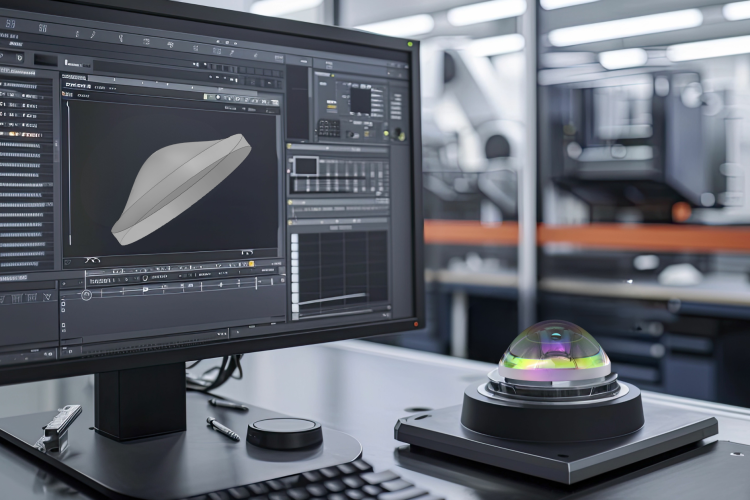

Case Study: Achieving Exceptional Thermal Stability with CFRP in Space Telescopes

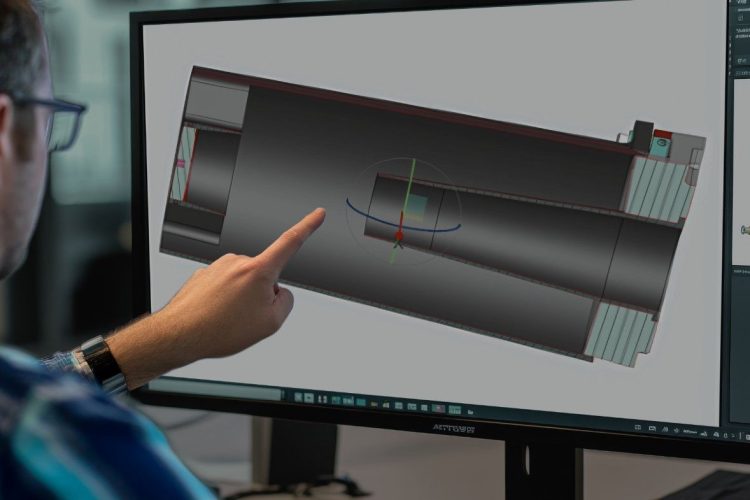

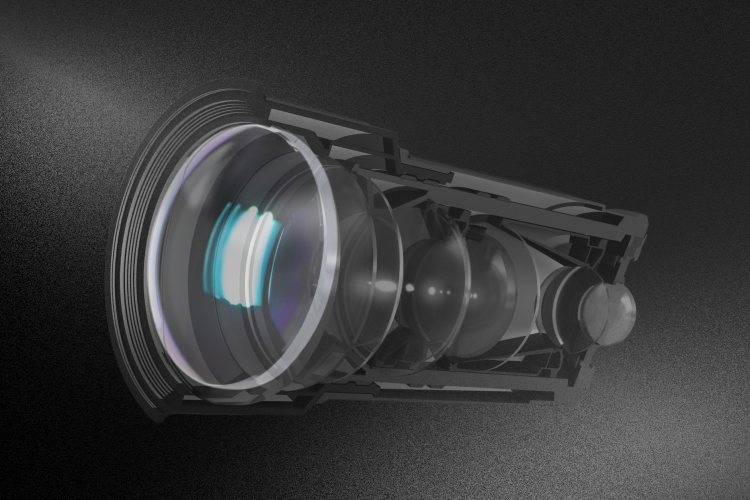

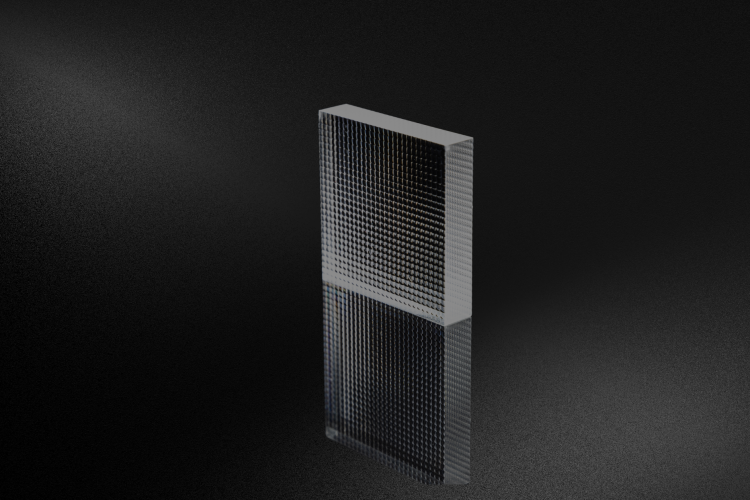

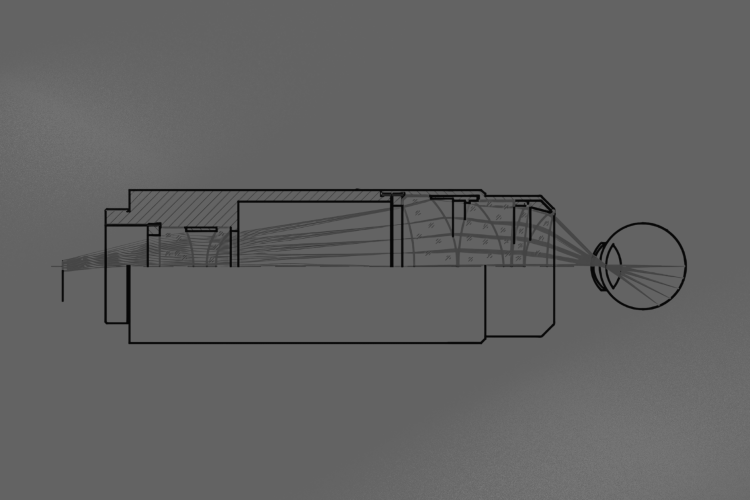

To ensure mission success in harsh environments, we optimized a high-performance imaging system by prioritizing thermal stability with CFRP. This case study details how replacing traditional materials with carbon fiber and refining assembly techniques delivered a lightweight, stable, and flight-ready optical system.