Key Takeaways

- The Silicon Carbide Mirror for Aerospace combines a lightweight design, thermal stability, and high reflectance for optimal performance in extreme conditions.

- With precise dimensions (±0.1 mm) and exceptional surface accuracy (RMSI < 16 nm), it delivers clear, distortion-free imaging for satellite and deep-space applications.

- Its durable protective coating (>95% reflectance) withstands harsh environments.

- Proven in a space mission, the mirror enhanced imaging accuracy, reduced mission weight by 15%, and demonstrated exceptional reliability over two years of operation.

Project Overview

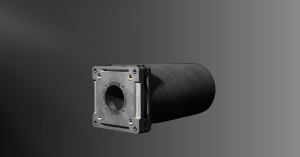

The Silicon Carbide Mirror was specifically designed to meet the stringent requirements of aerospace engineering, ensuring exceptional performance in challenging conditions. Its lightweight structure, combined with superior optical properties, makes it a critical component in space exploration and satellite imaging systems.

Key Challenges Addressed

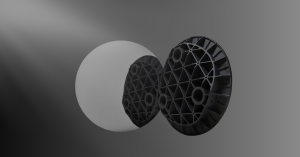

- Thermal Stability: Aerospace environments demand materials with low thermal expansion. Silicon carbide’s excellent thermal conductivity and minimal expansion make it ideal for high-temperature and vacuum conditions.

- Precision Optics: The tight dimensional tolerance (±0.1 mm) and outstanding surface accuracy (RMSI < 16 nm) ensure optimal imaging performance, even for demanding space missions.

- Durability in Harsh Environments: The protective silver coating provides high reflectivity (>95%) across a broad wavelength range (400-12,000 nm), while also shielding the mirror from corrosion and mechanical damage in extreme conditions.

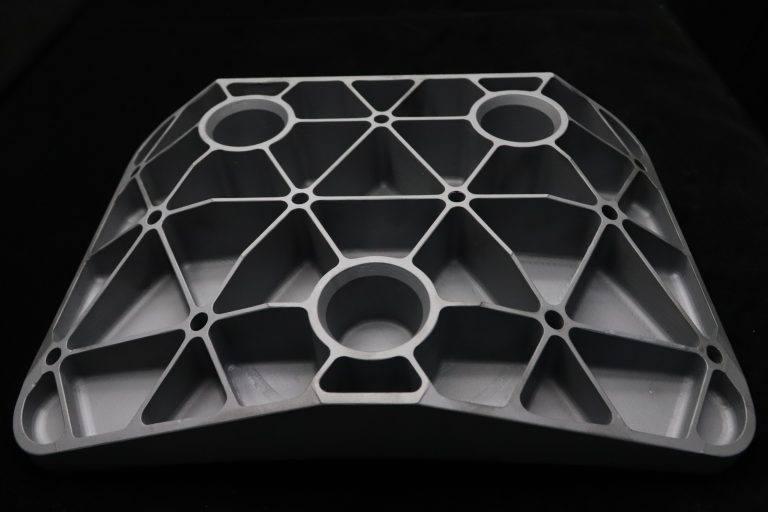

Innovative Design Features

- Compact Dimensions: At 379 mm x 260 mm x 85 mm, the mirror balances size and performance, making it suitable for tight payload constraints.

- High Reflectance Coating: The mirror’s coating optimizes performance for wavelengths critical in infrared and visible spectroscopy used in aerospace applications.

- Advanced Material Composition: Silicon carbide combines lightweight characteristics with robust mechanical strength, enhancing reliability during launch and operation in orbit.

Product Specifications

Material | Silicon Carbide |

Dimensions | Length: 379 mm, Width: 260 mm, Thickness: 85 mm |

Dimension Tolerance | ±0.1 mm |

Clear Aperture | 90% |

Surface Quality | 80-50 |

Surface Accuracy | RMSI < 16 nm |

Coating | Protective Ag |

Reflectance (Rabs) | >95% @ 400-12,000 nm |

Angle of Incidence (AOI) | 0 – 4.5° |

Application Highlights

- Satellite Imaging: The mirror’s high surface quality (80-50) and accuracy ensure clear, distortion-free images essential for earth observation and mapping.

- Astronomical Observations: Its precision and high reflectivity are key for capturing faint celestial objects in deep-space telescopes.

- Lidar and Laser Systems: The mirror’s consistent performance at various angles of incidence (0-4.5°) makes it valuable for space-based Lidar systems.

Performance Metrics

A recent deployment in a space mission demonstrated the mirror’s capabilities:

- Achieved clear imagery with minimal distortion during a temperature fluctuation range of -50°C to +60°C.

- Maintained reflectance above 95% over a two-year observation period.

- Successfully integrated into the payload, reducing overall mission weight by 15% compared to conventional mirrors.

Customer Impact

By utilizing the Silicon Carbide Mirror, the aerospace client has achieved:

- Enhanced imaging accuracy, contributing to critical data collection for climate research.

- Cost-efficiency in mission planning due to the material’s longevity and reduced maintenance needs.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!