Key Takeaways

- A beam splitter cube is a key component of a Polarizing Beam Splitter, also known as a polarization beam splitter or polarized beam splitter.

- It divides a single beam of light into two beams of different linear polarizations.

- Typically configured as a cube, it avoids ghost images and ensures clean, polarized output.

- The reflected beam, termed S-polarization, and the transmitted beam, P-polarization, are produced at specific angles.

- These devices find applications in various fields, including high-powered laser systems, optical instruments, fiber optics, projectors, and precision measurement tools.

How Polarizing Beam Splitter Works

There are several types of beam splitters for many various applications in the world today, but this short read will concern itself with polarizing beam splitters.

Polarizing beam splitters, as their name implies, are a kind of beam splitter that divides a single beam of light into two beams of different linear polarizations. A polarizing beam splitter usually sees use in applications where the energy of the original input beam of light is not dissipated or absorbed.

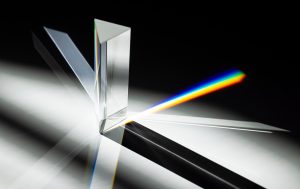

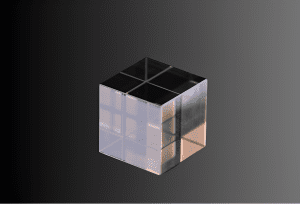

A polarization beamsplitter device’s design is often a cube as a cube configuration will offer to have only a single reflective surface. This is important because a single reflective surface will not produce ghost images. The polarized beams produced will have a cleaner, polarized output.

These types of polarized beam splitters create a translation of both the transmitted output beams that will be smaller than the original input beam. This opens opportunities for different applications regarding aligning of optical systems.

How Does a Polarizing Beam Splitter Work?

Many ask: How Does a Beam Splitter Work? What does a beam splitter do?

So here are some answers on how a polarization beam splitter works and, mainly, how it produces 2 polarized output beams.

One beam is reflected at an angle, and the other beam is let through. The reflected beam is called the S-polarization beam, while the beam that is let through is the P-polarization.

The cube design configuration is made up of two right-angle triangular prisms stacked against each other with a beam-splitting coating dividing them in between. This will make for a reflective surface that will stand 45% of the original unpolarized light beam when set properly.

There are different types of reflective coatings used in polarized beam splitters. The type of beam splitter coating dictates how polarization beam splitter works. The coating will dictate how much of the original unpolarized light is reflected and how much is let through.

Polarized beam splitter cubes feature a dielectric coating that can be intended for different uses. How much of the original light beam is let through or reflected in the s and p polarization is controlled through this coating.

Applications of Polarizing Beam Splitters

Uses and applications for polarized beam splitters range from measuring instruments to aerospace applications to DVD and CD player devices. Here is an enumeration of some of the ways we use polarizing beam splitters:

- High-powered laser applications – Polarized beam splitter cubes with large damage threshold dielectric coating can withstand high-powered laser beams.

- Cameras and optical instruments – Polarizing filters act like a Venetian blind that blocks out “messy,” glary light and lets the desirable light through for clearer imaging of objects.

- Fiber optics in isolators and fiber amplifiers– Polarizing beam splitter cubes can isolate the P-/S isolation ratios of 1/10,000 and up.

- LCOS projectors – High-resolution projectors like LCOS projectors used in home theaters, office, and school settings boast of increased contrast and overall higher image quality, and better viewing experience. This effectiveness is due to polarizing beam splitter cubes built within them.

- Blue Ray – Blue ray technology in Disc, DVD, and HD are products of the use of polarizing beam splitters.

Precision measurement and precision inspection instruments – Countless industries count on precision measurement and precision inspection tools. These industries range from the medical field to construction, surveying, etc.

FAQs on Polarizing Beam Splitters

Q: Are all beam splitters polarizing?

A: Some splitters are polarizing, while some are non-polarizing. Non-polarizing splitters split the incident beam at 2 right angles. Polarizing beam splitters split the incident beam at specific angles.

Q: What is a non-polarizing beam splitter?

A: These types of beam splitters divide the original incident beam regardless of its polarization state.

To Summarize

A polarizing beam splitter has the ability to split or divide an original incident beam of light into two linear polarizations. This ability is the reason for polarization beam splitters to be used in a broad range of real-world applications involving optics.

Industries from military, entertainment and film to the aerospace complex have been advancing from the use of polarizing beam splitters. If your industry has applications for these polarizing beam splitters, secure quality devices for lasting operations.

Contact us if you’d like to schedule a consultation or request for quote on your next project.

GREAT ARTICLE!

Share this article to gain insights from your connections!