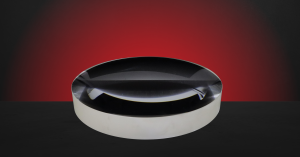

In advanced optical engineering, where precision and performance are pushed to the physical limit, a reliable planar reference defines the success of an entire system. We specialize in manufacturing large-aperture, high-precision flat mirrors that serve as both optical and structural foundations for high-end applications. From astronomical telescopes to high-energy laser systems, our ultra-precision machining and comprehensive metrology deliver optical performance with exceptional accuracy and stability.

1. Core Advantages: Accuracy and Reliability as System Foundations

1.1 Cornerstone of System Accuracy

Our large-aperture mirrors provide an almost ideal reference plane with excellent surface flatness and optical quality. They can be directly used for system calibration and alignment, improving installation efficiency and enhancing measurement confidence throughout the optical system.1.2 High-Precision Surface Control

We are capable of machining flat mirrors ranging from Φ10 mm to Φ2000 mm, featuring a clear aperture of ≥ 90% and surface accuracy of PV ≤ 1/3 λ, RMS ≤ 1/200 λ (λ = 632.8 nm). These specifications ensure that each large-aperture mirror provides a reliable optical reference with nanometer-level surface precision suitable for interferometric and high-power optical applications.1.3 Exceptional Environmental Adaptability

By employing ultra-low expansion materials such as Zerodur, ULE, and Fused Silica, our mirrors maintain dimensional and optical stability under demanding environmental conditions — including wide temperature ranges, vacuum, and mechanical load. This makes them ideal for space optics and precision laser systems.1.4 Guardian of Light Transmission

Our mirrors achieve excellent control of reflected wavefronts, minimizing phase distortion and energy loss during beam reflection, steering, or combination. This ensures high optical transmission efficiency and wavefront integrity in high-energy laser and precision interferometric systems.2. Precision Manufacturing: Ultra-Precision Machining of Planar Components

We have developed and refined a complete, deterministic process chain for manufacturing large-aperture mirrors — from material selection to final surface formation — ensuring that every step is traceable, controllable, and predictable.2.1 Deterministic Processing System

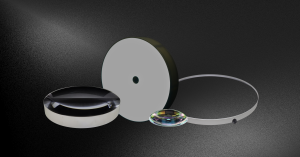

Our process integrates ultra-precision CNC grinding, computer-controlled optical surfacing (CCOS), and ion beam polishing (IBF). These technologies enable rapid convergence of surface figure accuracy to design targets while maintaining high repeatability and surface uniformity.

2.2 Material Diversity

We process a broad range of optical materials, including H-K9L, N-BK7, ULE, Fused Silica, and Zerodur. This material versatility allows us to tailor each mirror’s mechanical and thermal behavior to the application’s environmental and operational demands.3. Precise Detection: Quality Control Traceable Throughout the Process

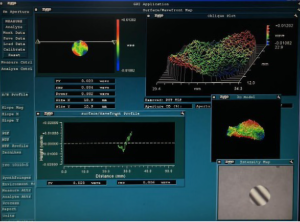

We adhere to the principle that visible accuracy is true accuracy. Our in-house inspection and metrology systems ensure that every specification is verifiable and traceable.3.1 Full-Aperture Interferometric Inspection

Using advanced laser interferometers with high-accuracy reference flats, we perform full-aperture surface testing of large-aperture mirrors. Both PV and RMS values are confirmed through dual verification — numerical data and interferometric fringe analysis — ensuring complete compliance with design specifications.3.2 Surface Quality and Roughness Control

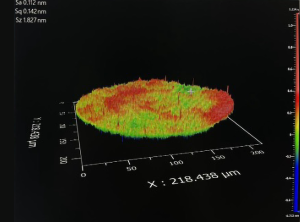

Surface defects (60/40 to 10/5) and surface roughness (≤ 0.2 nm) are strictly monitored and quantitatively recorded. White-light interferometers and high-power microscopes are used for fine-scale inspection to ensure optical smoothness and consistency.

3.3 Comprehensive Parameter Traceability

From surface figure and roughness to optical aperture and coating performance, all key parameters are recorded through systematic inspection and digital file management. Each mirror is accompanied by a full data set verifying its authenticity, reliability, and traceability.4. Core Processing Capability Indicators

Parameter Items | Technical Index |

Diameter | Ф10mm-Ф2000mm |

Clear Aperture | ≥90% |

Surface Accuracy | PV≤1/3λ,RMS≤1/200λ(λ=632.8nm) |

Surface Quality | 60/40~10/5 |

Material | H-K9L,N-BK7,ULE,Fused Silica,Zerodur,etc. |

Surface Roughness | ≤0.2nm |

5. Typical Application Areas

5.1 Optical System Detection and Calibration

In interferometers and other precision measurement systems, our mirrors provide stable reference planes for calibration of flatness, focusing, and alignment, ensuring consistent optical performance.

5.2 Astronomy and Space Exploration

Our mirrors are used in telescopes and spaceborne optical systems for beam return and system calibration, maintaining stable and clear imaging even under extreme environmental conditions.5.3 High-Energy Laser Systems

In high-energy laser platforms, these mirrors are applied for beam steering and wavefront control. Their superior surface figure accuracy and thermal stability ensure precise directionality and energy concentration of the laser output.5.4 Cutting-Edge Research and Precision Experiments

In advanced optical experiments — including quantum optics and cold-atom physics — our large-aperture flat mirrors provide high-precision planar references to ensure experimental repeatability and data reliability.6. Conclusion

Each large-aperture flat mirror we manufacture embodies the culmination of deterministic processing, ultra-precision machining, and comprehensive metrology. We recognize that every mirror underpins the performance of a major optical system.

By combining engineering excellence, rigorous testing, and full-process traceability, we deliver not only an optical component but also a reliable foundation for achieving the highest levels of optical performance.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!