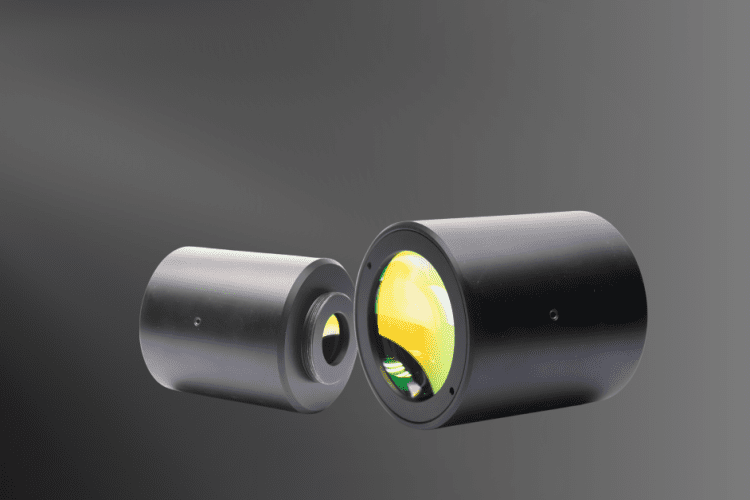

Avantier is a leading expert in crafting high-performance in-stock IR Lenses, and we offer a wide selection of in-stock IR Lenses to meet your needs. These in-stock IR lenses excel in the realm of infrared applications and are invaluable in various industries.