Key Takeaways

- Micro prisms are crafted with precision to handle specific wavelengths and are available with various coatings for tailored performance in any optical system.

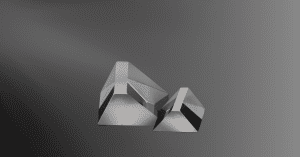

- Avantier offers penta prisms for consistent 90-degree light deviation and right-angle prisms for 90 or 180-degree deviations.

- Our micro prisms undergo precise cutting, grinding, polishing, and coating processes to ensure optimal quality.

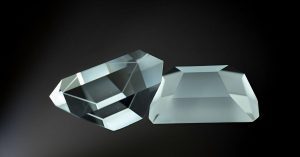

- We provide a wide range of custom optical prisms, including Amici, corner cube, and UV fused silica prisms, for diverse optical systems.

Advancing Optical Technology with Custom Micro Prisms

The micro prisms, so small that they are invisible to the naked eye, play a crucial role in the development of our society, including information communication.

These micro prisms significantly contribute to the miniaturization and lightweighting of optical equipment used in various industries.

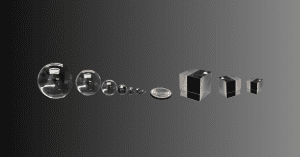

Avantier’s micro prisms are customized to precision using prism glass, tailored to meet the specifications desired by our customers. They can bend light according to required conditions, transmitting or reflecting specific wavelengths. Our technology customizes ultra-small prisms with diameters of less than 3 mm to suit various environments and conditions, facilitating the realization of our customers’ projects.”

The production process of micro prisms is crucial for their performance, with design and manufacturing playing key roles. Typically, micro prisms are crafted by cutting and grinding optical glass, followed by precise polishing to meet specific standards. They are then coated externally and inspected for any defects. At Avantier, we offer two types of micro prisms: coated or uncoated, depending on the customer’s requirements.

Penta micro prisms are shaped like a pentagon, featuring seven faces and ensuring a stable light deviation of 90 degrees, regardless of the entry point of light. These prisms are made using various substrate materials such as BK7 Grade-A optical glass, Corning Fused Silica 7980, JGS1, and JGS2.

On the other hand, right-angle micro prisms take the form of a right triangle, with two parallel triangular faces and three rectangular faces. Depending on which face the light enters initially, these prisms can deviate light by either 90 degrees or 180 degrees. Our right-angle micro prisms have a bevel ranging from 0.1 to 0.2 mm.

Different coatings, such as anti-reflection (AR) coatings and bandpass filters, can be added to the surface of these prisms. They can also be used as beam splitters.

Despite their different shapes, these prisms share common physical properties like reflectivity, surface quality, and working wavelength. Avantier can create custom micro prisms using a variety of materials and coatings, including those tailored for different UV, visible, and IR wavelengths upon request.

Manufacturing Equipments

- KERN EVO CNC Machining Center

- Precision Optics Polishing with Satisloh SPS-200

- Precision Lens Cutting with Sidai SPCM-M1

- Precision Diamond Turning with Nanotech 250 UPL

Metrology

- Zygo Interferometers

- TriOptics MTF Test Stations/Optical System Testing

- TriOptics OptiCentric 100 Dual

- Agilent Cary 7000 Spectrophotometer

- Shimadzu UV3600 Spectrophotometer

- LUPHOScan 420

- NewView 9000 3D Optical Surface Profiler

- Leitz PPM Gold

Avantier specializes in offering customized optical prisms, including Amici Prism, Right Angle Prisms, Penta Prisms, Half Penta Prism, Light Pipes and Homogenizing Rods, UV Fused Silica Right-Angle Prism, Micro Prism, Corner Cube Prism, Dove Prism, Custom Cemented Prism, Polygon-Shaped Prism, Precision Penta Prism.

Reach out to us with your specific requirements, and our team of experienced optical manufacturing engineers will collaborate closely with you to ensure that we deliver optical prisms tailored to your system’s requirements while staying within your budgetary constraints.

GREAT ARTICLE!

Share this article to gain insights from your connections!