Key Takeaways

- Aspheric bonded lenses minimize chromatic and spherical aberration through advanced manufacturing techniques, enhancing the performance of aspherized achromatic lenses.

- High-transmittance glasses were used to meet stringent requirements for medical retinal detection.

- The production process involves complex design, precise material selection, and challenging bonding steps.

- Multi-stage polishing and rigorous quality control ensure optimal optical performance and lens reliability.

Advanced Design and Applications of Achromatic Lenses

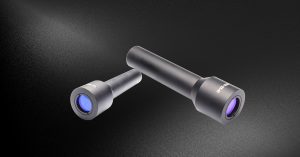

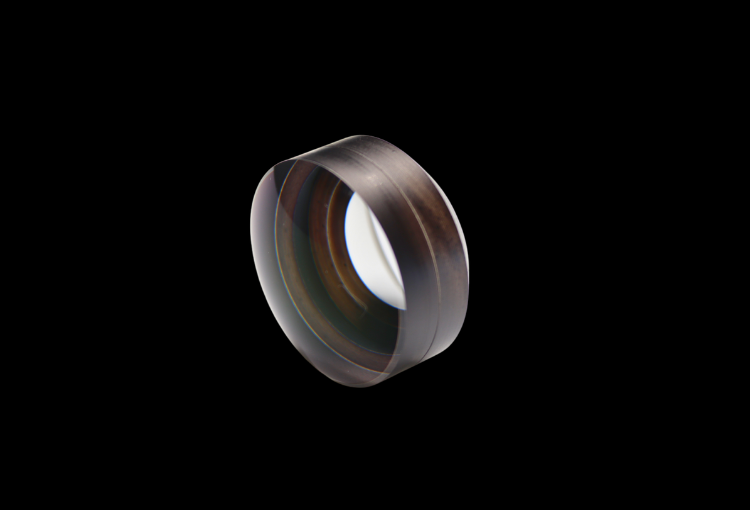

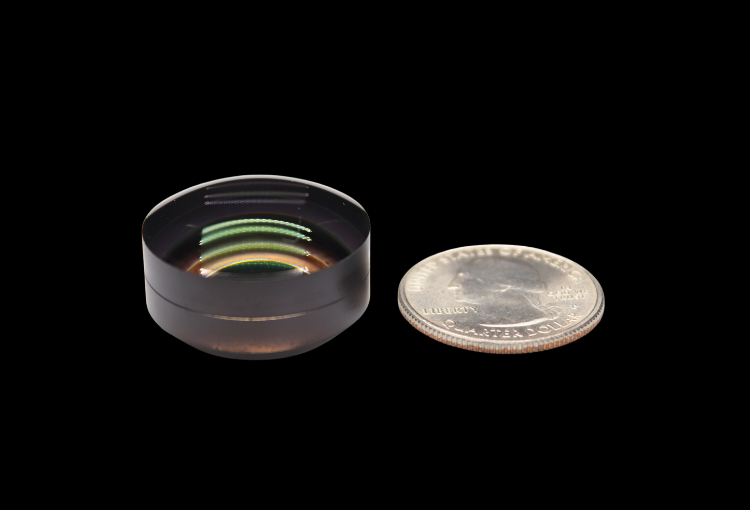

Achromatic lenses are employed to reduce, or even eliminate, chromatic aberration, and their design also aids in minimizing spherical aberrations. These lenses are well-suited for various applications, including fluorescence microscopy, image relay, inspection, and spectroscopy. Typically created either by cementing two elements together or by housing them together, an achromatic lens produces smaller spot sizes compared to equivalent singlet lenses.

- Distinctive and innovative design, cost-effective, color-corrected aspheric lens

- Superior color correction compared to conventional achromatic lenses

- Comparable spherical aberration correction to precision-machined aspheric lenses

Project Overview

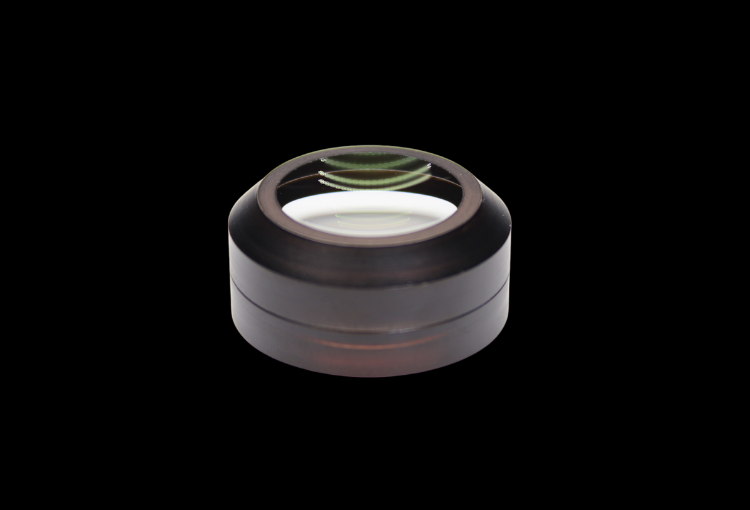

This project was conducted in the medical field for detecting the human retina. Typically, an achromatic lens is composed of two optical components which are glued together, usually a positive low refractive index (glass) element and a negative high refractive index (quartz glass) element. Since the customer’s requirement for the transmittance of a single lens was very high in this project, we used H-ZF & H-LAK high-transmittance glass. To meet the customer’s specific application needs in the medical field, we have carried out special treatments during the processing and polishing to meet the customer’s requirements.

Production and Polishing

Achromatic aspheric bonded lenses, as highly complex optical components, involve multiple technical challenges and unique steps, making them a critical piece in the manufacturing industry. The continuous advancement of optical technology has propelled them to the forefront of lens design and manufacturing.

1. Complexity of Design

The design of aspheric lenses must consider not only basic spherical aberrations, astigmatism, and chromatic aberrations but also the need for precise control over various optical distortions. For achromatic lenses, the design requirements are even more stringent, necessitating optimization of optical performance while accommodating different materials, curvatures, and shapes.

2. Material Selection

Selecting suitable optical materials is crucial for aspheric bonded lenses. The refractive indices and dispersion properties of different materials must be precisely matched to minimize chromatic aberrations. Additionally, considering stability and processability during the manufacturing process adds another layer of complexity to material selection.

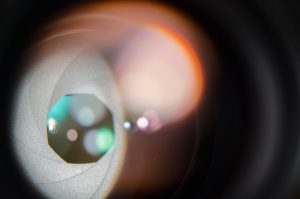

3. Challenges in the Bonding Process

Bonding is a critical step in the production of aspheric bonded lenses and presents a technical challenge. Ensuring a uniform and bubble-free bond between two or more elements is paramount. This step requires a high degree of precision and control to ensure the structural integrity and optical performance of the lens.

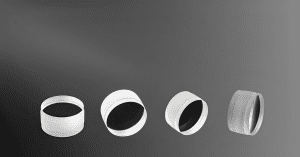

4. Multi-stage Polishing Process

Polishing is a key step in lens manufacturing, and the complex shape of aspheric bonded lenses makes the polishing process particularly intricate. From rough polishing to precision polishing, high levels of craftsmanship and advanced polishing equipment are required. The surface accuracy of the lens directly influences its final optical performance, necessitating precise control at every stage.

5. Challenges in Coating Processes

The application of coatings is a crucial step in enhancing lens performance, especially when with regards to chromatic aberrations. Ensuring the uniformity and consistency of coatings is essential for the prevention of optical distortions. This demands strict coating processes and high-quality coating materials.

6. Necessity of Quality Control

Due to the complexity of the manufacturing process, quality control is paramount. High-precision measurement and detection equipment are indispensable to verify whether the lens conforms to design specifications, ensuring the stability and reliability of its optical performance.

Summary of Aspherized Achromatic Lens

Crafted from high-transparency glass, these lenses exhibit distinctive design, cost-effectiveness, and superior color correction compared to conventional achromatic lenses. This project encompasses intricate procedures, including material selection, bonding challenges, multi-stage polishing, coating processes, and rigorous quality control. This sophisticated manufacturing process tackles the complexities of designing and producing aspherized achromatic lenses, which underscores their crucial role in the advancement of optical technology for medical diagnostics and other precision applications.