Key Takeaways

- A defense client required a 300 mm MgF₂ dome for airborne optical systems, demanding ≥80% transmission up to 5 µm.

- Major challenges included high raw material cost, fracture risk in machining, stringent bonding prep, and short lead time.

- Avantier optimized bonding design, introduced controlled roughness zones. These solutions cut fracture risk, boosted yield by over 20%, and preserved pricing despite design complexity.

Project Background: Large-Aperture Infrared Dome for Airborne Systems

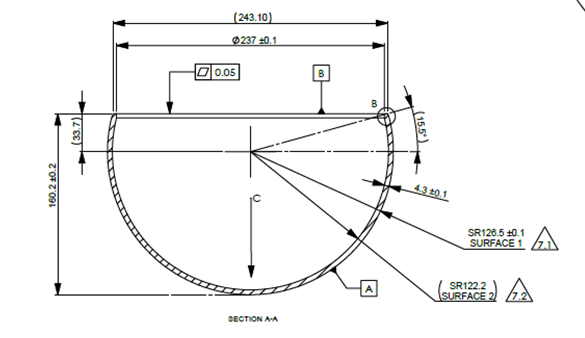

A defense industry customer approached us to evaluate the feasibility of producing a large-format infrared dome from hot-pressed magnesium fluoride (MgF₂) (Figure 01). The dome was intended for integration into an airborne optical system requiring VIS-IR transmission up to 5 µm, exceptional surface quality, and durable bonding to a fiberglass lower adapter.

Given the size (Ø 300 mm) and precision requirements, the project demanded specialized manufacturing processes, careful raw material utilization, and early-stage design collaboration to balance performance, manufacturability, and cost.

Challenges in Designing and Manufacturing the MgF₂ Dome

- Optical Performance Requirements

The dome needed ≥80% transmission up to 5 µm without coating and potential AR coating from 0.3–5 µm optimized for 4–5 µm. Achieving this required high-purity MgF₂ with no stress birefringence (n=1.3812) and precise control of optical surface figure and finish. - Material and Cost Constraints

Large MgF₂ blanks are costly, with low yield rates. A single fracture during processing could result in significant loss. Maintaining the original quoted price while meeting tight specs added financial pressure. - Mechanical and Thermal Demands

The bonding interface had to meet shear strength ≥15 MPa at −40 °C and room temperature, and ≥2 MPa at 200 °C. This necessitated careful adhesive selection and surface preparation to ensure performance in airborne operational conditions. - Machining Risk

The customer’s initial design included an internal step, which posed a high fracture risk during internal grinding operations.

Solutions and Outcomes

- Bonding Interface Optimization

We recommended moving the step to the external surface to enlarge the bonding area and eliminate the fracture risk from internal milling. - Controlled Surface Roughness Zones

Three bonding zones (bottom flat, outer sphere 8 mm from base, inner sphere 8 mm from base) were prepared with Ra 0.8–1.6 µm to maximize adhesive performance. Optional 0.012 µm polish was offered for optical interface applications. - Early Evaluation Coupons

To meet the need for rapid evaluation, we proposed smaller test coupons (180×180 mm or 200×200 mm) deliverable in 30–35 days, compared to 50 days for full-size plates. - Precision Fabrication and Inspection

Surface figure was measured via interferometry for convex surfaces and matched templates for concave surfaces. Full dimensional inspection reports were included before shipment.

Results

- Fracture Risk Eliminated: External step design reduced machining hazard.

- Yield Improvement: Optimized blank preparation and machining predicted >20% higher acceptance rate.

- Operational Compliance: Adhesive and surface prep met shear and thermal cycling requirements.

Conclusion: Precision MgF₂ Dome for Airborne Optical Systems

By overcoming the challenges of material cost, fracture risk, and bonding performance, we successfully delivered a precision MgF₂ hyperspherical dome optimized for airborne optical systems. The combination of design innovation, surface preparation, and risk mitigation strategies not only improved yield but also ensured reliable operation under extreme conditions. This project underscores our capability to engineer large-aperture optics with both technical precision and cost efficiency, setting a benchmark for future airborne defense applications.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!