Key Takeaways

- Projects in aerospace, biomedical imaging, and other high-precision sectors often hinge on expert optical engineering.

- Warning signs you need this expertise include: when optical performance is mission-critical, prototypes rely on trial-and-error, off-the-shelf optics fail specs, integration issues degrade performance, or timelines can’t support in-house hires.

- Skilled optical engineers apply advanced modeling, custom design, and environmental hardening to ensure precision, reliability, and efficiency.

- Partnering early reduces risk, accelerates schedules, and delivers systems that meet or exceed performance goals within budget.

In advanced product development, optical subsystems often determine the success or failure of the final system.

In sectors such as spaceborne instrumentation, biomedical imaging, precision manufacturing, and autonomous sensing, performance margins are narrow and error tolerance is minimal.

When optical design and integration are not handled by qualified engineers, small design oversights can result in substantial schedule delays, increased costs, and compromised performance.

The following five indicators suggest that your project requires dedicated optical engineering support.

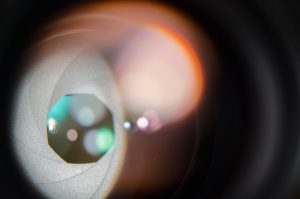

1. Optical performance defines mission success

In high-stakes environments — such as earth observation satellites, laser communication payloads, fluorescence microscopy systems, or optical coherence tomography (OCT) — system performance depends on precise control of light.

Meeting these requirements demands expertise in aberration correction, light distribution uniformity, stray light suppression, and optical tolerancing.

Without this, space systems risk degraded resolution due to thermal distortion in orbit, and biomedical systems risk compromised diagnostic accuracy due to poor image fidelity.

2. Prototyping relies on iterative trial-and-error

In both spacecraft payload development and medical device prototyping, empirical iteration without predictive modeling is inefficient and risky.

An optical engineer can apply ray tracing, wavefront error budgeting, spectral optimization, and Monte Carlo tolerancing to virtually validate designs — mitigating chromatic aberration, field curvature, or diffraction effects before costly components are fabricated.

3. Off-the-shelf optics cannot meet specification

When catalog components fail to satisfy requirements — such as maintaining uniform illumination in an endoscopic probe, achieving high MTF in a satellite imaging telescope, or meeting stringent weight limits for a CubeSat payload — custom optical solutions are necessary.

This can involve aspheric lens design, lightweight mirror substrates, high-efficiency diffractive optical elements, or specialized coatings to withstand vacuum UV exposure in space.

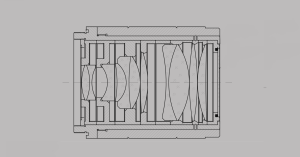

4. System integration challenges are eroding performance

Optics operate within a broader electromechanical and thermal environment.

In space systems, this means accounting for launch vibration, microgravity-induced alignment shifts, and extreme thermal gradients.

In biomedical devices, it can mean integrating miniature optics into handheld instruments without sacrificing resolution or light throughput.

An optical engineer ensures optical tolerances are aligned with mechanical stability, thermal expansion, and environmental robustness.

5. Project timelines cannot accommodate the hiring of in-house specialists

In industries with aggressive schedules — such as satellite constellations racing for launch windows or biomedical device firms meeting regulatory approval deadlines — waiting months to recruit a full-time optical engineer is impractical.

An external optical engineering partner brings ready-to-deploy design tools, calibration procedures, and test protocols to begin work immediately, ensuring optical performance development keeps pace with system-level progress.

Conclusion

In high-performance sectors such as aerospace and biomedical engineering, the absence of specialized optical expertise introduces avoidable technical and commercial risk.

Engaging an experienced optical engineering partner enables:

- Accurate modeling of light paths and image formation

- Optimized aberration correction for mission-specific conditions

- Robust light distribution for measurement precision

- Environmentally hardened designs for demanding operational contexts

The result: systems that meet or exceed performance targets, delivered on schedule and within budget.

Contact us to discuss how our optical engineering services can support your next mission or device.

GREAT ARTICLE!

Share this article to gain insights from your connections!