Key Takeaways

- A leading medical laser manufacturer upgraded from plano-convex to germanium meniscus lenses, achieving enhanced focal accuracy.

- Challenges included optimizing aberration correction, ensuring infrared compatibility, and managing thermal sensitivity for reliable performance.

- Germanium meniscus lenses improved beam shaping and system reliability, enabling precise energy delivery for applications like laser surgery and thermal imaging.

- The upgrade enhanced system integration, reducing operational downtime and improving versatility across medical procedures.

Project Background: Germanium Meniscus Lenses for Medical Laser Systems

A global leader in medical laser technology, renowned for its cutting-edge surgical and diagnostic systems, partnered with us to enhance their laser systems’ optical performance. The goal was to replace outdated plano-convex lenses with advanced germanium meniscus lenses to achieve superior aberration correction, sharper imaging, and compatibility with infrared (IR) applications critical for procedures like laser surgery and thermal diagnostics.

Challenges in Designing and Manufacturing Germanium Meniscus Lenses

- Optimizing Optical Performance

Meniscus lenses are ideal for correcting spherical aberrations, delivering sharper focal points. The challenge was designing a germanium meniscus lens to improve focal accuracy for high-precision medical applications, such as minimally invasive surgeries. - Ensuring Infrared Compatibility

The system required high transmittance in the infrared range, essential for thermal imaging and laser therapies. The lens design needed to maintain an optimized refractive index for IR wavelengths without compromising signal clarity. - Managing Thermal Sensitivity

Germanium’s transmittance decreases at elevated temperatures, posing a risk to performance in dynamic medical environments. Ensuring thermal stability was critical to maintain consistent laser output during prolonged procedures. - Achieving Precision Beam Shaping

The lens needed to enhance beam shaping for precise energy delivery, improving control in applications like tissue ablation. Seamless integration into the existing system without compromising precision was a key requirement.

Solutions and Outcomes

- Advanced Aberration Correction

Using state-of-the-art optical design, the germanium meniscus lens significantly reduced spherical aberrations, delivering sharper focal spots and enhanced imaging quality. - Optimized Infrared Performance

Germanium is specifically designed for infrared applications, with excellent transmission in the 2–16 μm wavelength range. The lens was engineered to ensure reliable performance for IR-based applications, strengthening the system’s ability to handle thermal sensing and laser therapies with minimal signal loss. - Enhanced Thermal Stability

By incorporating temperature compensation mechanisms, the lens maintained consistent performance across varying temperatures, reducing downtime in demanding medical environments. - Precision Beam Shaping and Integration

The meniscus lens enhanced beam shaping, enabling improved control of energy delivery. Seamless integration into the customer’s system increased overall efficiency, supporting a wide range of applications.

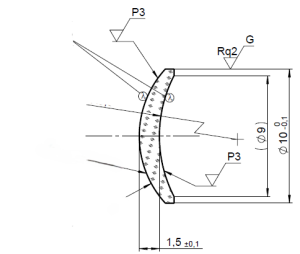

- Diameter (ø): 10mm and Thickness: 1.5mm

- Reflectance: < 5%

- Wavelength Range: 3-12 µm

- Roughness: < 2 µm

Impact and Next Steps

The integration of germanium meniscus lenses has set a new standard in medical laser systems, enhancing optical precision, thermal stability, and beam shaping. This upgrade improved focal accuracy, reduced operational downtime, and optimized energy delivery, making the system more versatile across medical applications.

This collaboration strengthens the customer’s leadership in medical laser technology and paves the way for future innovations, transforming minimally invasive procedures and diagnostic imaging.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!