Key Takeaways

- Optical metrology equipment facilitates non-contact, precise measurements crucial for ensuring quality and accuracy in various applications.

- This non-contact technology allows for precise measurements of object characteristics without the need for physical contact, providing invaluable data for research, development, and quality control purposes.

- Its ability to provide high-precision measurements swiftly contributes to efficient processes and reliable results.

The Significance of Optical Metrology: Precision and Versatility

Optical metrology, often underestimated, is a powerful and versatile tool that uses light to measure the characteristics of an object, leading to applications in various fields. This article delves into how optical metrology works, its numerous applications, and the advantages and disadvantages of this remarkable technology.

Understanding Optical Metrology

Optical metrology operates by harnessing the properties of light to interact with the object under scrutiny and then analyzing the reflected, refracted, transmitted, or absorbed light to obtain crucial measurements. The techniques employed in optical metrology include interferometry, speckle pattern analysis, and the projection of laser structured light patterns. These techniques allow for the measurement of properties such as distance, shape, and surface roughness.

- Interferometry: This method utilizes multiple beams of light to create interference patterns, enabling precise distance measurements between the object and the measuring device.

- Speckle Pattern Analysis: This technique examines the way light scatters on a rough surface to determine its roughness, contributing to more accurate surface quality assessments.

- Structured Light Patterns: By projecting laser lines or patterns onto the object, a 3D map of the object’s shape can be created based on how the pattern or laser line is deflected.

Applications of Optical Metrology

The versatility of optical metrology is evident in its diverse applications:

- Optical Profilometers: These instruments offer high-resolution surface topography measurements, surpassing the capabilities of traditional microscopes.

- Spectrographs and Wave Meters: These tools provide precise measurements of spectral optical properties, crucial in various scientific and industrial settings.

- Fiber-Optic Temperature and Strain Sensors: Used in monitoring temperature and strain in critical infrastructure like oil, gas, and power lines.

- Optical Clocks: These advanced tools provide incredibly precise measurements of optical frequencies, outperforming even atomic clocks.

- Optical Temperature Sensors: They utilize thermal emission to optically measure the temperature of high-temperature objects.

- Optical Time-Domain Reflectometers: These devices inspect fiber optics and locate faults in splices or connections.

- Optical Coordinate Measuring Machines (CMMS): These employ optical triangulation methods to scan objects in 3D, providing accurate coordinate measurements.

- Time of Flight Sensors: They use real-time laser pulse measurements to swiftly gauge distances and depths, even at considerable distances.

Advantages and Disadvantages of Optical Metrology

Optical metrology offers a range of advantages:

- Non-Contact Measurement: No physical contact with the object being measured minimizes the risk of damage.

- High Precision: Optical methods provide highly precise measurements, ideal for applications demanding precision.

- Speed: Optical metrology delivers rapid measurements, making it invaluable for time-sensitive applications.However, it’s important to be aware of the disadvantages:

- Environmental Sensitivity: Changes in temperature, humidity, and vibration can affect accuracy, making it challenging in certain conditions.

- Limited Range: The effectiveness of optical metrology depends on the specific method used, potentially limiting its ability to measure large objects or surfaces.

- Cost: The equipment and technology required for optical metrology can be expensive, potentially restricting accessibility for some applications or industries.

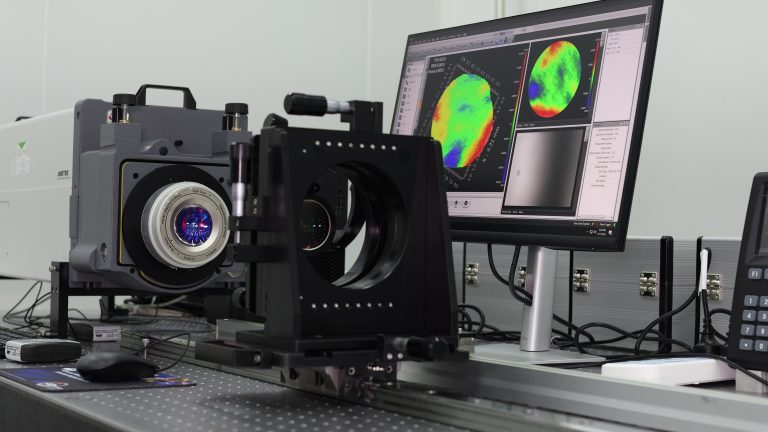

Advanced Optical Metrology Testing at Avantier

At Avantier, we employ our state-of-the-art metrology equipment to thoroughly test every component and assembly before it leaves our factory. Our advanced tools include the Zygo Verifire Interferometer, which provides precise readings of surface accuracy, surface form, and the transmitted wavefront of optical components and assemblies. Additionally, our Trioptics MTF test stations enable comprehensive infrared wavelength MTF measurements, both off-axis and on-axis, for high-precision lenses.

Our precision metrology equipment assesses various parameters, including Field Curvature, Astigmatism, Distortion, Relative FFL/BFL, Effective Focal Length, Through Focus MTF, Line Spread Function, and Phase Transfer Function, ensuring the highest quality and accuracy in our products.

In conclusion, optical metrology is a remarkable and versatile technology with a broad range of applications, despite its few limitations. Its precision, non-contact nature, and speed make it a valuable asset in numerous industries, and its ability to provide critical data for quality control, research, and development is undeniable. As technology advances, optical metrology continues to play an essential role in various fields, offering unparalleled accuracy and reliability.

GREAT ARTICLE!

Share this article to gain insights from your connections!