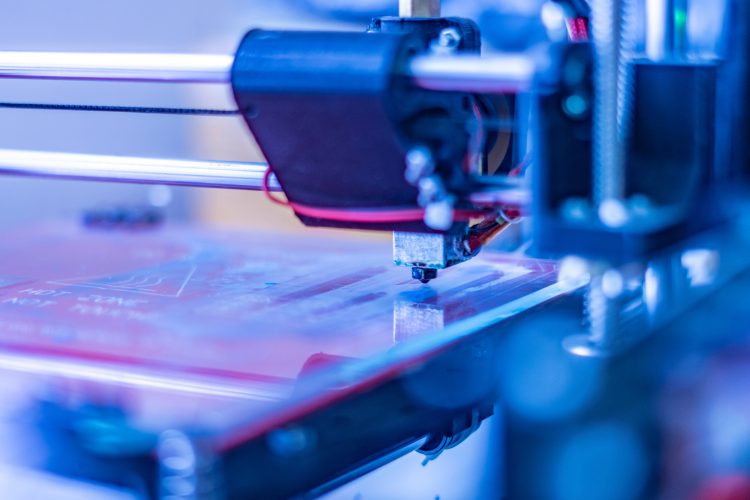

Key Takeaways: Micro- and nano-scale 3D printing transforms microlens fabrication with high-resolution, mold-free production and rapid prototyping. This manufacturing method works well with diverse materials and enables multifunctional optics like GRIN and tunable lenses. Key applications of 3D printed microlenses include biomedical imaging, OCT, flow cytometry, optical sensing, fiber optics, and laser beam shaping. Mofang […]