Key Takeaways

- Machine vision cameras and custom optics are essential components in automation, enabling machines to perceive and interpret visual data accurately.

- These cameras offer high-speed image capture, excellent resolution, robustness, and various interface options for seamless integration into industrial systems.

- Applications of these cameras include quality inspection, robotics, medical imaging, agriculture, security, automotive, and food industries.

- Avantier contributes to enhancing machine vision cameras through specialized lens design, optimization, filters, coatings, and custom optics tailored to challenging environments.

Unveiling the Role of Machine Vision Cameras in Automation

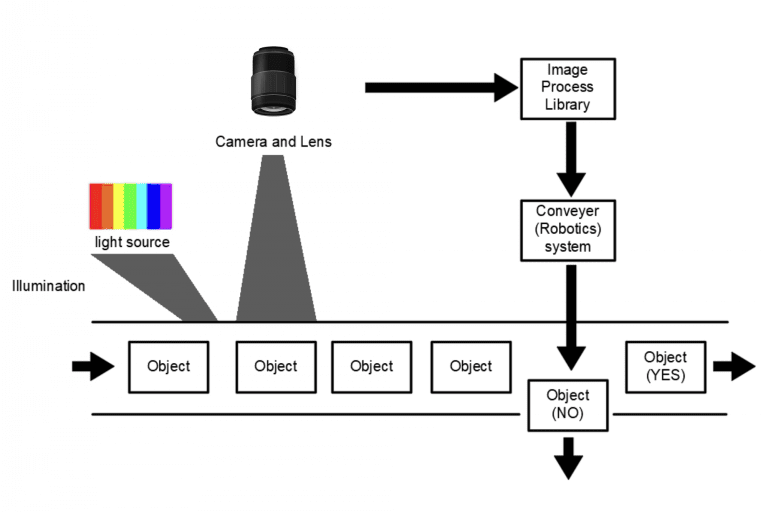

In the world of automation, the ability to see and understand the environment is crucial. Machine vision cameras play a pivotal role in this domain, enabling machines to perceive and interpret visual information like never before. These sophisticated cameras, combined with custom optics, have opened up a world of possibilities across various industries. In this article, we will explore what machine vision cameras are, delve into their applications, and discuss how Avantier can contribute to enhancing their performance.

What Are Machine Vision Cameras?

Machine vision cameras, often referred to as industrial cameras, are specialized imaging devices designed for capturing and processing visual data in industrial and automation settings. Unlike traditional consumer cameras, machine vision cameras are engineered for precision, speed, and reliability. They are a fundamental component of computer vision systems and are used in conjunction with advanced software to analyze and make decisions based on the images they capture.

Key Characteristics of Machine Vision Cameras:

- High Speed: They can capture multiple images per second, allowing real-time analysis and decision-making in fast-paced industrial environments.

- High Resolution: They offer excellent image quality and sharpness, enabling the detection of fine details and defects.

- Robustness: These cameras are built to withstand harsh industrial conditions, including extreme temperatures, vibrations, and dust.

- Monochrome and Color Options: They come in both monochrome and color variants, catering to a wide range of applications.

- Interface Options: They support various interfaces like USB, GigE Vision, and Camera Link for seamless integration into different systems.

Applications of Machine Vision Cameras

Machine vision cameras find applications across diverse industries due to their ability to improve quality control, enhance efficiency, and reduce operational costs. Here are some notable applications:

- Quality Inspection: They are extensively used for inspecting products on manufacturing lines. They can identify defects, measure dimensions, and ensure products meet stringent quality standards.

- Robotics and Automation: In robotics, these cameras provide robots with the ability to perceive their surroundings, making them capable of tasks such as pick-and-place operations, assembly, and navigation.

- Medical Imaging: These cameras are employed in medical diagnostics, aiding in procedures like endoscopy, retinal imaging, and tissue analysis. They enhance the accuracy and precision of medical professionals.

- Agriculture: These cameras assist in crop monitoring, sorting produce, and detecting diseases in plants. They contribute to increased crop yields and reduced resource wastage.

- Security and Surveillance: In security systems, these cameras help in facial recognition, license plate recognition, and monitoring critical areas for unauthorized access.

- Automotive Industry: These cameras are integral to autonomous vehicles, assisting in obstacle detection, lane keeping, and traffic sign recognition.

- Food and Beverage: They are used for quality control in food production, ensuring products meet safety and quality standards.

How Avantier Contributes to Better Machine Vision Cameras

Avantier plays a vital role in enhancing the performance of these cameras. Custom optics are precision-crafted optical components tailored to meet a particular application’s specific needs. Here’s how these companies contribute to improving machine vision:

- Lens Design and Optimization: Avantier designs and manufactures specialized lenses that optimize the image quality and field of view for machine vision cameras. These lenses can reduce distortion, aberrations, and other optical imperfections, resulting in sharper and more accurate images.

- Filters and Coatings: These cameras often require filters and coatings to enhance their sensitivity to specific wavelengths or to reduce glare and reflections. Avantier develops and supplies these components to improve image clarity and quality.

- Specialized Optics for Challenging Environments: In industries with demanding environmental conditions, such as semiconductor manufacturing or underwater exploration, Avantier can develop optics that can withstand extreme temperatures, pressure, or corrosive environments.

Conclusion

Machine vision cameras are the eyes of modern automation, enabling machines to see and understand the world around them. Their applications span across various industries, from manufacturing and healthcare to agriculture and security. Avantier plays a crucial role in improving the performance of machine vision cameras by designing specialized optics that enhance image quality, accuracy, and reliability. As technology advances, the partnership between machine vision cameras and Avantier promises to unlock even greater precision and innovation in the field of automation.

GREAT ARTICLE!

Share this article to gain insights from your connections!