Key Takeaways:

Freeform optics are custom-designed optical components with irregular surfaces for precise light manipulation. Unlike traditional, symmetrical lenses, freeform optics offer unique benefits:

- Compactness and weight reduction: By combining multiple elements into one, freeform optics enable miniaturized devices.

- Enhanced performance: They effectively correct aberrations for sharper focus, wider fields of view, and improved image quality.

- Tailored functionality: Freeform optics design can be for specific applications, like creating non-standard image distortion or precise illumination patterns.

What Are Freeform Optics?

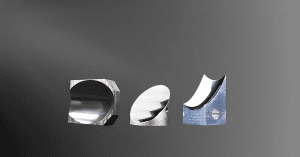

Freeform optics are optical components with non-rotationally symmetric and often complex surfaces. These parts are designed to precisely manipulate light rays in desired ways. Freeform surfaces can be tailored to meet specific requirements. For instance, they can reduce optical aberrations, improve imaging performance, and make any optical system lightweight and compact. They can also increase illumination efficiency.

Advantages of Freeform Optics

Optical components with shapes that are not bound by rotational symmetry and support higher order curves and localized profiles offer unique design challenges.

- Compact and lightweight: using freeform surfaces allows designers to combine several optical elements into single components, in turn, reducing the number of optical elements ideally for device miniaturization.

- Improved optical performance: Freeform lenses can correct aberrations more effectively than conventional lenses, leading to improved image quality, larger depth of field, expanded field of view, and sharper focus.

- Customized functionality: The flexibility of freeform lens design allows for the creation of lenses or mirrors tailored to specific applications, such as non-standard image distortion or complex illumination pattern, controlled light distribution / reduced light pollution.

- Adding alignment features: These alignment features facilitate surface measurements during manufacturing and freeform alignment/mounting during system integration.

Freeform Optical Manufacturing

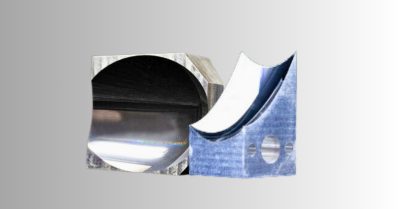

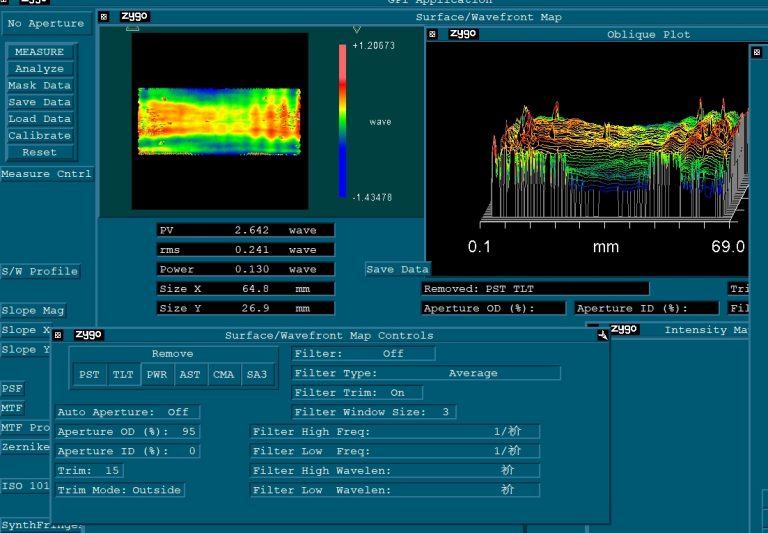

It is challenging to fabricate freeform optics compared to traditional optics. Manufacturers often use precision machining or advanced manufacturing techniques to produce these complex optical surfaces. Examples include diamond turning, precision molding, precision 3D printing, and computer-controlled grinding and polishing. Even when molding is involved, subtractive manufacturing processes often create the initial mold template first.

Avantier uses advanced CNC machining and grinding/polishing techniques to produce various freeform optical components. These include lenses, mirrors, and prisms. Avantier has decades of experience in precision molding of lenses and supports high-volume applications in precision-molded freeform optics.

We provide comprehensive support throughout the entire optical journey. This includes design, manufacturing, and rigorous testing of optical components and systems. Our team is ready to work closely with you on your custom project, whether you require standard spherical and aspherical elements, components with aspherical surfaces, or freeform optics.

GREAT ARTICLE!

Share this article to gain insights from your connections!