Key Takeaways

- Reliable Delivery: Avantier supplied high-precision infrared objective lenses on time, safeguarding the customer’s production schedule.

- Quality Assurance: Enhanced coating processes eliminated adhesion and color issues, ensuring both technical performance and visual consistency.

- Full Traceability: Each lens was supported with design documentation, approval records, and laser-engraved IDs for complete product confidence.

- Customer Confidence: By aligning testing with the actual operating spectral range, Avantier ensured validation reflected real-world conditions, strengthening long-term trust and partnership.

Project Background

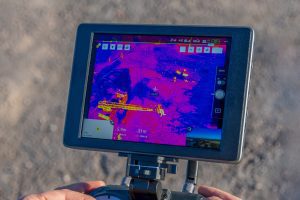

Avantier partnered with a leading scientific instrumentation company to design, produce, and supply High-Precision Infrared Objective Lenses. These custom optical components were integrated into advanced analytical instruments, which are widely used in laboratories, research institutions, and industrial quality-control environments.

The project demanded not only optical excellence but also close technical collaboration to ensure the lens design, acceptance criteria, and supporting documentation aligned precisely with the customer’s operational and compliance needs.

Customer Challenges

The customer faced several critical pain points:

- Quality Concerns: Previous suppliers had delivered defective or non-compliant lenses, raising doubts about consistency and reliability.

- Testing Uncertainty: Initial tests did not fully reflect their actual instrument’s spectral range, making validation less meaningful.

- Tight Production Timelines: Any delay in lens delivery risked disrupting their own production schedule, potentially impacting their customers downstream.

Customer Requirements

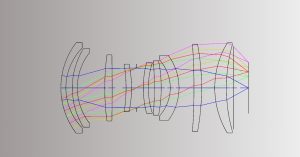

To meet their instrument design needs, the customer specified highly demanding requirements:- Optical Specifications:

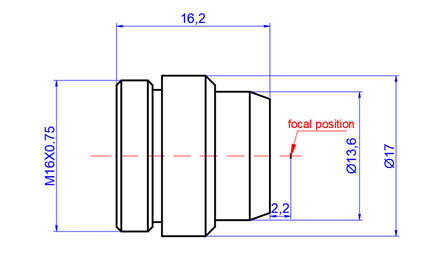

- Effective focal length: ~6.73 mm at 8 µm

- F-number: 0.67

- Lens length: ~18.45 mm

- Wavelength coverage: 5.5–11.25 µm

- Field of view: ~3°

- Performance Standards:

- MTF > 0.5 at 40 lp/mm at 8 µm

- MTF > 0.55 at 25 lp/mm at 12 µm

- Validation Needs:

- Testing within the true operating range of 5.5–10.3 µm

- Comprehensive documentation including design drawings, acceptance records, and traceability to prior approvals

Avantier’s Approach

Avantier worked closely with the customer to build confidence and deliver a solution tailored to their needs:- Aligned Testing: All validation was performed within the instrument’s actual spectral range, ensuring that results directly reflected real-world conditions.

- Full Documentation: We provided complete design drawings, acceptance documentation, and approval records to establish transparency and traceability.

- Agile Delivery: To address urgent timelines, we arranged partial shipments ahead of schedule while continuing production, minimizing any disruption to the customer’s operations.

Technical Challenges & Solutions

1. Membrane Detachment

The Challenge: The infrared film coating initially experienced adhesion issues, with peeling detected during testing. Root Causes Explored:- Incomplete cleaning of the substrate

- Impurities such as oil or dust

- Uneven edge temperature during coating

- Excessive internal stress in the film layer

2. Lens Color Variations

The Challenge: The wide operational wavelength range (5–11.5 µm) required specific coatings. However, these coatings influenced the visible light range (400–700 nm), leading to color variations across batches. While performance remained consistent, the customer was dissatisfied with inconsistent visual appearance. Solution: Avantier redesigned the membrane system and enhanced the multilayer coating process. This ensured both optimal infrared performance and controlled color uniformity in the visible range, delivering High-Precision Infrared Objective Lenses that met both technical and aesthetic expectations.

Ensuring Traceability

To provide robust after-sales support, each lens was laser-engraved with a unique identity code, allowing precise tracking of product history and performance throughout its lifecycle.

Results & Customer Impact

- Reliable Performance: Delivered lenses that fully met stringent optical and performance requirements.

- Customer Confidence: Transparent documentation and testing alignment eliminated concerns over compliance.

- Operational Continuity: Agile delivery schedules prevented disruptions to the customer’s instrument production line.

- Enhanced Quality Control: Improved coating processes ensured both functional excellence and visual consistency.

Delivering Precision and Customer Confidence

Through a combination of technical expertise, rigorous process improvements, and customer-focused collaboration, Avantier successfully delivered High-Precision Infrared Objective Lenses. This project not only met the customer’s demanding specifications but also reinforced their trust in Avantier as a long-term optical partner.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!