, to pass visible light and block UV, IR, and NIR.

One modern use of cold mirrors is the heads up display in an automobile. Cold mirrors are used to project the visible image to the viewer, while transmitting NIR and IR away from the system to eliminate heat buildup and image distortion.

Comparison of Hot Mirrors and Cold Mirrors

Hot and cold mirrors are very similar in many ways, including their applications. Both are dichroic filters; mirrors manufactured with carefully customized dielectric coatings on glass substrates. Both can be manufactured to any desired angle of incidence, from 0 to 45. And both can be used to separate IR and NIR light from visible and UV wavelengths.

Deciding whether you want to go with a hot mirror or cold mirror often comes down to decisions about the preferred beam path in your optical system. Would you rather set up a mirror so that the unwanted light is reflected out of your system, or would you rather it was transmitted away?

There’s one more important technical difference between the two types of mirrors. While a hot mirror reflects 90% of NIR and IR light while transmitting up to 80% of visible, a cold mirror transmits up to 80% of IR or near IR light while reflecting up to 90% of the visible spectrum. If you need to isolate a full 90% of NIR and IR light, you will need to work with a hot mirror. Similarly, if 80% of visible light transmittance is not enough for your application, you’ll need to use a cold mirror.

Hot Mirrors and Cold Mirrors at Avantier

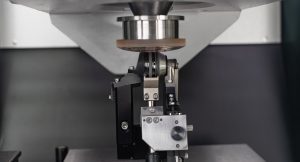

At Avantier we produce custom hot and cold mirrors for customers in research, industry, medicine and defense. Our team of optical engineers and designers are available to work with you on your optical application, and state of the art manufacturing equipment allows us to produce almost any component in-house. Throughout the optics world, we’re known for going the extra mile to ensure our clients are fully satisfied. Contact us today to get started with your own design project or custom order.

GREAT ARTICLE!

Share this article to gain insights from your connections!