Key Takeaways

- Optical domes, also known as dome windows, are high-precision optical components used in imaging systems. They provide high quality and transmission through precision manufacturing and anti-reflection coatings, ensuring performance in high-pressure environments.

- Made from durable materials like sapphire and BK7 glass, they protect cameras, lenses, and sensors while offering a wider field of view compared to flat ports.

- Applications include underwater cameras, aerospace, defense, scientific research, and surveillance.

- Key design considerations include material selection, curvature, coatings, and environmental resistance. Proper mounting and sealing are essential to maintain optical integrity and prevent contamination.

Optical Domes: Applications and Design Considerations

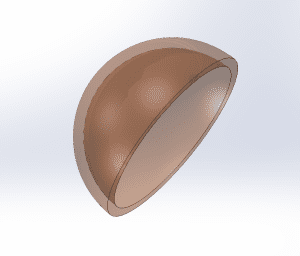

An optical dome, also known as a dome window, is a specialized type of protection window used in various optical detection and imaging systems. They are high-precision optical components used in various dome applications, offering high quality and high transmission through the use of precision optical manufacturing techniques and anti-reflection coatings. These domes ensure optimal performance and reliability even in high pressure environments.

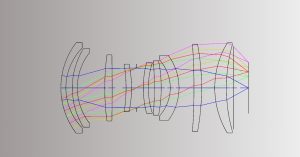

An optical dome consists of two dome-shape surfaces and allows light rays to pass through with minimal effect on the optical performance of the optical instruments. They are usually made from durable materials (such as sapphire, Fused Silica, tempered BK7 glass ) to protect /cover the camera, lenses, sensors, etc.

Dome-shaped optical components typically offer a wider field of view compared to flat ports. These domes are commonly used in various applications such as underwater cameras (withstanding high pressure in the deep sea), aircraft navigation systems, surveillance systems, scientific instruments, etc. They play a vital role in protecting optical systems while ensuring optimal performance in various applications that require transparent enclosures.

Applications

- Wide-view cameras / detectors: Optical domes provide protection for the camera lens or detector housing, shielding them from scratches, abrasions, and other potential damage. Compared to traditional flat windows, dome windows with curved surfaces are designed to reduce surface reflections and improve optical efficiency, especially at wide angles of incidence.

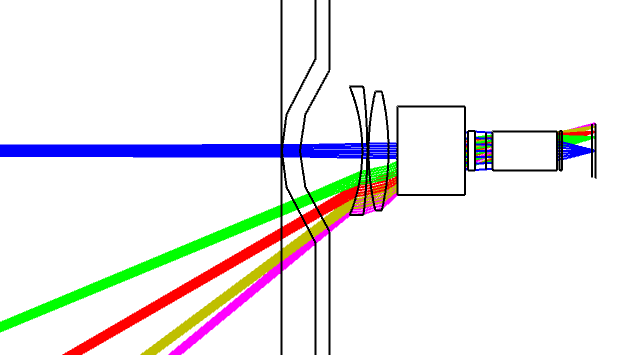

- Underwater imaging cameras: When light passes from water to air, it undergoes refraction, causing optical distortion and aberration in images captured underwater. Dome windows are designed to mitigate these effects by providing a curved surface that helps to reduce the effect of the abrupt change in refractive index between water and air, minimizing distortion and maintaining image clarity.

- Aerospace and Defense: Optical dome windows are utilized in aircraft, drones, and missiles for surveillance, reconnaissance, and targeting systems. They provide protection for sensors and cameras while ensuring clear optical performance.

- Scientific Research: Dome windows are used in various scientific instruments and observatories, including telescopes, spectrographs, and environmental monitoring systems.

- Surveillance and Security: Security cameras and surveillance systems may employ dome windows to protect lenses and sensors from vandalism, weather, and other environmental factors.

Design Considerations for Optical Domes

The design is crucial for maintaining image clarity and minimizing optical distortion caused by refraction or reflection. They are typically made from materials with high optical clarity and strength.

Key considerations in the design include:

- Material selection: Choosing a material with the appropriate optical properties (refractive index, dispersion, etc.) and mechanical properties (strength, durability, etc.) is essential for achieving optimal performance.

- Curvature: The curvature of the dome affects its optical characteristics, such as field of view, distortion, and image sharpness. Careful design considerations are necessary to balance these factors based on the specific application requirements.

- Coatings: Anti-reflective coatings can be applied to optical domes to minimize reflection losses and improve optical transmission.

- Environmental factors: Optical domes often operate in challenging environments, such as underwater or in aerospace applications. Design considerations must include factors such as pressure resistance, temperature stability, and resistance to scratching or abrasion.

- Mounting and sealing: Proper mounting and sealing techniques are crucial to maintain the integrity of the optical system enclosed within the dome and to prevent contamination or damage.

Custom Optical Domes

GREAT ARTICLE!

Share this article to gain insights from your connections!