Key Takeaways:

Top engineers go above and beyond in optical system design optimization. For successful production, consider:

- Manufacturability: Design for high yield by analyzing tolerances and by using easy-to-process components.

- Material Selection: Choose cost-effective materials with short processing times that suit your application.

- Testing and Assembly: Design for active adjustment, testing, and smooth integration with the mechanical structure.

Software Tools for Optical Design

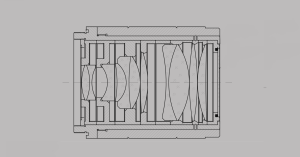

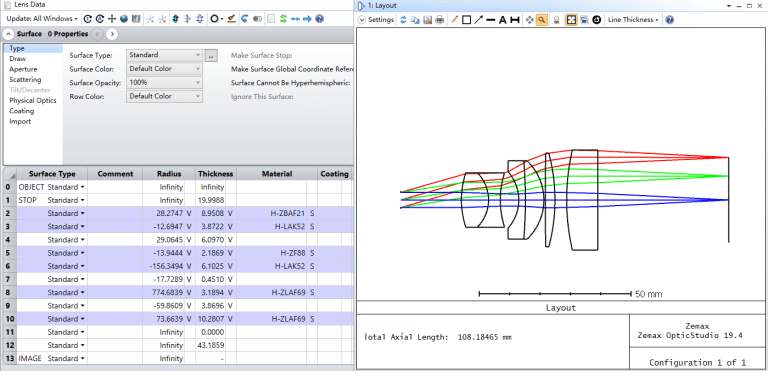

Optical design refers to the design process of optical components and optical systems using optical principles and technologies. Optical design has a long history, and in recent years, due to the development of design software, optical design work has become simpler and more practical. For some relatively simple system requirements, we can choose the appropriate initial structure through the setting of system parameters and evaluation parameters. This allows us to get the design result more easily.

Commonly used optical design software, such as Zemax, provides a very convenient way to evaluate the performance of optical systems, such as Modulation Transfer Function, wavefront difference, spot size, etc. A qualified optical system needs to have the design performance to meet user requirements. However, the satisfaction of design performance is only the first step of optical design. The evaluation of an optical system should be multi-faceted.

Optical System Design Optimization Steps

According to the preliminary design completed by the customer, we can evaluate different aspects, optimize the design in terms of optical system design optimization, or make optimization suggestions. In general, in addition to design performance, we also look at the following aspects:

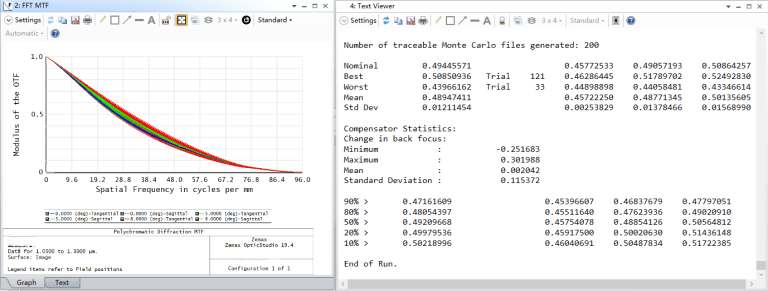

1. Simulation of qualified rate

Because the components used in the design are perfect and without defects, the impact of assembly is not considered. Therefore, it is very likely that the design performance of the system is very good. However, the processed product may not meet the requirements. The simulation of qualification rate is an important part of the design process, especially for complex products with high requirements. The simulation of pass rate is the tolerance analysis of optical systems. Tolerance analysis can objectively evaluate the pass rate of the optical system in the production process and judge the risk of processing production.

For the design with poor tolerance analysis results, the aberration of the sensitive element should be reduced, and the deflection angle of the light should be reduced. The sensitive element may even need to be replaced. A good optical design must be a design that can be put into production, and the impact of components and tolerances should be minimized.

2. Processing of optical components

The optical system is composed of optical components. The difficulty of component processing directly impacts the processing cycle and pass rate of the optical system. It can even affect the progress of the project.

If the designed component cannot be processed, it should be re-optimized. At the same time, in the design process, the number of lenses that are difficult to process and that have a low pass rate should be minimized. For optical systems that need to be actively adjusted, designers should also consider whether the shape of the component will affect the assembly process.

3. Selection of materials

The choice of materials is an important part of the design process. While the optical design software can automatically find optical materials, the designer must still assess if these materials are suitable from various perspectives.

- Choosing cheaper and shorter processing cycle materials is advisable. Otherwise, finding materials may be challenging, increasing the risk of a lengthy system processing cycle.

- The hardness and chemical stability of optical materials impact processing difficulty. Consequently, they influence the cycle and pass rate of lens processing.

- The selection of materials should align with the application scenario. This poses a challenge to the designer’s project experience.

4. Active adjusting and testing

The production and verification of optical systems involves active adjusting and performance testing. If you do not consider how to adjust and test during the design process, the adjustment and test will lose the basis.

Before the optical design is carried out, the processing technology and test content of the actual product should be considered. According to the selected process and test conditions, the optical system is optimized during the design.

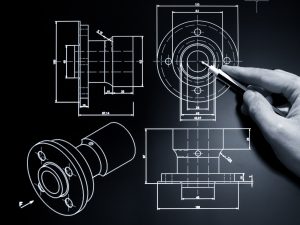

5. Whether it matches the structural design

Before the optical system is put into production, it is necessary to carry out structural design, that is, to complete the mechanical design of the optical system. The optical designer should maintain adequate communication with the mechanical design engineer during the design process. If the initial optical design is difficult for the structural design, it should be improved accordingly.

Key factors of optical system design optimization

In conclusion, optimizing an optical system design goes beyond achieving theoretical performance. A successful design considers manufacturability, material selection, ease of assembly and testing, and compatibility with the final structure. By incorporating these aspects from the beginning, designers can create optical systems that are not only functional but also feasible and cost-effective to produce. We’d be happy to discuss your project! Contact us to schedule a consultation or request for a quote.

GREAT ARTICLE!

Share this article to gain insights from your connections!