Key Takeaways

- Large optical prisms play a crucial role in scientific research, requiring a manufacturing process that is highly precise to ensure their quality and performance.

- This project enhances optical communication by using BK7 material with special coatings and red, green, and blue lasers from different directions.

- Manufacturing challenges include complex processes, stringent material selection, surface quality control, and maintaining optical performance consistency, with automation and digital technologies improving production accuracy.

- Avantier’s precision lenses enable success in scientific, military, and consumer applications by providing superior-quality images and precise positional information, earning customer trust and satisfaction with exceptional design and quality.

Large Optical Prisms: Applications and Challenges

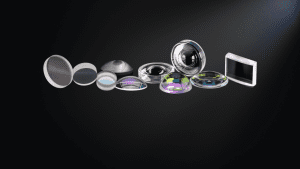

A large optical prism is an optical component with extensive applications across various industries. These optical prisms play a crucial role in different sectors, from scientific research, Medical Imaging, Communication Technology, and Laser Processing and Manufacturing, due to their unique design and performance. Manufacturing large optical prisms poses several challenges due to the unique characteristics and requirements associated with their size and optical properties. This article explores the primary application areas of large optical prisms and their pivotal role within these fields.

Project Overview

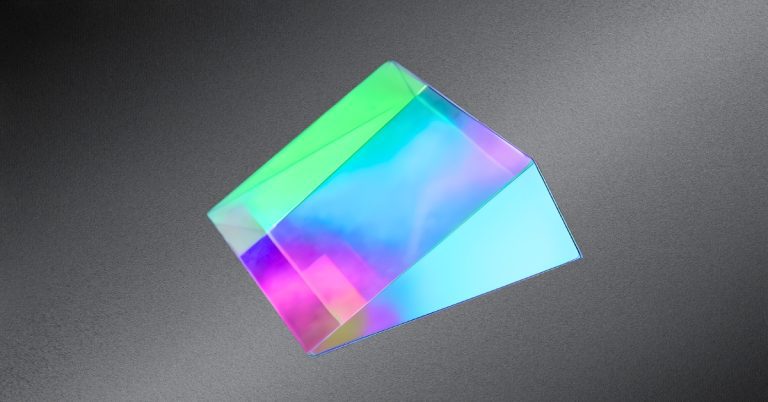

This project is used for entertainment & research, applied in the field of communication, utilizing a unique design that employs red, green, and blue lasers from three different directions that pass through the optical prisms, ultimately forming images in three distinct directions. These optical prisms are used for modulating and demodulating light signals, and they aid in achieving high-speed and stable optical communication. The use of optical communication systems is continuously increasing, and the application of large optical prisms enhances the efficiency and reliability of these systems. To ensure the final imaging quality, our company has chosen the material BK7 and has implemented a special coating.

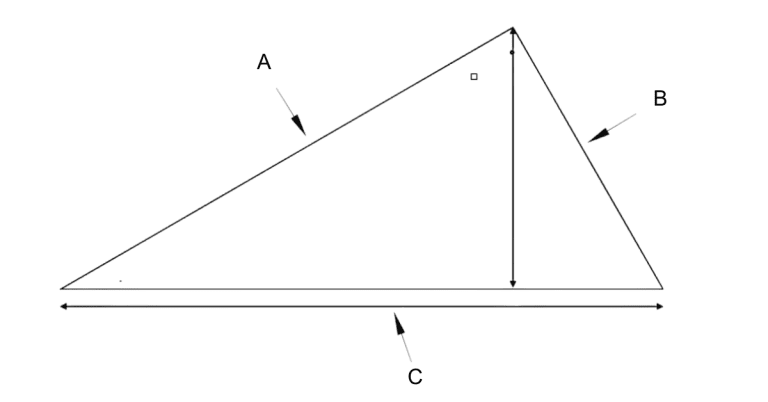

As shown in the diagram, (A, B, and C) represents three different colors of lasers (R,B, and G) passing through the optical prism from three distinct directions.

Manufacturing

In the manufacturing process of large optical prisms, there are various challenges and issues, and some of the main problems include:

- Complexity of Manufacturing Processes: Producing large optical prisms requires more complex manufacturing processes. From material selection to shaping, highly precise processes are needed to ensure their quality and performance. This involves control, calibration, and meticulous monitoring of each manufacturing step.

- Material Selection: Finding suitable materials for them is a critical issue. Material properties such as thermal stability, optical transparency, and manufacturability need to be considered comprehensively. In the case of large-sized optical prisms, the performance of materials significantly affects the quality and stability of the final product.

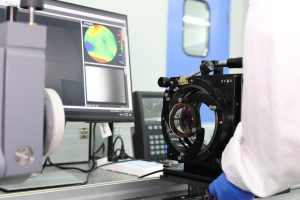

- Surface Quality Control: The surface quality of large-sized optical prisms is crucial for their performance in optical systems. Strict control over surface smoothness and shape errors is necessary during the manufacturing process to ensure the precision and clarity of the final product. This may involve highly precise polishing and coating techniques.

- Consistency of Optical Performance: Ensuring the consistency of optical performance is a challenge in the production of large-sized optical prisms. This includes maintaining consistency in refractive index, dispersion characteristics, and optical distortions in order to meet the requirements of different applications. This may require precision measurement and testing equipment, as well as real-time monitoring and adjustments during the manufacturing process.

- Automation and Digitized Production: Applying automation and digital technologies can enhance the consistency of the production process. Usage of automated equipment and advanced control systems can reduce human errors and ensure that each prism’s manufacturing process is similar.

Conclusion

The large optical prism is a versatile optical component extensively used in scientific research, medical imaging, communication technology, and laser processing. Employing a unique design with red, green, and blue lasers, it enhances optical communication efficiency. The project, focused on entertainment and research, utilizes BK7 material with special coating for optimal imaging quality. However, large-sized optical prism manufacturing poses challenges, including complex processes, material selection, surface quality control, and ensuring optical consistency. Precision manufacturing, stringent quality control, consistent material selection, and automation play crucial roles in overcoming these challenges and ensuring the their high-quality performance.

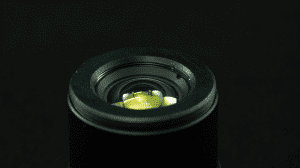

Avantier’s ability to provide lenses with this kind of performance allows customers in scientific research, military, and consumer applications to acquire high-quality images and use accurate positional information, thereby achieving success in many applications. Customers trust this product and are satisfied with our superior design capabilities and high-quality products.

Avantier’s capacity to deliver lenses exhibiting such remarkable performance empowers customers in scientific research, military, consumer applications to capture superior-quality images and obtain highly precise positional information, leading to success in diverse fields. Our customers place confidence in this product, expressing satisfaction with our exceptional design capabilities and the superior quality of our products.

GREAT ARTICLE!

Share this article to gain insights from your connections!