Case Study: Athermalization Design Using Chalcogenide Glass in LWIR Infrared Lenses

Overview

As the demand for infrared imaging grows across defense, industrial, and smart applications, the challenge of maintaining stable imaging performance across temperature ranges becomes more critical. This case study by Avantier showcases how chalcogenide glass, a promising infrared optical material, was used to develop an athermalized infrared lens for a long-wave infrared (LWIR) thermal camera.

The Challenge of Designing an Athermal Infrared Lens

Traditional infrared lenses rely on crystal materials like germanium or zinc selenide. While effective, they are costly, difficult to machine, and prone to performance shifts due to temperature changes. For next-gen thermal cameras—especially those used outdoors or in rugged environments—maintaining image clarity across wide temperature ranges is a must. This demands an athermalization design approach.

Why Chalcogenide Glass?

Chalcogenide glass offers high transmission in the 8–12 µm range, low thermal expansion (~10–20×10⁻⁶/°C), and is suitable for precision glass molding. Unlike crystals, it allows for cost-effective mass production and flexible processing. Its low dn/dT makes it ideal for optical passive athermalization, minimizing focus shifts due to temperature fluctuations.

Optical Design Highlights

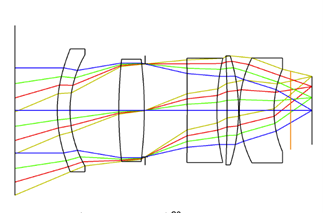

- Application: LWIR camera lens

- Wavelength: 8–12 µm

- Effective Focal Length: 20 mm

- F/#: 1.0

- Sensor: 1024×768 @ 12 µm pitch

- Design: 5-lens system with 1 aspheric surface, all using chalcogenide glass

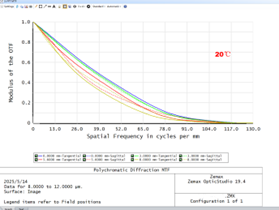

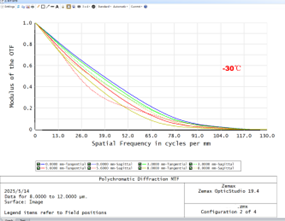

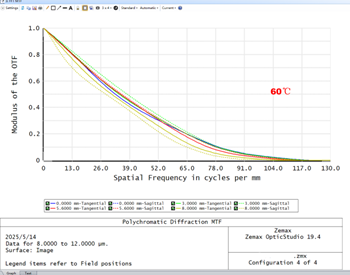

The lens demonstrated stable imaging performance across -30°C to 60°C. Simulated MTF showed minimal degradation, achieving >30% contrast at 40 lp/mm—even under temperature variations. This proves the system meets high-resolution imaging needs without requiring active thermal compensation.

Extended Use: Infrared Windows

In parallel, infrared windows made from chalcogenide glass were implemented to protect the optics without compromising transmission. To enhance durability, a DLC (diamond-like carbon) hard coating was applied, boosting chemical resistance and lifespan in harsh environments.

Results

- Cost-effective solution using molded chalcogenide glass

- Stable optical performance over wide temperature ranges

- Flexible production: Suitable for both prototyping and volume manufacturing

- Durable infrared windows for rugged deployment

Concluding Athermal Infrared Lens Design

This project highlights the value of chalcogenide glass as a next-gen infrared optical material. With superior thermal stability, moldability, and performance in LWIR, it supports compact, reliable, and scalable solutions in modern thermal camera systems and infrared lens assemblies. Contact us today for your next athermalization project.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!