KeyTakeaways

- Finite conjugate microscope objectives provide compact, stable, and cost-effective high-resolution imaging for industrial inspection, micro-nano machining, and portable diagnostic systems.

- Their fixed-distance design delivers excellent NA, precise aberration control, and reliable performance across UV, visible, and IR applications.

- While less flexible than infinity-corrected systems, finite conjugate objectives excel in integrated OEM instruments and space-constrained environments where optical simplicity, durability, and imaging precision are critical.

Achieving high-resolution imaging in environments with limited space, tight budgets, or integrated optical constraints is a major challenge. Finite distance (finite conjugate) microscope objectives—a long-established but highly capable optical architecture—remain one of the most efficient solutions.

Rather than competing with infinity-corrected systems, finite conjugate objectives excel in applications requiring compactness, stability, and cost-effective excellence, making them indispensable in industrial inspection, portable diagnostics, and micro-nano machining.

1. Understanding Finite Conjugation: How It Differs from Infinity-Corrected Systems

In optical design, conjugation refers to the point-to-point mapping between an object plane and its corresponding image plane.Infinite Conjugate Objectives

- Project the specimen to optical infinity, producing a parallel light path.

- Require a separate tube lens to form the final image.

- Allow filters, beam splitters, and modulators to be inserted into the parallel beam without degrading imaging performance.

- Offer versatility but at the cost of higher system complexity and expense.

Finite Conjugate Objectives

- Form a real image directly behind the objective at a fixed distance (commonly 160 mm for DIN systems).

- The single-stage imaging design creates:

- Shorter optical paths

- Higher rigidity and stability

- More compact and cost-efficient systems

- Widely used in integrated instruments and industrial systems where mechanical simplicity matters.

2. Operating Principle and Key Optical Performance Parameters

A finite-conjugate objective operates through a fixed optical workflow: light collection → aberration correction → real image formation The objective gathers light via the front group, corrects aberrations using a precisely engineered lens assembly, and forms a stable intermediate image at the end of the mechanical tube length.Four Core Parameters Define Finite-Conjugate Performance

2.1 Numerical Aperture (NA): The Basis of Resolution

- Determines light-gathering ability and theoretical resolving power.

- Oil immersion finite objectives can exceed NA 1.4, reaching the limits of classical optical microscopy.

2.2 Resolution: Revealing Micro- and Nano-Scale Detail

Derived from Abbe’s diffraction limit: High-NA finite objectives combined with short-wavelength illumination (e.g., UV) offer sub-micron resolution, allowing visualization of organelles, fine surface textures, and micro-fabricated structures.2.3 Aberration Correction

Finite objectives range from:- Achromats (basic color correction)

- Plan-achromats (flat-field correction)

- Advanced multi-element apochromats

- Low chromatic aberration

- Reduced field curvature

- High image uniformity

2.4 Working Distance (WD): Application Flexibility

Working distance varies dramatically:- ~10–30 mm for low magnification (4×, 10×)

- <0.1 mm for high-magnification oil-immersion lenses

- In-vivo sample manipulation

- Machine vision inspection

- Laser processing and micro-machining

3. Optical and Mechanical Design Philosophy: Precision Under Constraints

Finite-conjugate objectives achieve performance through careful balancing of optical design, mechanical rigidity, and cost optimization.

3.1 Optical Structure Engineering

Low-magnification lenses (4×, 10×):

- Use 2–3 cemented groups

- Correct spherical and chromatic aberrations

- Prioritize long working distance and wide fields of view

Medium magnification (20×, 40×):

- Add additional elements and special shapes (e.g., crescent lenses)

- Improve NA and enhance aberration control

High-magnification oil immersion (100×):

- Most complex, typically 6–8 lens elements

- Symmetric or semi-symmetric arrangements

- Designed for extreme NA and minimal aberration

Reflective Finite Telephoto Designs

For UV/IR work (200–11,000 nm), reflective objectives eliminate glass-based chromatic dispersion using:- Concave/convex mirror combinations

- Broadband performance across wide spectral ranges

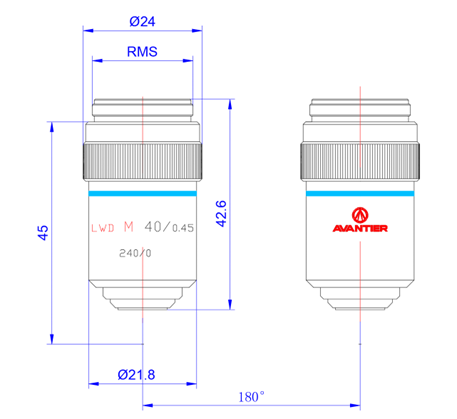

3.2 Mechanical Structure: Rigid, Stable, and Calibration-Free

Key characteristics:- Precision-machined metal barrels

- Standardized RMS threads for universal compatibility

- Coaxial alignment ensured by tight positioning surfaces

- Lenses held by compression rings or bonded assemblies

- Vibration

- Thermal drift

- Shock

Manufacturing Advantage

Finite objectives are simpler than infinity-corrected objectives:- No need to account for downstream optics in a parallel beam

- Looser tolerance stacking

- Lower overall production cost

- Educational microscopes

- Budget-conscious scientific tools

- Integrated OEM systems

3.3 Technical Limitations

Despite their strengths, finite-conjugate systems have known constraints:1. Fixed Optical Path

Adding filters, beam splitters, or optical modules shifts the image plane, causing:- Defocus

- Aberrations

- Magnification errors

2. No Flexible Magnification

Infinity systems adjust magnification via tube lens focal length; finite systems cannot.

3. Limited Use in Advanced Modalities

Not ideal for:- Confocal microscopy

- Fluorescence lifetime imaging

- Complex laser-based optical paths

4. Application Areas: Where Finite-Conjugate Objectives Excel

Finite-conjugate microscope objectives play an important role across industry, research, and micro-fabrication.

4.1 Industrial Inspection & Machine Vision

Used for:- PCB inspection

- Semiconductor quality control

- Medical device evaluation

- Compact imaging modules

- High resolution

- Low cost

- Stable, vibration-resistant imaging

4.2 Life Science Imaging & Portable Diagnostics

Finite objectives enable:- Portable fluorescence microscopes

- Field-deployable diagnostic devices

- Point-of-care analyzers

- Lightweight

- Low power consumption

- Durable

- High clarity without bulky optics

4.3 Micro-Nano Machining & Laser Processing

In femtosecond and ultrafast laser applications, objectives must focus beams to diffraction-limited spots. Finite objectives offer:- High NA for tight focus

- Excellent aberration control

- Reliable energy delivery

- Glass engraving

- Precision cutting

- Micro-structuring of semiconductor materials

4.4 UV & IR Broadband Imaging

Reflective finite objectives support wavelengths from 200 nm to 11,000 nm, making them ideal for:- FTIR systems

- UV lithography

- Deep-UV spectroscopy

- IR material characterization

5. Conclusion

Finite distance conjugate microscope objectives remain foundational elements of modern optical engineering. Their unmatched combination of:- Compact structure

- High imaging performance

- Mechanical stability

- Cost efficiency

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!