Key Takeaways

- Powell lens transforms Gaussian beams into straight, uniform lines by fanning out collimated beams, eliminating central hot spots for even light distribution.

- This project focuses on custom-manufactured Powell lenses with specific fan angles and incident spot sizes, exemplified by a 30° fan angle lens designed for a 2.5mm input beam diameter and visible light wavelengths.

- These lenses are crucial for applications in laser communication, medical devices, and precision measurements, ensuring optimal performance through tailored designs.

Powell Lenses

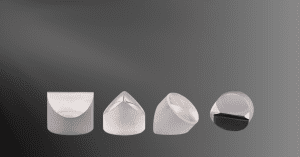

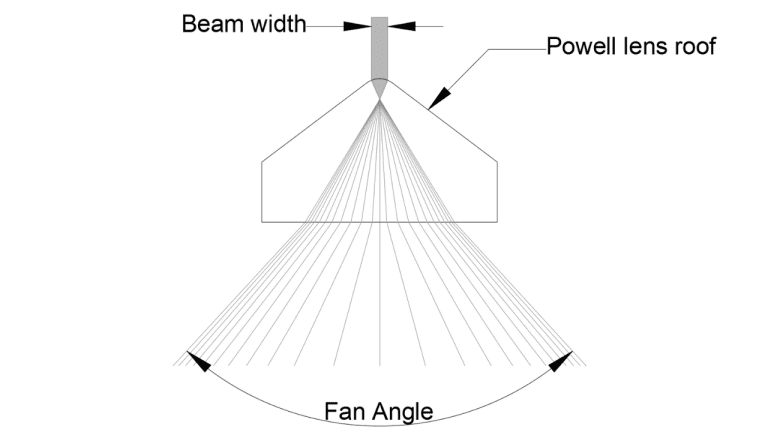

Powell lenses are laser line generator lenses that fan out collimated beams in one dimension. Shaped like a prism with a rounded roof, they transform a narrow laser beam into a uniformly illuminated line. Unlike cylindrical lenses, which create lines with fading edges and a central hot spot, Powell lenses produce straight lines with even energy and light distribution.

Project Overview

This project involves a custom-manufactured Powell lens with specifications based on the customer’s request. It focuses on two main indicators that affect the design of Powell prisms: the fan angle and the incident spot size.

Indicators of Powell Prism

Two main indicators affect the design of the Powell prism: the fan angle and the incident spot size.

The fan angle refers to the angle of the light beam when it passes through the Powell lens and opens into a fan. It is obvious that the larger the fan angle, the longer the length of the linear beam obtained at the same distance.

The size of the incident light spot is another important indicator that affects the design of the Powell lens. For a laser with a Gaussian distribution, the incident spot size refers to the spot diameter when the energy drops to a peak of 1/e². In general, specific Powell prisms are only suitable for incident beams of the corresponding size. If the size of the beam is not matched, the energy distribution of the outgoing beam will be significantly affected.

30° Fan Angle Powell lens

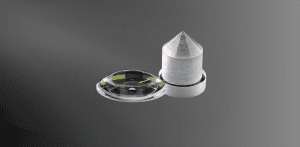

The following is a 30° fan angle Powell lens, designed for the incident spot size of 2.5mm, suitable for visible light wavelength.

Fan Angle | 30° |

Input Beam Diameter | 2.5mm |

Wavelength | 400-700nm |

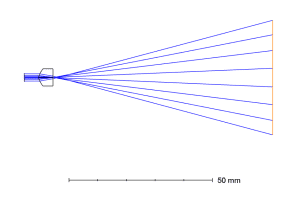

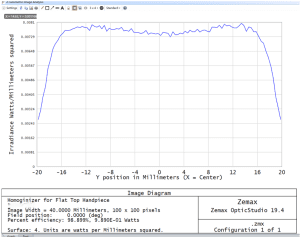

Because the fan angle is relatively small, the product’s material is selected with a low refractive index. The spot uniformity is good, and the uniformity is better than 10% in the range of 80%.

The layout and energy distribution of the Powell lens

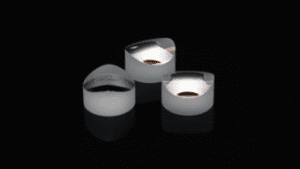

According to the design, the actual product photos are as follows.

Key Considerations for Powell Lens Design

The following factors must be considered when designing a Powell lens:

- Laser wavelength: Powell lenses are designed for specific laser wavelengths. It is important to design a lens to match the laser wavelength you use.

- Line width: How wide the laser line is required for your application

- Line length: How long the laser line is required for your application

- Working distance: The distance from the lens to the workpiece must be considered.

- Beam quality: The quality of the laser beam required must be considered.

Avantier’s Custom Powell Lenses

In conclusion, custom Powell lenses are essential for applications requiring uniform laser line illumination. By focusing on key design indicators like fan angle and incident spot size, these lenses ensure even energy distribution and precise performance. The 30° fan angle Powell lens, designed for a 2.5 mm input beam diameter and visible light wavelengths, exemplifies these principles. Its low refractive index material provides excellent spot uniformity, making it suitable for diverse industrial and research applications. Understanding and optimizing these factors are crucial for achieving the desired laser beam quality and performance in various settings. Contact us today to set up an initial consultation, and get started on your own custom powell lenses.

GREAT ARTICLE!

Share this article to gain insights from your connections!