Key Takeaways

- Stress-free objective lenses offer superior imaging precision by eliminating internal stress, preventing distortion, and ensuring true image restoration.

- Their design accounts for thermal expansion, reducing errors in varying environments.

- Key applications include polarized light microscopy, scientific research, medical diagnostics, and industrial testing.

- Advanced manufacturing processes, including precise material selection and assembly, ensure the stability and accuracy of these lenses.

- Avantier’s custom stress-free objective lenses provide cutting-edge optical solutions, making them essential for high-precision fields.

In the continuous evolution of optical technology, stress-free objective lenses have emerged as a leading solution, particularly for advanced polarized light microscopy. These lenses are designed to prevent signal distortion caused by stress during lens assembly, offering unique advantages for high-quality imaging. This article delves into the characteristics, principles, production processes, and applications of stress-free objective lenses, with a focus on their role in enhancing polarized microscopy.

Features of a stress-free objective lenses

The most notable feature of stress-free objective lenses is their excellent imaging stability and accuracy. By eliminating internal stress, these lenses effectively avoid imaging distortion and ensure accurate image restoration. Additionally, the design focuses on matching the thermal expansion coefficient of the materials, reducing imaging errors caused by temperature changes and enhancing the lens’s adaptability to various environments.

In advanced polarized light microscopy, stress-free objectives play a critical role in preventing distortion of polarized light interference signals caused by stress within the lens material. This stress, often introduced during lens assembly and curing, can interfere with the accuracy of detecting the crystallographic axis of crystal samples, as seen through a Boernet microscope. By using stress-free lenses, manufacturers ensure that optical performance remains stable, preserving measurement accuracy. While essential for high-end polarizing microscopes, stress-free optics limited applications in other areas where standard lenses suffice.

The principle of stress-free objective lenses

The design principle of stress-free objective lenses involves eliminating internal stress generated during manufacturing and assembly. This stress may arise from inhomogeneous lens materials, adhesive curing pressure, or mechanical assembly. By optimizing material selection, improving bonding processes, and using precision assembly equipment, stress-free lenses operate without external force influences, enabling accurate imaging in a stress-free state.

The manufacturing process of the stress-free objective lenses

The manufacturing process for stress-free objective lenses is complex and delicate. From material selection to processing, bonding, assembly, and inspection, every step must be strictly controlled. During lens bonding and assembly, advanced automated equipment and precise measuring tools are essential to maintain the lens’s stress-free state and imaging performance. Additionally, annealing is a key step in eliminating internal stress.

- Lenses material selection: When choosing lens materials, choose unstressed, birefringent materials.

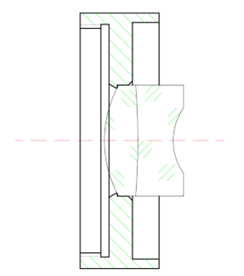

- Lens structure: As shown in the figure below, the lens is fixed to the holder with the unstressed glue, and the holder should also be designed in the shape of a “worker”, so that when the holder is assembled, the extrusion stress on the holder will not be transmitted to the lens.

Assembly without stress

When the lens is assembled, the lens pressure ring and the pressure cap should be gently tightened, and then the low-stress glue to fix the pressure ring and the pressure cap on the mirror body.

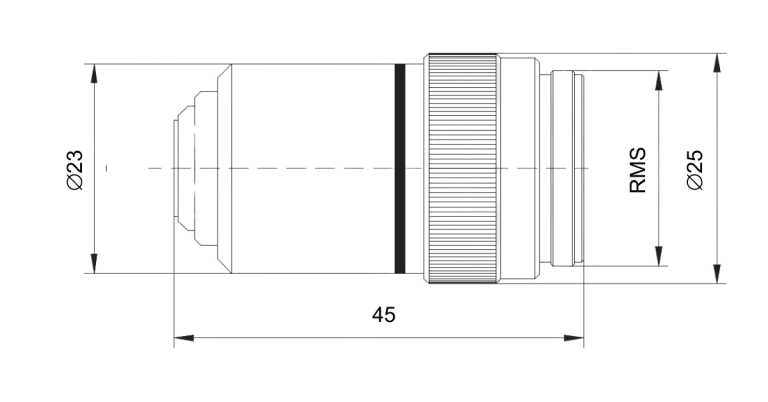

The following image is an example assembled as a normal microscope objective lens.

Applications of stress-free objective lenses

These lenses are widely used in fields requiring high-precision imaging, such as scientific research, medical treatment, and industrial testing. In scientific research, stress-free objective lenses provide scientists with accurate observation data. In the medical field, they enhance clarity for doctors observing internal structures, supporting diagnosis and treatment. In industrial testing, stress-free lenses are the preferred tool for detecting precision parts and materials due to their stability and accuracy.

In conclusion, stress-free objective lenses play a vital role in modern optical technology, offering unique advantages. As science and technology continue to advance, and application demands increase, stress-free objective lenses will undoubtedly play an even greater role across various fields.

Custom stress-free objective lenses by Avantier

Our stress-free lenses represent a groundbreaking advancement in optical technology, offering unparalleled imaging precision and stability. Their innovative design and meticulous manufacturing process ensure the elimination of internal stress, making them a reliable choice for high-demand applications in research, medicine, and industrial testing. As the pursuit of superior imaging continues, stress-free objective lenses are set to lead the future of optical solutions. Ready to experience this innovation firsthand? Contact us today to learn more about how Avantier’s stress-free objective lens can elevate your optical systems.

GREAT ARTICLE!

Share this article to gain insights from your connections!