Key Takeaways

- Light manipulation in laser systems and optical systems relies on precision micro prisms to control light effectively.

- Micro prisms improve image quality and focusing in compact devices like digital cameras and medical instruments.

- Advanced micro-fabrication and coating techniques optimize micro prism performance and cost-effectiveness.

- Customer collaboration ensures tailored micro prism solutions for specific applications and requirements.

Precision Light Control with Micro Prisms

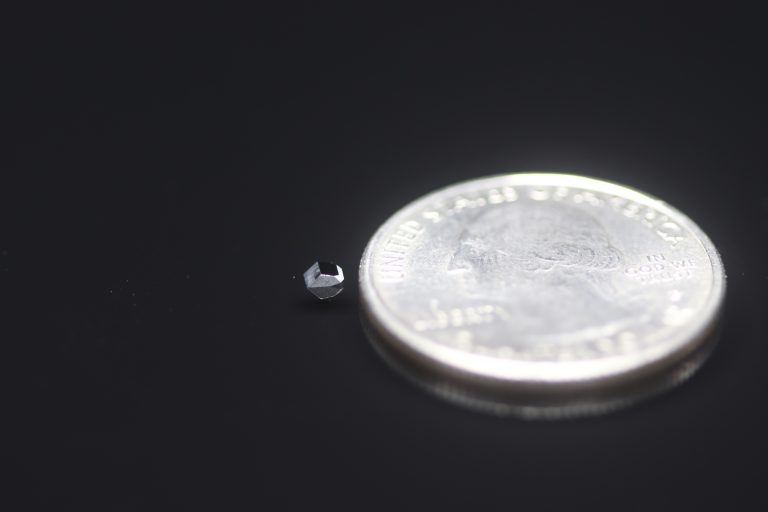

Micro prisms are a key technology in optics, enabling precise light manipulation at very small scales. They are tiny optical components made of transparent materials like glass or plastics, with precise surfaces that can refract or reflect light in specific ways. They are often used in various applications such as imaging devices, laser systems, and optical sensors.

The design of micro prisms allows for control over the direction and behavior of light rays at a microscopic level, enabling functionalities like focusing, collimating, or dispersing light. These prisms can be integrated into compact optical systems, making them useful in miniaturized devices such as digital cameras, projectors, and medical instruments.

One common application of micro prisms is in digital cameras and smartphone cameras, where they help improve image quality by correcting aberrations and enhancing focusing capabilities. Additionally, micro prism optical elements are used in laser systems for beam shaping and alignment tasks.

Project Overview

This project that was undertaken by Avantier’s customer aims to develop and manufacture micro prism lenses for various optical applications. Micro prism technology allows for precise manipulation of light at microscopic scales, enabling functionalities like focusing, collimating, and dispersing light.

Project Goals

- Develop micro prism lenses with high precision and performance.

- Ensure compatibility with various optical systems and devices.

- Optimize manufacturing processes to meet quality standards and cost-effectiveness.

- Collaborate with customers to tailor solutions for specific applications and requirements.

Throughout the project, several key goals were achieved:

- Precision and Performance: The project successfully developed micro prism lenses with high precision and performance, meeting the demanding requirements of various optical systems and devices.

- Compatibility: Efforts were made to ensure compatibility with a wide range of optical systems and devices, allowing for seamless integration and versatility in applications.

- Optimization: Manufacturing processes were optimized to meet stringent quality standards while ensuring cost-effectiveness. Utilizing advanced micro-nano fabrication techniques and coating technologies enabled the production of high-quality lenses.

- Customer Collaboration: Collaboration with customers played a crucial role in tailoring solutions to specific applications and requirements. By understanding customer needs and feedback, the project was able to deliver customized optical solutions.

Micro Prism Specification

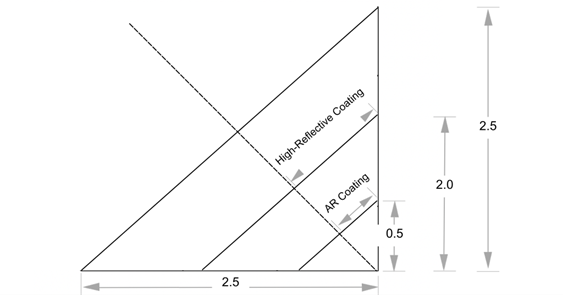

Material | Schott N-LASFOhara S-LAH |

Dimension (W x D x H) | 2.5 x 2.5 x 2.5 mm |

Coating | High-reflective Rav 95%mirror(S1)AR-coating Rav < 0.8% @ 450-1000 nm |

Manufacturing Capability by Avantier

- Micro-Fabrication: Achieving the miniature size (2.5 x 2.5 x 2.5 mm) with high precision demanded a multi-pronged approach. We employed advanced micro-nano fabrication techniques such as laser cutting or precision CNC machining. This ensured dimensional precision for both lenses and prisms.

- High-Reflective Lens Coatings: Manufacturing lenses with high reflectivity (S1) presented a challenge due to the need for specialized coating technology and consistent micro-scale results. To overcome this, we utilized advanced vacuum deposition techniques like PVD or CVD. These techniques allowed for the deposition of high-reflectivity metallic or dielectric thin films.

- Anti-Reflective Coatings: To achieve anti-reflective (AR) coatings with minimal reflection losses (Rav < 0.8% @ 450-1000 nanometers), we employed multilayer film stack technology. This technique allows for the deposition of thin films with varying refractive indices on the lens surface. We further optimized the coating structures using optical thin-film design software, ensuring precise control of coating thickness.

- Assembly and Testing: Precise handling is crucial when assembling micro prism lenses to guarantee accurate alignment and secure connections between the delicate optical components. We addressed this challenge by employing automated assembly equipment for consistent results. Additionally, precision operations under a microscope ensured correct positioning and fit. Rigorous testing with measurement devices for parameters like transmittance and reflectance followed to confirm compliance with specifications.

Conclusion

This project represents a significant achievement in the advancement of optical technology, particularly in the tailoring of high-quality micro prism lenses to specific applications. Through collaboration, innovation, and optimization, the project has successfully addressed the challenges of manufacturing micro prism lenses and has paved the way for future advancements in the field of optics.

GREAT ARTICLE!

Share this article to gain insights from your connections!