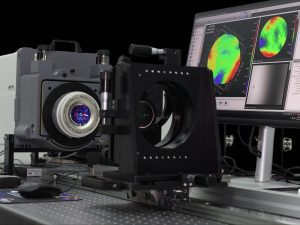

Introduction to SSI Subaperture Stitching Interferometry

In the evolving landscape of optical systems manufacturing, test results with high measurement accuracy are critical—especially for large aperture and aspherical surface components used in technologies such as astronomical telescopes and EUV lithography. Conventional interferometers struggle to capture precise full aperture measurements due to limitations in range and aberration correction. This is where Subaperture Stitching Interferometry (SSI) revolutionizes the field, offering a “block measurement-global reconstruction” method that ensures λ/10 precision (λ = 633 nm). SSI has become a go-to method for tests of large and complex optical components that feature rotational symmetry or freeform geometries.

Core Principles and Technical Advantages

Breaking Through Range Limits

SSI enables precision testing of large optics—such as the parabolic mirror or aspherical elements in space telescopes—by dividing the target into smaller, manageable subapertures. A compact interferometer scans these sections individually. A stitching algorithm, relying on overlapping regions (minimum overlap: ≥¼ subaperture), reassembles the entire full aperture profile with high fidelity. This principle of “measuring the big with the small” allows accurate evaluation of optics at the system level.Mitigating Measurement Errors

By minimizing interferometer-induced measurement errors like tilt, shift, and translation, SSI ensures measurement accuracy at λ/10 (PV) for 633 nm wavelength, critical for achieving reliable test results in high-precision applications.Preserving High-Frequency Data

Unlike traditional full-aperture tests that often blur fine features, SSI retains high-frequency surface information, which is essential in applications requiring extreme surface uniformity.Key Measurement Processes

- Subaperture Division

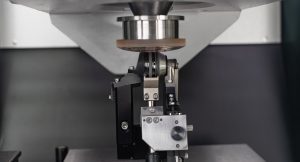

The surface is divided into zones based on aperture size, geometry (e.g., rotational symmetry or freeform), and overlap criteria. - Scanning Strategy

The interferometer or test part moves along X/Y axes to cover each zone, allowing subaperture stitching across the full field. - Translation and Rotation

For optics with non-circular symmetry, translations and rotations help optimize coverage while reducing mechanical stroke demands. - Stitching Algorithm

Least squares optimization and global alignment algorithms fuse phase data, minimizing errors introduced during scanning.

Breakthroughs and Remaining Challenges

Testing Aspherical and Freeform Surfaces

Testing a test aspherical or parabolic mirror often uses spherical wavefront references. SSI methods can achieve deviations as low as 0.064λ PV post-stitching. For freeform optics, advanced subdivision and optimization algorithms ensure accurate surface reconstruction.Managing Installation and Algorithmic Errors

SSI must address measurement errors such as alignment drift, defocus, and fifth-order coma. Adaptive calibration and correction optics (e.g., image field curvature mirrors) are used to compensate for these effects and ensure accurate test results.Industrial Implementation and Equipment

Equipment Suppliers

QED Technologies leads the industry as the sole supplier of commercial stitching interferometry systems. Their ASI (Q) platform is widely adopted for tests of large, non-spherical surfaces.Notable Applications

- James Webb Space Telescope (JWST): SSI verified nanometer-level polishing across its segmented parabolic mirror, achieving 0.8 nm RMS surface error and curvature radius deviation under λ/50⁵.

- Large Ground-Based Telescopes: Facilities like Keck and VLT depend on SSI for precision optical component alignment and full-aperture verification.

The Future of Subaperture Stitching Interferometry

Multimodal Data Integration

Next-gen SSI systems will fuse phase-shifting interferometry (PSI) with multi-frame intensity capture to refine phase data and enhance spatial resolution.Intelligent Automation

Emerging AI-driven path planning and measurement error correction will optimize subaperture stitching sequences. Innovations like dynamic interference using wavelength modulation will further increase measurement robustness.Conclusion

Subaperture stitching interferometry has redefined how we perform high-precision testing on large aperture and aspherical surface optical components. By combining sophisticated algorithms, modular scanning, and intelligent calibration, SSI provides unmatched test results even on the most challenging optical systems. As it integrates AI and hybrid sensing methods, SSI will continue to lead the future of precision optical testing.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!