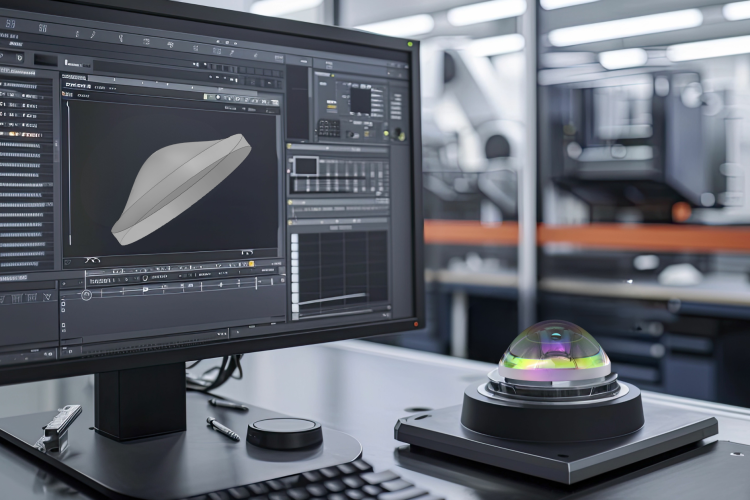

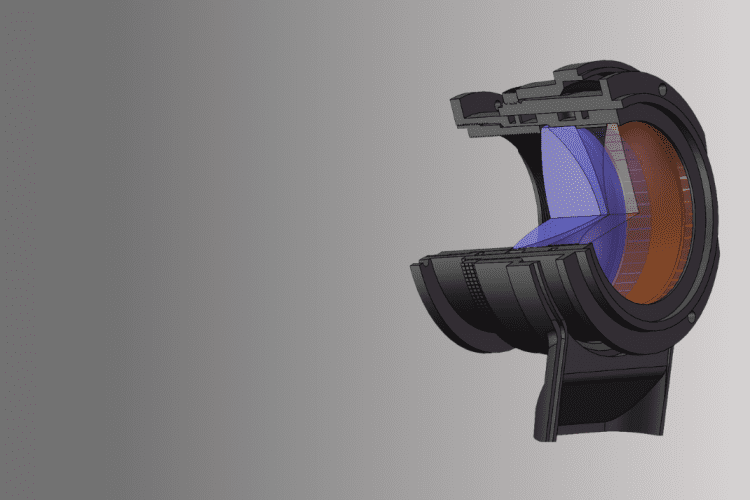

Key Takeaways This Aspherical Lenses Reverse Engineering case study details the reverse engineering of a double aspherical lens used in laser cutting systems. By precisely measuring geometry, modeling surface equations, and analyzing material and coatings, Avantier reduced R&D time by over 60% and cut costs by 50%. Advanced tools like interferometers, profile meters, and Zemax […]