Key Takeaways

- Finite Conjugate Tube Lens Design plays a critical role in precision imaging for microscopy and inspection, addressing unique challenges where objects lie at finite distances.

- Unlike infinity-corrected systems, this tube lens design ensures optimized conjugate distance, aberration control, and magnification stability.

- The case study highlights the development of a high-performance finite conjugate tube lens with a symmetrical optical layout and modular barrel for cost efficiency and assembly ease.

- Importantly, such designs remain vital for applications with ultra high NA objectives, enabling superior imaging in biomedical, industrial, and materials science fields.

Introduction to Finite Conjugate Tube Lens Design

In precision optical imaging, particularly in biological microscopy and industrial inspection, the finite conjugate tube lens plays a vital role. Unlike infinity-corrected optical systems, which are now more common, finite conjugate systems are specifically designed for scenarios where the object is at a finite distance rather than at infinity. This design addresses unique imaging challenges in specialized applications.

This case study examines the optical principles of finite conjugate tube lenses, their application scenarios, and the specific design, manufacturing, and optimization journey — a high-performance finite conjugate tube lens developed to meet demanding imaging requirements.

1. Understanding Finite Conjugate Tube Lenses

Optical Conjugates

An optical conjugate refers to a pair of points in an optical system — one in object space and one in image space — where light emitted from the object point converges precisely onto the image point. The object plane and image plane are thus conjugate planes.Infinity-Corrected vs. Finite Conjugate Systems

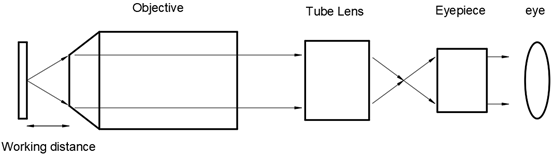

- Infinity-Corrected Systems: The objective lens projects the object plane to infinity. Light rays exit the objective as parallel beams and require an infinity-corrected tube lens to focus onto the detector or eyepiece. This configuration is common in modern microscopes.

- Finite Conjugate Systems: The objective directly forms a real intermediate image at a fixed finite distance. A finite conjugate tube lens then relays or re-images this intermediate image to the detector or eyepiece.

2. Optical Design Considerations

Finite conjugate tube lenses differ from infinity-corrected lenses in several key aspects:

- Conjugate Distance Constraints – The lens must precisely match the intermediate image plane position and final image plane position.

- Image Quality – Aberrations such as spherical, coma, astigmatism, field curvature, distortion, and chromatic aberrations must be minimized.

- Magnification Control – Tube lens magnification (e.g., 1×, 2×) directly impacts total system magnification.

- Working Distance – Adequate space must be available for accessories such as filters, beam splitters, or scanning devices.

3.Why Choose Finite Conjugate Systems?

While infinity-corrected systems are standardized and flexible, finite conjugate systems excel in scenarios such as:

- Thick Sample Imaging: With correction collar objectives, they can compensate for spherical aberrations caused by varying cover slip or dish thickness.

- Complex Optical Paths: Enable flexible intermediate image placement for large optical modules or relay optics.

- Legacy Compatibility: Support older finite conjugate-based instruments.

- High-Performance Objectives: Certain ultra-high-NA or long-working-distance objectives require finite conjugate configurations.

4. Core Application Areas

- Biomedical Research: Live-cell imaging, deep-tissue imaging, fluorescence microscopy.

- Industrial Inspection: Semiconductor wafers, flat-panel displays, transparent materials.

- Materials Science: Samples encapsulated in transparent media.

5. Case Study

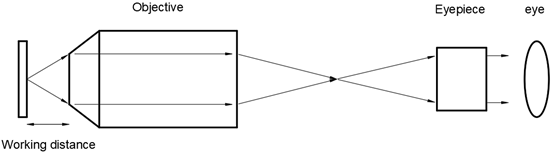

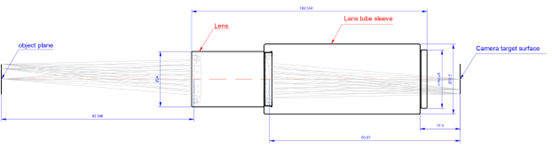

A customer from the biotechnology industry was seeking a finite conjugate tube lens specifically designed to receive the intermediate real image from the objective and relay it to the final detector.Optical Design

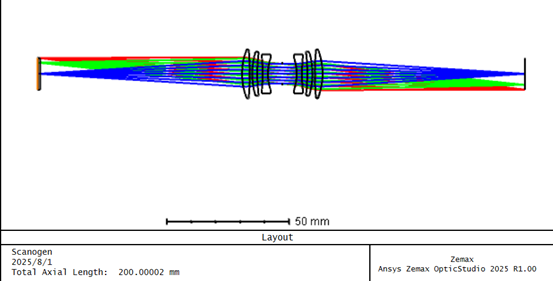

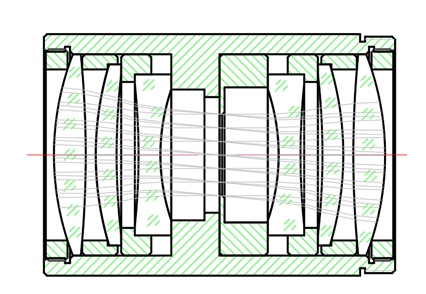

- Six-Element Symmetrical Layout: To reduce manufacturing cost without compromising performance, the six individual elements were grouped into three cemented doublets. This symmetrical arrangement provides the same optical quality while simplifying assembly and reducing cost.

Mechanical Design Optimization

- Symmetrical Mechanical Structure: The mechanical housing mirrors the optical symmetry, reducing the number of spacer and pressure ring designs by 50%, cutting production cost.

- Long Rear Focal Length Challenge:

To connect directly to a camera mount, the lens required a barrel length of ~102.5 mm. This introduced manufacturing issues:

- Maintaining concentricity and roundness in deep bores was difficult, lowering yield.

- Lens assembly into a deep bore was inefficient.

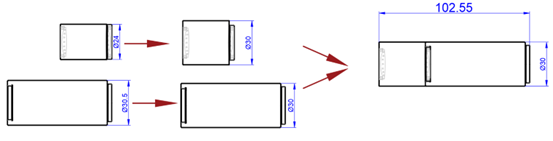

Solution: The barrel was split into two modular segments — the main barrel body and a connecting tube. This modular design simplified manufacturing, improved assembly efficiency, and reduced cost.

Second-Generation Improvements

The second-generation lens kept identical optical performance but introduced aesthetic and ergonomic refinements:- Increased the barrel diameter and reduced the connecting tube diameter to achieve a uniform, visually harmonious profile.

- Maintained complete interchangeability with the first generation.

Result: The updated design is more attractive, easier to assemble, and fully backward-compatible.

6. Advantages and Limitations of Finite Conjugate Tube Lenses

Advantages:

- Exceptional spherical aberration correction for thick samples (with correction collar objectives).

- Flexible optical path integration.

- Compatibility with specialized or legacy objectives.

Limitations:

- Requires precise optical matching between the objective and tube lens.

- Lower standardization across manufacturers.

- Higher cost for specialized objectives and lenses.

- Careful handling of inserted components to avoid aberration introduction.

Advancing High-Performance Finite Conjugate Tube Lens Design for Ultra High NA Objectives

The lens demonstrates how careful optical and mechanical design can optimize a finite conjugate tube lens for both performance and manufacturability. By combining symmetrical cemented doublets with a modular barrel design, this case achieves:

- High imaging performance,

- Lower production cost,

- Improved assembly efficiency, and

- Enhanced visual design.

Finite conjugate tube lenses like this case remain essential in cutting-edge microscopy and industrial inspection, particularly where thick sample imaging and aberration correction are critical. As imaging demands push toward higher resolution and more complex optical paths, these lenses will continue to be indispensable tools in advancing both scientific discovery and precision manufacturing.

Let’s design it together. Contact Our Optical Design Team!

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!