Key Takeaways

- ISO 10110 is the global standard for representing optical components in technical drawings, ensuring clear communication between designers and manufacturers.

- It defines specifications for surface form, material quality, surface texture, coatings, tolerances, and alignment—critical for precision lens design.

- By standardizing symbols and notations, it minimizes errors, improves quality, and supports international collaboration.

- Adhering to ISO 10110 enhances performance, reduces costly rework, and ensures lenses meet strict requirements, making it essential for producing reliable, high-quality optical systems across industries.

Optical Drawing Standards for Lens Design

Optical design demands precision and unambiguous communication. To ensure consistency and accuracy throughout the design and manufacturing process, the ISO 10110 standard provides a universal system for representing optical components. This guide introduces the core elements of ISO 10110, empowering designers and manufacturers to interpret and apply these standards for superior optical performance and quality.

What is ISO 10110?

ISO 10110 is an international standard for representing optical components in technical drawings. This system is widely used in industries involved with optical engineering and manufacturing. It ensures that everyone involved in the production, from designers to manufacturers, understands the specifications clearly and consistently. The standardization provided by ISO 10110 helps streamline the communication process, reducing the risk of misinterpretation that can lead to costly errors or rework.

The implementation of ISO 10110 extends beyond the drawing board, impacting every stage of the optical component lifecycle. From initial design through to final production, ISO 10110 serves as a vital reference point, ensuring that all stakeholders are aligned on the design specifications. By adhering to this standard, companies can enhance their reputation for quality and reliability, as well as improve their competitive edge in the global marketplace.

Why Use ISO 10110?

Using ISO 10110 helps avoid misunderstandings by providing a clear and standardized way to represent optical specifications. This is particularly important when working with complex lens systems where precision is crucial. Consistency in drawings reduces errors and helps ensure that the final product meets the required specifications. By using ISO 10110, organizations can minimize the risk of costly production errors and enhance their ability to deliver high-quality optical products.

Moreover, ISO 10110 fosters international collaboration by providing a common language that transcends geographical boundaries. This standard is recognized and utilized worldwide, making it easier for multinational teams to work together seamlessly. It also facilitates smoother transactions and negotiations, as all parties involved have a mutual understanding of the specifications and quality standards being discussed.

Key Components of ISO 10110 Optical Drawings

Surface Form

The surface form of a lens is indicated in the ISO 10110 drawings to describe any deviation from the ideal surface shape. This is crucial because even minor deviations can significantly affect the performance of an optical system. Precise control over surface form ensures that lenses focus light accurately, maintaining the integrity of the optical design and ensuring that the final image quality is not compromised. In ISO 10110 drawings, specific symbols and notations are used to convey information about surface form. These notations help engineers and manufacturers understand the allowable deviations from the intended design, enabling them to produce lenses that meet stringent performance criteria. By specifying surface form in detail, ISO 10110 helps mitigate the risk of lens aberrations and other optical distortions that could impair functionality.Material Quality

Material quality is another critical factor represented in ISO 10110 drawings. ISO 10110-2 specifically addresses imperfections such as bubbles, inclusions, and striae in optical materials. Defining acceptable levels of these imperfections helps ensure the optical homogeneity and clarity necessary for high-performance lenses. ISO 10110 provides a framework for specifying material quality, including aspects such as refractive index, dispersion, and thermal properties. By clearly defining these parameters, ISO 10110 helps manufacturers select the appropriate materials that will meet the performance demands of specific optical applications. This attention to detail in material selection is crucial for the development of lenses that perform reliably under various environmental conditions.Surface Texture

Surface texture refers to the microscopic features of the lens surface, such as roughness and waviness. These features can influence the scattering of light and, consequently, the image quality. A well-controlled surface texture minimizes unwanted scattering and ensures that light is transmitted or reflected as intended, enhancing the clarity and sharpness of the final image.

While ISO 10110 does not assign a specific part solely to surface roughness, such characteristics are often included in ISO 10110-8 (Surface texture). This ensures that scattering and stray light are minimized through controlled surface quality.

Incorporating surface texture specifications into ISO 10110 drawings allows manufacturers to achieve the desired optical characteristics. By providing explicit guidelines for surface texture, ISO 10110 helps reduce variations in production, ensuring that each lens meets the required performance standards. This attention to surface texture also plays a critical role in minimizing optical noise and other artifacts that could degrade image quality.

Coating Specifications

Lens coatings are essential for enhancing the performance of optical systems. These are defined in ISO 10110-5, which outlines how to specify coatings in terms of type, function, and durability. Properly defined coating specifications help reduce reflections, increase transmission, and protect optical surfaces in demanding environments.

Different coatings serve various purposes, such as anti-reflective coatings to minimize glare or protective coatings to extend the lifespan of the lens. ISO 10110 ensures that these coatings are applied consistently and according to precise specifications, helping to achieve optimal performance across different lighting conditions and environments. By standardizing coating specifications, ISO 10110 facilitates the production of lenses that meet stringent quality requirements.

ISO 10110 Part | Specification Area | Description |

Part 1 | General principles | Layout and interpretation rules for optical drawings |

Part 2 | Material imperfections | Inclusions, bubbles, and striae in optical glass |

Part 5 | Coatings | Functional and protective coating specifications |

Part 8 | Surface texture | Surface roughness and microroughness |

Part 14 | Surface imperfections (Scratch-Dig) | Quantifying scratches, digs, and defects |

Understanding the key elements in lens design in ISO 10110

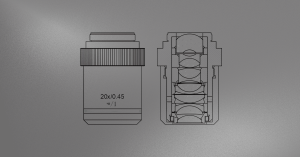

Numerical Aperture and Focal Length

The numerical aperture and focal length are critical parameters in lens design. ISO 10110 drawings provide a clear representation of these values, ensuring that the lens meets the desired optical performance. These parameters influence the lens’s ability to gather light and resolve fine details, making them fundamental to the design process. Accurate depiction of numerical aperture and focal length in ISO 10110 drawings ensures that lenses are manufactured to meet specific performance criteria. This precision is essential for applications requiring high-resolution imaging or precise focus, such as in microscopy or photography. By adhering to ISO 10110 standards, designers can be confident that their lenses will deliver the expected performance in real-world scenarios.Tolerances

Tolerances indicate the acceptable limits of variation in the lens’s dimensions and optical properties. ISO 10110 specifies these tolerances clearly, which is vital for maintaining the precision of optical systems. Tolerances define the range within which a lens can deviate from its intended design while still functioning correctly. By specifying tolerances in ISO 10110 drawings, manufacturers can ensure that lenses are produced with the required accuracy, minimizing the risk of defects or performance issues. Tight tolerances are especially important in high-performance optical systems where even minor deviations can lead to significant degradation in performance. ISO 10110 provides a framework for defining these tolerances, enabling the production of lenses that meet the highest standards of quality and precision.Aspheric Surfaces

Aspheric surfaces are used in advanced optical systems to reduce aberrations. ISO 10110 drawings include detailed specifications for aspheric surfaces, ensuring that they are manufactured to precise standards. Aspheric lenses offer superior optical performance by minimizing distortions that are common in spherical lenses, such as spherical aberration. The inclusion of aspheric surface specifications in ISO 10110 drawings allows designers to leverage these advanced optical elements effectively. By providing clear guidelines for the production of aspheric surfaces, ISO 10110 helps ensure that these lenses deliver the enhanced performance benefits they are designed for. This precision is crucial for applications requiring high-quality imaging, such as in telescopes or high-end cameras.Centering and Alignment

Proper centering and alignment of optical components are crucial for optimal performance. ISO 10110 provides guidelines for these parameters, ensuring that each component is correctly positioned within the optical system. Misalignment can lead to a range of issues, including image distortion and reduced optical efficiency. By adhering to ISO 10110’s centering and alignment guidelines, manufacturers can produce optical systems that perform reliably and consistently. These guidelines help ensure that lenses and other components are assembled with the precision necessary to achieve the desired optical performance. This attention to detail is essential for maintaining the integrity of the optical design and ensuring that the system functions as intended.How to Read ISO 10110 Optical Drawings

Reading ISO 10110 drawings requires familiarity with the symbols and notations used in the standard. Here are some tips to help you interpret these drawings effectively:

- Familiarize Yourself with Symbols: ISO 10110 uses a set of standardized symbols to represent different optical properties. Understanding these symbols is essential for interpreting the drawings correctly. This knowledge will enable you to quickly grasp the specifications and requirements outlined in the drawings, facilitating smoother communication and collaboration with your team.

- Focus on Key Specifications: Pay attention to critical specifications such as surface form, material quality, and coating details. These elements have a significant impact on the lens’s performance. By concentrating on these key areas, you can ensure that your optical components meet the necessary standards and deliver the expected results in their applications.

- Check Tolerances: Ensure that the tolerances specified in the drawing meet the required precision for your application. Tight tolerances are often necessary for high-performance optical systems. Verifying these tolerances will help you identify any potential discrepancies early in the process, reducing the risk of costly rework or adjustments.

- Verify Coating Details: Coatings are vital for enhancing lens performance. Make sure that the coating specifications in the drawing align with your needs. Confirming these details ensures that the lenses will function optimally under the intended conditions, maximizing their efficiency and lifespan.

Conclusion

ISO 10110 optical drawings are an essential tool for engineers and designers working with lens systems. They provide a standardized way to represent the complex specifications of optical components, ensuring consistency and precision in manufacturing. By understanding the key elements in lens design in ISO 10110, you can improve the accuracy and efficiency of your optical projects. Whether you’re designing a new lens or manufacturing optical components, mastering ISO 10110 is crucial for success in the field of optical engineering.

By integrating these practices into your workflow, you can enhance the quality and performance of your optical systems, ultimately delivering better results for your projects and clients. Embracing ISO 10110 not only streamlines your design and manufacturing processes but also positions you as a leader in the optical engineering industry, capable of producing innovative and reliable optical solutions that meet the highest standards of excellence.

GREAT ARTICLE!

Share this article to gain insights from your connections!