Key Takeaways:

- Laser-Induced Damage Threshold (LIDT) defines the laser energy or power at which materials sustain permanent damage.

- It varies with laser type—pulsed or continuous—and is influenced by factors like pulse duration, wavelength, material defects, and thermal properties.

- Pulsed lasers often cause non-thermal damage via ionization, while CW lasers primarily induce thermal effects. Testing methods include single-pulse (1-on-1) and multi-pulse (S-on-1) protocols.

- Accurate LIDT data ensures system safety, guides material selection, and supports performance optimization in applications like micromachining, optics, and laser-based technologies.

I. Laser-Induced Damage Threshold: Concept, Mechanism, and Technical Importance

1. Definition of Laser-Induced Damage Threshold (LIDT)

Laser-Induced Damage Threshold (LIDT) is formally defined as the minimum laser energy density (J/cm² for pulsed lasers) or power density (W/cm² for continuous-wave lasers) at which permanent and irreversible damage—such as melting, ablation, cracking, or coating delamination—occurs on or within an optical element under specific laser irradiation conditions. These conditions include wavelength, pulse duration, repetition rate, beam spot size, and irradiation duration. LIDT is a critical quantitative measure of a material’s resistance to laser-induced damage.

1.1 Core Damage Mechanisms

Thermal Damage: Laser energy absorbed by the material is converted into heat, resulting in a sharp local temperature rise. This is especially relevant for CW or high-repetition-rate lasers, where heat accumulation can cause melting, thermal stress cracking, decomposition, thermal lensing, or even thermal explosion. Key material parameters include melting point, thermal conductivity, and thermal expansion coefficient.

Field-Induced (Electric Breakdown) Damage: Predominantly observed under ultrashort-pulse lasers (picosecond or femtosecond), where high peak power generates strong electric fields. These fields disrupt atomic/molecular bonds via multiphoton and avalanche ionization, creating plasma and causing ablation. This is a non-thermal process, with sharply defined damage edges.

Defect-Initiated Damage: Microscopic defects (impurities, microcracks, voids, dislocations, coating imperfections) act as local hot spots or field enhancement zones. These defects significantly lower the actual LIDT compared to theoretical values.

Shock Wave Damage: Intense pulsed lasers can induce rapid ablation or plasma expansion, generating shock waves that propagate through the material and potentially cause internal delamination or fracture, even at points distant from the laser spot.

1.2 Technical Importance of LIDT

System Safety and Reliability: Knowing the LIDT is essential for designing safe laser systems, selecting compatible optics, and setting safe operational parameters. This prevents catastrophic failure or safety hazards due to optical damage.

Performance and Cost Optimization: By understanding LIDT constraints, engineers can select components that strike a balance between safety margins and system performance. This supports optimized component selection at a competitive cost.

Materials and Process R&D: LIDT serves as a benchmark for evaluating new optical materials, coatings (e.g., laser-resistant films), fabrication methods, and post-processing treatments, such as ion-beam polishing.

II. Laser Modes: Differences Between Pulsed and Continuous Lasers

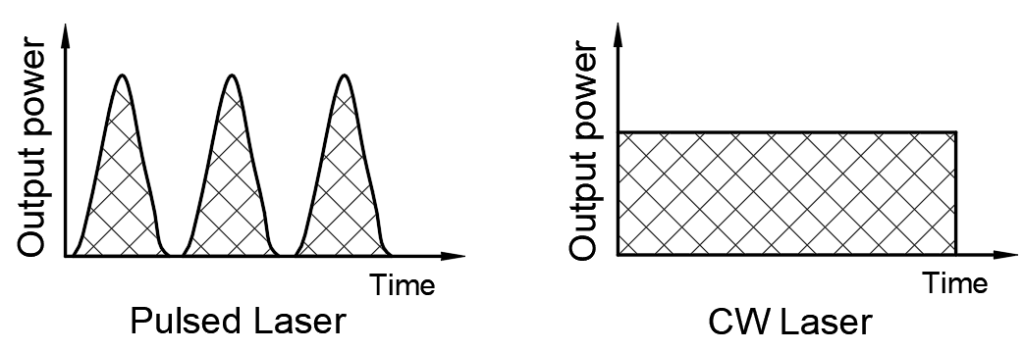

Laser temporal characteristics fundamentally influence damage mechanisms and LIDT definitions.

2.1 Pulsed Lasers

Characteristics: Energy is delivered in short bursts, with extremely high peak power (pulse energy / pulse width). Pulses may be regular (e.g., Q-switched, mode-locked) or irregular.

Pulse Width Range: Milliseconds (ms) to attoseconds (as)

Damage Mechanisms:

- Nanosecond pulses and longer: Thermal and field effects both contribute to damage. Visible effects include pits and spatter.

- Ultrashort pulses (ps, fs): Nonlinear ionization dominates, with minimal heat-affected zones, enabling “cold” material processing. Damage thresholds are expressed in fluence (J/cm²).

Measurement Focus: Fluence for single-shot thresholds; average power density for high-repetition operation.

Applications: Laser micromachining, ophthalmic surgery, laser fusion, laser marking/cutting.

2.2 Continuous-Wave (CW) Lasers

Characteristics: Continuous or slowly modulated power delivery.

Dominant Mechanism: Thermal accumulation. Material damage results from exceeding critical temperature thresholds (melting, softening, stress-induced cracking). Typical damage includes large-area melting or foaming.

Measurement Focus: Power density (W/cm²) and maximum permissible exposure time.

Applications: Laser communications, displays, heat treatment, medical surgery.

Key Distinction: Pulsed lasers cause damage via transient peak power; CW lasers via sustained heating. This distinction determines testing methods and threshold definitions.

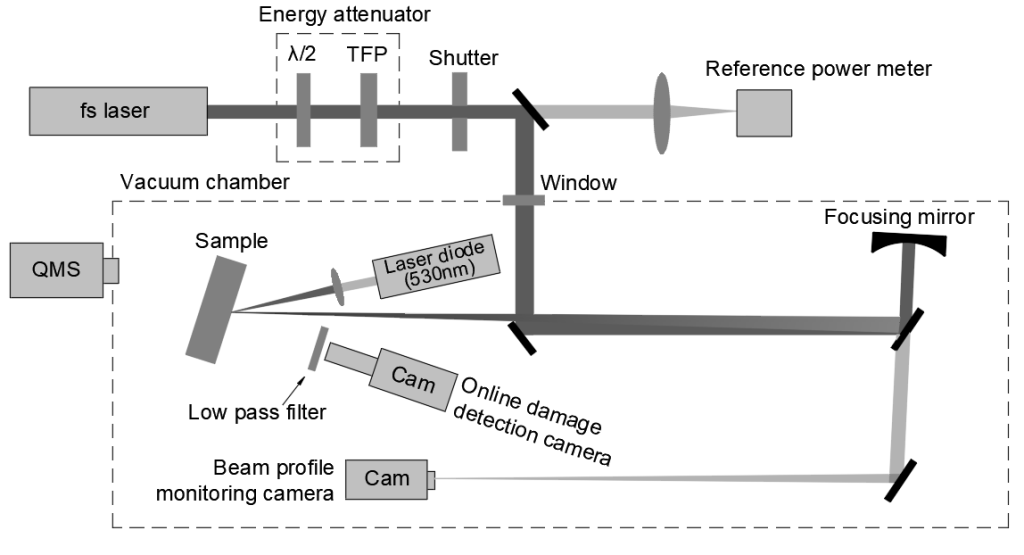

III. Core LIDT Testing Methodologies

3.1 Single-Pulse Testing (1-on-1)

Principle: One laser pulse is applied per site across many sample sites. Fluence is varied to statistically determine the damage threshold.

Advantages:

- Clear concept and strong repeatability.

- Eliminates pulse accumulation effects.

- Standardized under ISO 21254-1.

Limitations:

- Time-intensive.

- Does not account for cumulative effects.

Use Cases: Benchmarking material resistance, evaluating low-repetition or single-shot systems (e.g., fusion, laser weapons).

3.2 Multi-Pulse Testing (S-on-1)

Principle: A single site is irradiated with multiple pulses (10³–10⁶) to assess damage accumulation.

Advantages:

- Simulates real-world laser exposure.

- Quantifies cumulative damage.

- Standardized under ISO 21254-2.

Limitations:

- Requires long test durations.

- Sensitive to pulse count and frequency.

Use Cases: Evaluating optics for high-repetition lasers (LIDAR, fiber lasers), studying long-term material performance.

IV. Key Influencing Factors and Testing Considerations

4.1 Laser Parameters

- Wavelength (λ): Affects material absorption.

- Pulse Width (τ): Impacts diffusion time and ionization likelihood.

- Spot Size and Profile: Determines energy density and peak intensity location.

- Repetition Rate (f): Drives heat accumulation in multi-pulse tests.

- Polarization and Incidence Angle: Affects electric field distribution and absorption.

4.2 Material and Component Characteristics

- Absorption Coefficient: High absorption leads to thermal damage.

- Defect Profile: Surface and bulk defects significantly lower LIDT.

- Thermophysical Properties: Thermal conductivity, expansion, and melting point.

- Coating and Design: Multilayer coatings, design wavelengths, and field enhancement layers.

- Surface Quality: Smoothness affects scattering and localized field intensity.

4.3 Environmental Conditions

- Atmosphere: Vacuum vs. air can affect cooling and damage mechanisms.

- Temperature: Substrate temperature alters material response.

Contaminants: Dust, vapor, and oil films can lower thresholds.

V. Challenges and Future Trends in LIDT

5.1 Current Challenges

- Statistical Dispersion: LIDT data inherently varies due to material imperfections (Weibull statistics).

- Detection Sensitivity: Difficult to detect nanoscale damage precursors.

- Ultrafast Laser Complexity: Nonlinear effects make theoretical modeling difficult.

- Low Testing Throughput: Traditional tests are slow for new material screening.

- Limited Simulation of Extreme Conditions: Lab tests may not replicate real-world environments.

5.2 Future Directions

- In-Situ, High-Sensitivity Detection: Real-time photothermal and photoacoustic monitoring.

- Multiphysics Simulations: Coupled modeling of optics, thermodynamics, and mechanics.

- Machine Learning for LIDT Prediction: Automated defect classification and threshold estimation.

- Online Monitoring and Lifetime Prediction: Integrating LIDT sensors for predictive maintenance.

Advanced Materials and Structures: Nanostructured coatings, wide-bandgap materials, and innovative surface treatments.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!