Key Takeaways

- Optical projects often fail when designs look good in theory but fall apart in production or real-world use.

- At Avantier, we prevent these failures by ensuring designs are manufacturable, simulating real-world performance, and accounting for variations and tolerances.

- Our decades of expertise and advanced tools reduce risk, accelerate timelines, and deliver reliable optical systems for medical, aerospace, defense, life science and industrial applications.

- From concept to production, we ensure your vision translates into a product that performs and scales seamlessly.

How Our Custom Optical Design Services Prevent It

Optical systems are at the heart of many advanced products—medical imaging devices, aerospace equipment, defense technology, and scientific instruments. Yet too often, projects run into costly setbacks or fail altogether. Why? The reason is almost always the same: design decisions made early on don’t hold up in the real world.

At Avantier, we’ve spent decades helping clients avoid these pitfalls. By offering custom optical design services, we make sure projects succeed where others stumble. Here are the top three reasons optical projects fail—and how we prevent them.

1. Designs That Can’t Be Manufactured

Why projects fail:

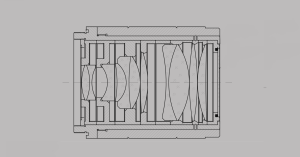

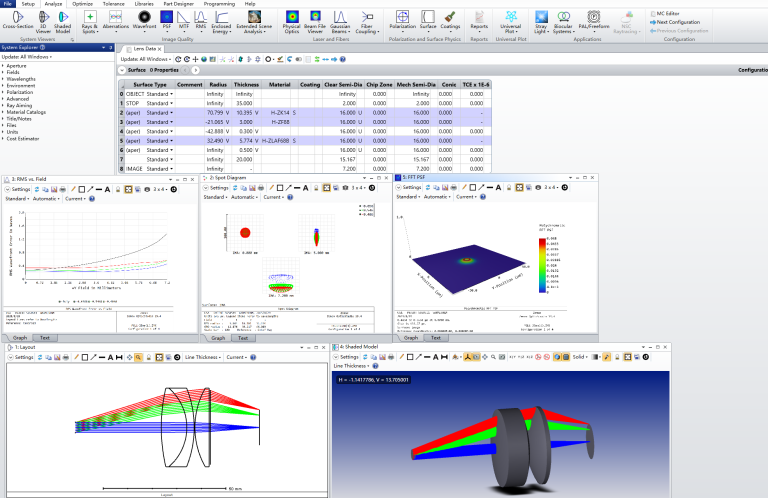

It’s one thing to make a lens design look great in simulation. It’s another to actually build it. Many designs specify materials or tolerances that are unrealistic or too expensive, causing delays and cost overruns.

How we prevent it:

Our engineers focus on manufacturable designs from day one. We consult with fabricators, apply realistic tolerances, and draw on decades of production experience to ensure that every design can move smoothly from prototype to large-scale production—without unexpected setbacks.

2. Overlooking Real-World Performance

Why projects fail:

Even if a design works “on paper,” real-world conditions introduce problems like glare, ghost images, or loss of contrast. Ignoring these system-level effects can compromise the final product.

How we prevent it:

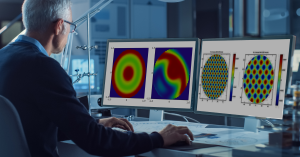

We simulate how the optical system will behave in its actual environment—factoring in coatings, housing, apertures, and more. This proactive approach means fewer surprises during testing and a reliable system that performs exactly as intended.

3. Ignoring Variations and Tolerances

Why projects fail:

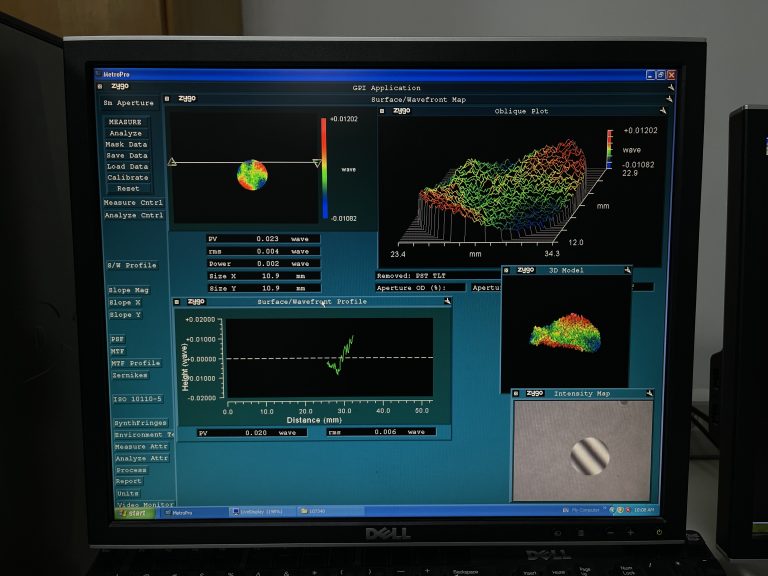

No part is ever manufactured to perfection. Small shifts during production or assembly can throw a sensitive design off balance. Without planning for tolerances, a product may work in theory but fail in reality.

How we prevent it:

We analyze how small deviations impact performance, then design systems that remain robust under real-world conditions. This helps clients avoid costly redesigns and ensures consistency across both prototypes and scaled production.

Why Partner with Avantier?

When clients search for custom optical design services, they’re looking for a partner who can reduce risk, shorten timelines, and deliver a solution that actually works in practice. That’s what we do at Avantier.- We provide tailored optical systems for aerospace, biomedical, life sciences, quantum computing, and other advanced technology sectors.

- We support projects from rapid prototyping through volume production.

- We build more than lenses—our capabilities include aspheres, mirrors, windows, prisms, and complex optical assemblies.

- Our state-of-the-art quality control ensures every component exceeds industry standards.

Bringing Your Vision to Reality

Optical projects fail when designs don’t translate into reliable products. At Avantier, we bridge that gap. With a full suite of optical engineering consulting and custom design services, we partner with you to create systems that perform, scale, and stand the test of time.

Whether you’re developing a new medical imaging device, an aerospace instrument, or a defense system, our team is ready to help. Contact us today to discuss your project or request a quote—we’d love to turn your idea into a successful reality.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!