Key Takeaways

- The Infinite Conjugate Microscope Objective delivers superior optical flexibility, enabling modular imaging paths through its collimated beam design.

- High numerical aperture, advanced aberration correction, and optimized working distances provide exceptional resolution and measurement accuracy. Its robust optical and mechanical engineering supports multimodal imaging, UV–IR operation, and integration with laser systems.

- These capabilities make infinite conjugate objectives essential for high-end research, semiconductor inspection, material analysis, and precision photonics applications.

Infinite Conjugate Microscope Objective: Design Principles, Imaging Performance & Advanced Applications

Achieving the ideal balance between complex optical path design, high-precision imaging, and scalable modularity is one of the greatest engineering challenges in modern optical systems. The Infinite Conjugate Microscope Objective—often referred to in industry as the infinity-corrected objective—has emerged as the cornerstone of advanced scientific instrumentation, precision inspection systems, and high-end manufacturing.

With exceptional optical flexibility, superior aberration correction, and broad compatibility with modular imaging paths, the Infinite Conjugate Objective surpasses the limitations of finite-distance systems and sets a new standard for performance, versatility, and integration capability.

This article provides a technical deep dive into the operating principles, performance foundations, optical/mechanical design strategies, and cutting-edge applications of infinite conjugate objectives.

1. Fundamentals of Optical Conjugation: Infinite vs. Finite Systems

Understanding the significance of the Infinite Conjugate Microscope Objective begins with the optical logic behind conjugation distance.

Finite-Conjugate Objectives: Fixed Design, Limited Expandability

Finite-distance optical systems form a real image at a predetermined mechanical tube length (e.g., 160 mm).

Advantages:

- compact optical architecture

- lower cost

- simpler manufacturing

Limitations:

- adding optical components alters the image plane

- poor modularity

- restricted compatibility with advanced imaging modes

This makes finite systems suitable for basic microscopes but not for high-end or customizable imaging platforms.

Infinite Conjugate Microscope Objectives: Parallel Output for Maximum Flexibility

The Infinite Conjugate Objective projects light as collimated beams, forming the image at infinity. A tube lens then focuses this parallel beam to create a real intermediate image. This architecture enables:- seamless insertion of additional modules without refocusing

- stable image plane regardless of accessory load

- integration of complex imaging systems

- filter cubes

- polarizers and waveplates

- DIC prisms

- fluorescence modules

- beam splitters

- laser coupling assemblies

Design Philosophy Comparison

Finite System |

Infinite Conjugate System |

Compact, economical |

High performance, modular |

Sensitive to insertions |

Stable with added optical elements |

Limited imaging modes |

Compatible with advanced imaging & laser applications |

2. Core Performance Pillars of Infinite Conjugate Objectives

The performance of an Infinite Conjugate Microscope Objective is determined by four interdependent factors that define resolution, accuracy, and imaging quality.2.1 Numerical Aperture (NA): Foundation of Resolution and Light Capture

The numerical aperture, NA = n · sin θ, dictates the physical limits of optical performance. High-performance infinite conjugate objectives—especially oil or water immersion types—achieve NA ≥ 1.45, enabling:- stronger light-collection efficiency

- improved fluorescence sensitivity

- visualization of nanoscale features

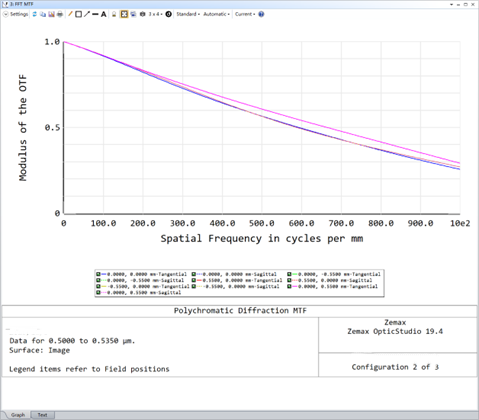

2.2 Resolution: Mapping the Limits of Optical Imaging

Within the Abbe limit (d = 0.61λ / NA), pairing high NA with short-wavelength illumination (e.g., 405 nm) yields:- lateral resolutions below 200 nm

- enhanced image sharpness

- greater detail visibility

- improved quantitative measurement fidelity

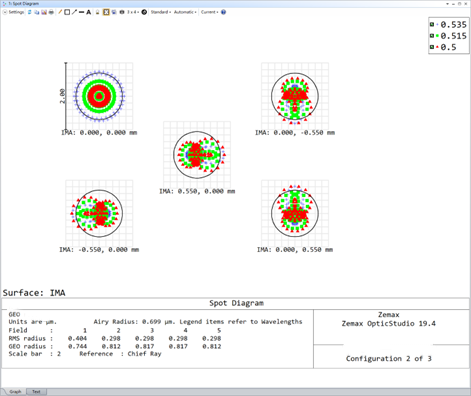

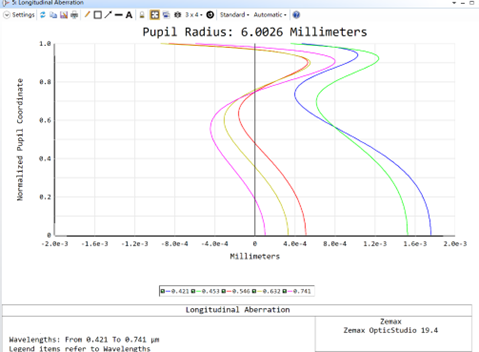

2.3 Aberration Correction: Ensuring True Image Fidelity

Infinity-corrected optical systems offer multiple aberration-correction tiers:- achromatic

- advanced apochromatic

- flat-field apochromatic (plan-apochromat)

- chromatic aberration

- spherical aberration

- coma

- field curvature

- consistent sharpness across the full field of view

- accurate multi-wavelength alignment for fluorescence imaging

- reliable stitched images for large-area analysis

2.4 Working Distance: Key to Practical Usability

The infinite conjugate design allows a wide range of working distances:- long working distance objectives for microelectronics, in vivo imaging, and MEMS inspection

- ultra-short working distance high-NA immersion objectives for highest resolution applications

3. Design Philosophy: Balancing Optical Flexibility and Precision

The Infinite Conjugate Microscope Objective is engineered around two fundamental requirements:- flexible optical path expansion

- high-precision imaging performance

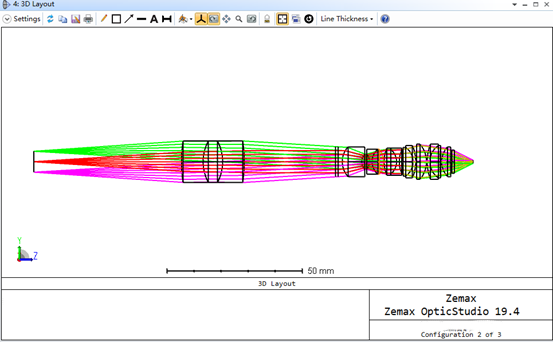

3.1 Optical Design Architecture

Low-Magnification Objectives (4×, 10×)

- 4–6 lens groups

- optimized glass combinations

- stable collimated beam output

- strong correction of basic aberrations

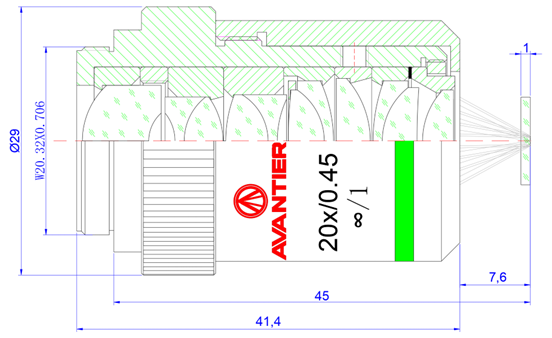

Medium-Magnification (20×, 40×)

Uses aspheric surfaces or diffractive optical elements (DOE) to:- improve optical efficiency

- reduce total lens count

- enhance edge sharpness for wide-field imaging

High-Magnification (60×, 100× Water/Oil Immersion)

These objectives demonstrate the most advanced design complexity:- refractive–reflective hybrid structures

- NA ≥ 1.4

- 8–12 precisely aligned lenses

- excellent chromatic and spherical aberration correction

Broad-Spectrum UV/IR Infinity-Corrected Designs

For applications spanning 200 nm to 15 µm, objectives use:- reflective elements

- hybrid refractive-reflective systems

- low-dispersion materials

3.2 Mechanical Design: Precision Engineering for Stability

High-performance infinite conjugate objectives require extremely tight mechanical tolerances.

Standardized Interface

- RMS or M25 threads

- micrometer-level coaxial alignment

Internal Mechanical Precision

- vibration-resistant mounting rings

- temperature-compensation structures

- fine adjustment mechanisms for axial imaging stability

Modular Expansion Capability

Systems can integrate:

- interchangeable tube lenses (modifying total magnification)

- phase contrast rings

- DIC modules

- advanced fluorescence and laser-optics modules

Compared with finite objectives, Infinite Conjugate Objectives require:

- higher machining precision

- tighter assembly tolerances

- more advanced structural stabilization

4. Application Scenarios: Enabling Modern Scientific and Industrial Innovation

The Infinite Conjugate Microscope Objective serves as a critical component across cutting-edge research fields and high-tech manufacturing.4.1 Life Sciences: Exploring the Dynamic Universe Inside Cells

Essential for:- STED, SIM, and other super-resolution modalities

- multiphoton fluorescence lifetime imaging

- real-time tracking of protein clusters

- beam modulators

- dichroic assemblies

- multi-detector fluorescence systems

4.2 Semiconductor & MEMS Manufacturing: Precision at the Nanoscale

In semiconductor alignment, defect inspection, and MEMS measurement, infinite conjugate objectives enable:- variable total magnification without losing aberration correction

- integration with laser interferometry modules

- sub-nanometer dimensional accuracy

4.3 Extended-Spectrum Imaging: From Deep UV to Far IR

Reflective and hybrid infinite conjugate designs eliminate chromatic dispersion, making them ideal for:- UV lithography inspection

- Fourier-transform infrared microscopy

- multispectral material evaluation

4.4 Laser Microfabrication and Optical Manipulation

In ultrafast laser processing, optical tweezers, and beam shaping systems:- objectives focus laser light to diffraction-limited spots

- collimated path allows flexible insertion of shaping optic

- supports precision machining, cell manipulation, and optical trapping

Epilogue

The Infinite Conjugate Microscope Objective represents the pinnacle of modern optical engineering. With its collimated optical path, exceptional aberration correction, and extensive compatibility with modular imaging systems, it forms the flexible core of high-end optical platforms. For applications requiring:- nanoscale resolution

- multimodal imaging

- optical path expandability

- precision laser manipulation

- high-stability measurement

GREAT ARTICLE!

Share this article to gain insights from your connections!