Key Takeaways:

- We offer precision lens transmittance testing using light intensity ratio and integrating sphere methods.

- These techniques ensure high optical performance, verifying brightness, color accuracy, and system efficiency across application-specific wavelengths.

- Our lab-built setups deliver reliable results for coated, curved, or multi-element lenses.

- While we don’t use high-speed laser transmittance meters, our capabilities meet demanding standards in automotive, machine vision, and scientific optics — all backed by meticulous quality control and expert engineering.

At Avantier, we understand that the optical performance of a lens goes beyond shape and alignment — transmittance through the lens is critical to system efficiency, image quality, and application-specific performance. That’s why we’ve invested in professional-grade transmittance testing methods to verify that each lens meets rigorous optical transmission standards.

What Is Lens Transmittance Testing?

Transmittance measures how much light passes through a lens — calculated as a percentage of the incoming light that successfully exits the lens. This simple number plays a big role in image clarity, brightness, and color accuracy. Especially in high-precision applications such as machine vision, LIDAR, or infrared imaging, poor transmittance can compromise the entire optical system.

Our Testing Capabilities

We offer two highly reliable testing methods to measure lens transmittance:

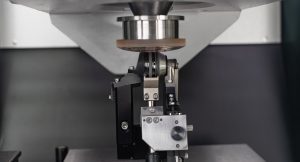

1. Light Intensity Ratio Method

This method calculates transmittance by comparing laser light intensity before and after passing through the lens:

T = I / I₀ × 100%

- ✅ Advantages: Low-cost, fast, ideal for lab-based single-point checks

- ⚠️ Limitations: Sensitive to stray light and beam divergence

- ✅ Requirement: Highly stable laser source (intensity fluctuation <1%)

This setup is manually assembled by our experienced engineers, ensuring flexibility and customization across different wavelength bands.

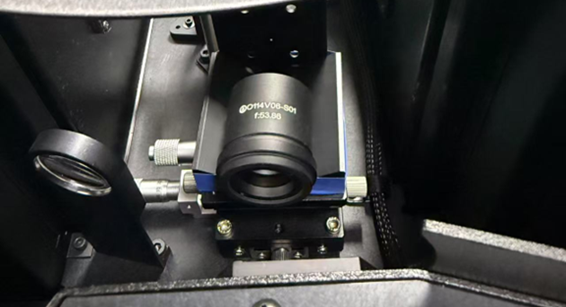

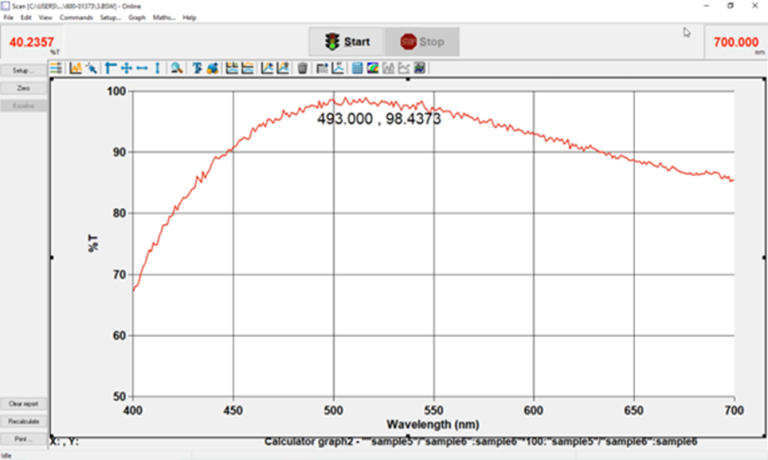

2. Integrating Sphere Method

For lenses with coatings or complex geometries, we use a spectrophotometer-integrating sphere system to collect both transmitted and scattered light, eliminating error from surface reflection and scattering.

- ✅ Repeatability: Up to ±0.2% accuracy

- ✅ Best For: AR-coated lenses, curved lenses, multi-element assemblies

- ✅ Example Equipment: XP-T-2000 system (380–1100 nm)

This method offers robust, repeatable measurements in both R&D and production verification contexts.

Why Transmittance Testing Matters

- Imaging Performance

- Brightness & Detail: Higher transmittance improves light delivery to sensors, vital for low-light environments such as surveillance or automotive night vision.

- Color Fidelity: Inconsistent transmittance across wavelengths can distort color. Quality coatings ensure color accuracy and consistency.

- Optical System Efficiency

- Energy Loss Prevention: Each uncoated lens surface reflects ~4% of light. With AR coatings, this drops below 0.5%, pushing system transmittance above 97%.

- Application-Specific Bands: Transmittance must be optimized for the working wavelength — such as 850 nm for NIR industrial imaging, or 1064 nm for LIDAR lenses.

Use Cases & Industry Standards

Our testing supports a variety of industries and optical product lines, including:

- Automotive LIDAR Optics: Lenses tested for 1064 nm band transmittance >95%, even after thermal cycling (-40 °C to 85 °C).

- Machine Vision Production Lines: Integrated into CCD line scan inspection systems with sub-second testing times per lens.

- Scientific Instruments: Full-spectrum verification using UV-VIS-NIR spectrophotometry.

Important Testing Considerations

- Laser Source Stability: For pulsed lasers, we use synchronized triggering; for continuous lasers, temperature control prevents power drift.

- Sample Preparation: Fingerprints can lower transmittance by 5–10%. All lenses are thoroughly cleaned before testing.

- Coating-Wavelength Matching: For accurate results, the test laser must match the lens’s optimized wavelength range — e.g., SWIR coatings for 900–1700 nm.

Looking Ahead: Evolving with Metasurface Optics

As Metalens (metasurface lens) technology advances, traditional testing methods must adapt to nanoscale structures and sub-wavelength optical responses. Future transmittance analysis will require enhanced spatial resolution and expanded detection ranges — a challenge we’re already preparing to meet.

Why It Matters to You

At Avantier, transmittance testing is not a checkbox — it’s a quality guarantee. Whether you’re developing high-end imaging systems, advanced sensors, or cutting-edge photonics, our attention to optical detail ensures that your lens performs exactly as specified.

Contact us today to learn how our lens verification processes can support your next optical project.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!