Key Takeaways

- Avantier engineered a custom 75° underwater lens assembly for subsea imaging, achieving an exacting ±0.03 mm back-focus tolerance.

- Through underwater resolution testing and iterative optical adjustments, the lens delivered uniform sharpness from center to edge.

- Validated in real subsea conditions, it supports ROVs, AUVs, offshore inspections, defense applications, and marine research.

- This project demonstrates Avantier’s expertise in precision engineering, environment-specific testing, and delivering mission-ready optical solutions that meet the stringent performance demands of critical underwater imaging applications.

Project Overview: Engineering a Custom Underwater Lens Assembly for Subsea Imaging

A leading provider of subsea imaging solutions approached Avantier to develop a custom 75-degree underwater lens assembly optimized for use with a 2/3-inch sensor camera. The lens was designed for a working distance of approximately 1.5 meters, ensuring exceptional imaging performance in demanding subsea environments.

Because the refractive index of water differs significantly from air, performance validation required full underwater testing to ensure the lens would meet its stringent operational requirements.

Customer Requirements

The most critical challenge was meeting an extremely tight back-focus tolerance of ±0.03 mm. Even minor deviations from this specification could significantly degrade optical performance. Our engineering team employed precision shimming during assembly to maintain exact optical spacing and alignment.

Target Market & Applications

This lens was engineered for high-accuracy underwater imaging across a variety of subsea applications, including:- Subsea exploration – remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs).

- Offshore energy – inspection of pipelines, subsea cables, and platform structures.

- Defense & naval operations – secure and dependable underwater imaging.

- Marine research – high-resolution data capture for scientific studies.

Engineering Challenges & Solutions

1. Realistic Underwater Testing

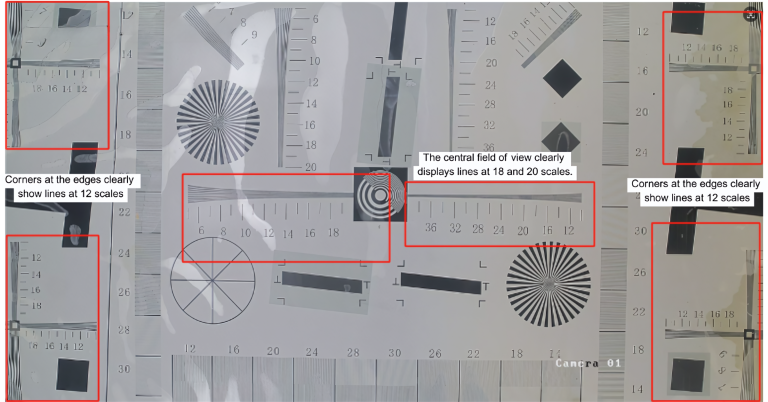

Testing the lens in air would yield misleading results due to different refractive conditions. To accurately replicate real-world usage, we conducted underwater resolution testing using the ISO12233 Standard Resolution Chart. Process:- A large water tank was prepared, with the ISO12233 chart placed at the bottom.

- The lens was mounted on a precision bracket and submerged 0.5 meters below the chart.

- Images were captured and analyzed for aberration and resolution clarity.

2. Iterative Optical Debugging

Following each test, the lens was dried, disassembled, and internal lens spacing and eccentricity adjustments were made to optimize performance. The lens was considered qualified only if it met both conditions:- Center field of view – clear resolution at 18 and 20 scales.

- Edge corners – clear resolution at 12 scales.

Performance Validation

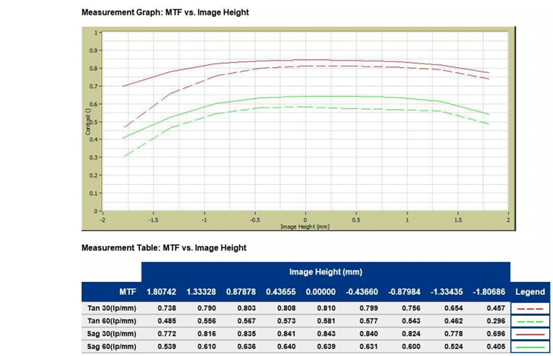

While MTF (Modulation Transfer Function) testing provided valuable quantitative data, final approval was based on underwater imaging results. This ensured performance was validated under the same conditions in which the lens would operate in the field.

Results

The final product achieved:- 75° × 75° field of view with excellent corner sharpness.

- f/2.8 aperture and 5mm focal length supporting 2.74 μm pixels.

- Back-focus alignment within ±0.03 mm.

- Verified high-resolution imaging performance in true subsea conditions.

Impact: Advancing Subsea Imaging Through Precision Underwater Lens Assemblies

This project highlights how precision engineering, environment-specific testing, and iterative refinement can deliver optical assemblies that meet the stringent demands of subsea industries. The result is a mission-ready underwater lens that provides consistent, high-resolution imaging for critical applications.

Ready to achieve unmatched clarity in subsea imaging? Our engineering team specializes in designing and testing custom underwater optics that meet the tightest tolerances and perform flawlessly in real-world conditions. Whether you’re developing ROVs, AUVs, or specialized inspection systems, Avaniter can deliver precision-engineered lens solutions tailored to your mission requirements. Contact us today to discuss your project and explore how we can enhance your underwater imaging capabilities.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!