Key Takeaways:

- C-Lens production requires high-quality micro lenses with excellent surface quality and cost-effective methods.

- Precise machining is essential for achieving the required dimensions and surface quality of microscale lenses.

- Material selection balances refractive index, dispersion, and chemical resistance for optimal optical performance.

- Efficient manufacturing processes ensure consistent quality and cost-effectiveness in mass production.

Project Overview : Microscale C-Lens Manufacturing Challenges

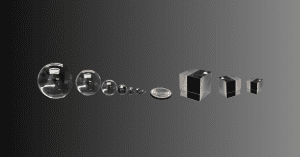

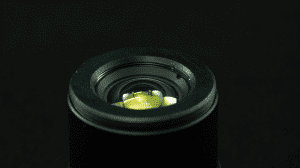

Manufacturing C-Lenses at the microscale presents challenges in: precision machining, material selection for optical properties and durability, surface quality control, moisture/corrosion resistance, and cost-effective mass production. Meticulous attention to each aspect is required to consistently achieve high-quality lenses.

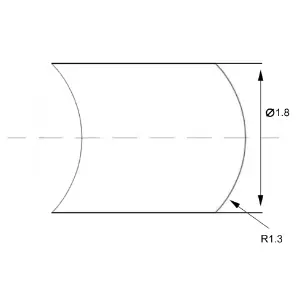

Lens specification:

Material | H-ZF5 |

Radius | 1.3mm |

Diameter | 1.8mm |

Surface Quality | 40-20 |

Manufacturing Challenges and Solutions

Microscale Manufacturing:

- C-Lenses have diameters around 1mm, requiring highly precise machining techniques for production

- Microfabrication and precise control ensure lenses meet required dimensions and surface quality.

Material Selection:

- Materials (e.g., BK7, N-SF11, SF11, silicon) must balance refractive index, dispersion, thermal expansion, and chemical resistance.

- Stability and optical performance are critical factors.

Surface Quality and Optical Performance:

- Control surface shape, cleanliness, and roughness during manufacturing.

- Precisely manage refractive index distribution for optimal optical performance.

Cost-Effective Mass Production:

- Efficient production processes are essential for consistent, cost-effective manufacturing.

- Each lens must meet specifications.

Conclusion

These C-lenses and D-lenses epitomize cutting-edge solutions tailored for a wide array of fiber optics applications. With distinct advantages such as cost-effectiveness, minimal insertion loss, and a broad operational distance range, these lenses offer superior performance compared to other gradient-index lenses. Despite the inherent challenges in manufacturing micro lenses, including precise machining techniques and material selection considerations, Avantier has successfully assisted the customer and navigated these obstacles to deliver high-quality products. Leveraging over a decade of expertise in lean micro-lens production, we ensure that each lens meets stringent specifications while maintaining cost-effective mass production. With our commitment to innovation and quality, Avantier continues to be a trusted partner in the field of micro-optics.

GREAT ARTICLE!

Share this article to gain insights from your connections!