Key Takeaways:

- This case study highlights distortion correction with F-theta lenses in laser processing, ensuring uniform spot size and shape.

- Essential for precision tasks in electronics, medical devices, and high-precision tools, these lenses enhance efficiency and reduce costs by accurately focusing on curved surfaces.

- With key specifications like moderate magnification, broad wavelength range, and minimal distortion, F-theta lenses offer versatility and high accuracy, making them ideal for diverse industrial applications.

Case Study: Distortion Correction with F-theta Lens

In the realm of laser processing and optical engineering, furthermore, F-theta 3D conjugate lenses are designed to correct inherent distortions that occur during the conjugate process, ensuring uniform spot size and shape across the entire scan field. This precision is crucial in applications requiring meticulous attention to detail, such as the manufacturing of intricate electronic components, medical devices, and high-precision tools. Moreover, by leveraging advanced optical designs and high-quality materials, these lenses enhance the performance of laser systems, enabling them to meet the demands of modern industrial and technological applications.

The integration of F-theta 3D conjugate lenses into optical systems brings significant improvements in efficiency and productivity. With the ability to accurately focus the laser beam on curved and irregular surfaces, these lenses facilitate faster processing speeds and higher throughput, reducing operational costs and increasing overall output. Additionally, their adaptability across various wavelengths makes them suitable for a wide range of materials, from metals and plastics to ceramics and composites.

F-Theta Lens Specification

Focal Length |

5mm |

F Number |

5.6 |

Wavelength |

400 – 700nm. |

Image height |

3.2mm |

Object height |

10mm |

Working distance |

100mm |

Back focal length |

18mm |

Lens size |

Φ9×L20mm |

Distortion |

<0.1% |

Lens Design Overview

The F-Theta 3D conjugate lens is a meticulously designed component, ensuring optimal performance for high-precision laser applications. It features key specifications that highlight its capabilities and suitability

for a wide range of industrial and technological uses. These specifications, combined with insights from broader industry applications, underscore the lens’s advantages.

- Moderate Magnification: Ideal for detailed work while maintaining a manageable working distance and suitable for laser marking, engraving, and micromachining.

- Balanced Light-Gathering and Depth of Field: Ensures sufficient light reaches the target, enhancing image clarity and sharpness.

- Broad Wavelength Range: Covers the visible spectrum, allowing use with various lasers and flexibility for processing different materials (metals, plastics, ceramics, composites).

- High Precision for Small Areas: Projects clear and detailed images over small areas, perfect for applications like microfabrication and high-resolution engraving.

- Versatility in Object Size: Suitable for small to moderately sized objects and ideal for detailed inspection and processing tasks.

- Working Distance: Facilitates easy handling and enhances safety by preventing damage from close contact.

- Optimal System Integration: Ensures proper alignment within optical systems, maintaining system integrity and achieving precise results.

- Compact Size: Allows for easy integration into various systems. It is also suitable for portable and handheld devices and beneficial for tight spaces.

- Low Distortion (Distortion Correction): Ensures scanned images remain true to their original shapes, which is crucial for precision applications such as aerospace engineering.

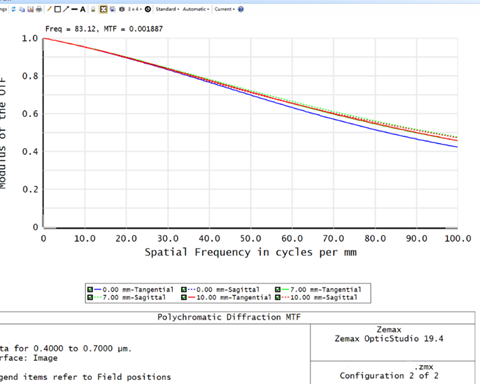

Modulation Transfer Function

The MTF plot measures the lens’s ability to transfer contrast at different spatial frequencies from the object to the image. Moreover, this plot, generated using Zemax OpticStudio 19.4, shows that the lens maintains high contrast transfer efficiency, with an MTF value of 0.8189 at a spatial frequency of 83.46 cycles per mm. The analysis covers various field positions (0.00 mm, 7.00 mm, and 10.00 mm) for both tangential and sagittal components, indicating the lens performs well across the field with slight variations.

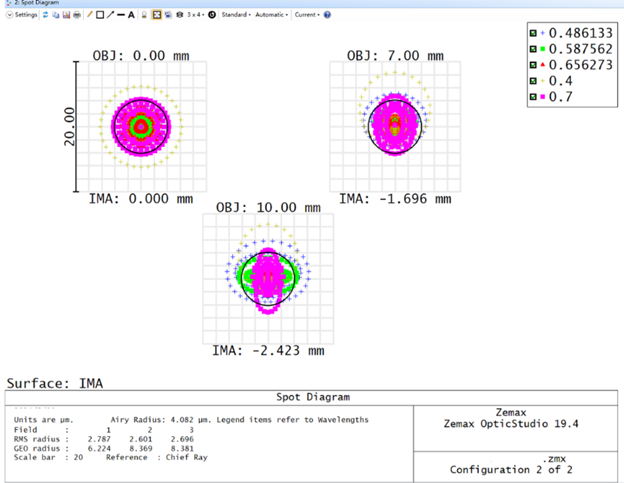

Spot Diagrams

Spot diagrams offer a visual representation of how light from different field positions is focused on the image plane. Furthermore, this indicates spot distributions for object positions at 0.00 mm, 7.00 mm, and 10.00 mm. The closeness of the spots to the Airy disk, with an Airy radius of 4.095 μm, demonstrates the lens’s precision in focusing light. The RMS and geometric radii values for the spot sizes (3.701 μm and 9.712 μm, respectively, for the central field) show minimal deviation, suggesting high optical quality.

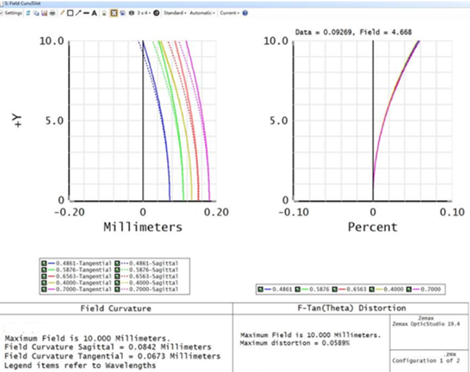

Field curvature plots

Field curvature plots illustrate the deviation of the image plane from a flat surface across different wavelengths. Additionally, this plot indicates that the lens exhibits slight sagittal and tangential curvatures, with maximum field curvatures of 0.0842 mm (sagittal) and -0.0673 mm (tangential) for a maximum field height of 10 mm. These values reflect the lens’s ability to maintain focus across the field with minimal curvature-induced aberrations.

F-Theta Lens Advantages

- Versatility and Flexibility: The F-Theta 3D conjugate lens’s ability to operate across a wide range of wavelengths and its compact design make it highly versatile. Consequently, it can be used in various industries, from manufacturing and medical fields to scientific research, accommodating different lasers and materials.

- High Precision and Accuracy: The low distortion rate and high image clarity ensure that even the smallest details are accurately captured and processed. Moreover, this precision is crucial for applications requiring meticulous attention to detail, such as semiconductor manufacturing and high-precision engraving.

- Ease of Integration: The compact size and standard specifications, such as the back focal length, make the lens easy to integrate into existing optical systems. In addition, this ease of integration reduces downtime and enhances productivity in industrial applications.

- Enhanced Safety and Usability: The ample working distance and robust design ensure that the lens can be used safely and effectively in various environments. This feature is particularly important in automated systems and environments where safety is a priority.

The Indispensable Role of Wide-Angle Lenses

To conclude, this F-theta 3D conjugate lens from Avantier showcases exceptional performance in high-precision laser applications. Notably, its versatility, high precision with distortion correction, ease of integration, and enhanced safety make it an invaluable component for various industrial and technological uses. Avantier’s advanced optical design and high-quality materials ensure that their F-theta lenses meet the demands of modern industrial applications, significantly improving efficiency and productivity.

GREAT ARTICLE!

Share this article to gain insights from your connections!