Key Takeaways:

- Miniaturized optics for small satellites are enabling high-resolution imaging, agile beam steering, and real-time spectral sensing in compact CubeSat optical payloads.

- Innovations in miniaturized satellite optics—including compact satellite telescopes, MEMS mirrors, and CubeSat spectrometers—deliver advanced performance within strict mass, volume, and power limits.

- Engineers overcome challenges such as vibration, thermal shifts, and radiation by using lightweight mirrors for satellites, athermal designs, additive manufacturing, and space-qualified optical components.

- Modern small satellite imaging systems now achieve powerful mission capabilities once limited to large spacecraft, making Earth observation and scientific missions more scalable, affordable, and data-rich than ever.

Miniaturized Optics for Small Satellites & CubeSats

Compact, Flight-Qualified Optical Systems for Next-Gen Payloads

Miniaturized optics are redefining how space engineers design CubeSats and compact satellites. These advanced optical payloads enable high-resolution imaging, agile beam steering, and real-time spectral analysis—all within tight 1U–6U constraints.

At Avantier, we engineer flight-qualified optical assemblies—from diffraction mirrors to compact spectrometers—built to withstand vibration, thermal shifts, and radiation exposure while delivering exceptional on-orbit performance.

What Are Miniaturized Optics for Small Satellites?

Miniaturized optics are compact, lightweight optical systems engineered to fit within the tight mass, volume, and power constraints of CubeSats and small satellites. These systems enable high-resolution imaging, beam steering, and spectral sensing in space-limited payloads, allowing small spacecraft to perform missions once reserved for large satellites.

Benefits of Miniaturized Optics for CubeSats

- Lower mass – Reduces structural loads and enables smaller launch vehicles

- Lower power – Extends mission life and supports energy-restricted platforms

- High-resolution imaging – Achieves meter-class ground sampling from compact telescopes

- Agile beam steering – MEMS mirrors enable rapid, precise pointing

- Real-time spectral sensing – Compact spectrometers enable environmental and chemical analysis

- Lower launch cost – Smaller payloads reduce both manufacturing and launch expenses

Compact Satellite Telescopes: Big Vision in Small Form

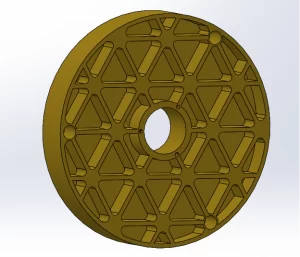

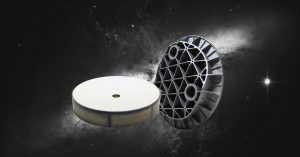

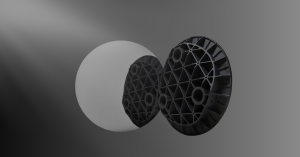

Modern CubeSat telescopes—typically housed in 3U to 6U platforms—use folded optical designs to achieve large focal lengths within minimal space.

Technical Highlights

- Aperture: 60–100 mm

- Effective focal length: 300–1000 mm

- Optical design: Ritchey–Chrétien or off-axis reflective (no chromatic aberration)

- Stray light control: Deployable baffles and precision baffling

Performance: Ground resolution of 5–10 m/pixel from 500 km orbit.

Compatibility: Customizable for CMOS or CCD sensors.

Engineering Challenges & Solutions

Challenge | Avantier Solution |

Launch vibration | Precision optical alignment with isostatic mounts |

Thermal variation | Athermalized mirror assemblies |

Weight constraints | Additive-manufactured titanium or CFRP structures |

MEMS Diffraction Mirrors: Agile Beam Steering for Space

MEMS mirrors offer rapid beam control and precision pointing in a miniature footprint—ideal for compact satellite systems and laser-based payloads.

Capabilities

- Tip/tilt range: ±5° to ±30°

- Bandwidth: >1 kHz

- Mirror coatings: Silver (VIS–NIR), gold (SWIR)

Advantages for Payload Engineers

- Enables real-time target tracking and adaptive optics correction

- Eliminates bulky moving linkages → higher reliability, lower mass

- Radiation-tolerant packaging ensures long-term orbital stability

Engineering Innovations

- Fabricated via SOI wafer processing and deep reactive ion etching (DRIE)

- Protected with SiO₂ overcoats and hermetic glass-frit bonding

Compact Spectrometers: Unlocking On-Orbit Spectral Intelligence

Miniature diffraction-based spectrometers provide real-time chemical and environmental analysis from orbit—critical for Earth observation and resource mapping. Core Technologies- Diffraction grating or Fabry–Pérot Interferometer (FPI)

- Spectral resolution: 10–20 nm (VNIR/SWIR)

- Mass: <500 g

- Power draw: <5 W

- Gas and mineral detection

- Precision vegetation and water monitoring

- Material characterization in situ

- Nanoimprint lithography for precision grating replication

- Direct bonding on silicon benches

- Integrated micro-optics and thermoelectric stabilization

System-Level Integration: Engineering for Reliability

Constraint |

Engineering Response |

Volume |

Folded optics, deployable components |

Thermal control |

Passive athermal materials, heaters |

Vibration |

Damped optical mounts, shock isolation |

Power |

MEMS-based passive beam steering |

Radiation |

Rad-hard coatings and optical shields |

Driving the Future of Compact Optical Payloads

Miniaturized optics have transformed CubeSats into powerful observation platforms. The integration of precision diffraction mirrors, MEMS beam steering, and spectral imaging continues to expand mission capabilities—at a fraction of traditional size and cost.

Avantier’s expertise in custom optical systems, lightweight mirror design, and space-qualified manufacturing enables engineers to push the limits of compact satellite performance.

🚀 Need a custom optical payload or diffraction mirror for your compact satellite?

Contact Avantier’s optical engineering team to discuss flight-qualified designs for your next CubeSat or micro-satellite mission.

Frequently Asked Questions

- What is a diffraction mirror?

A diffraction mirror is a reflective optical element that uses a microstructured surface—such as a grating or metasurface—to precisely control the phase and direction of light. This allows engineers to perform beam steering, spectral separation, and wavefront correction in compact systems. In small satellites, diffraction mirrors reduce size and mass while maintaining optical precision. - How do CubeSat optics work in compact payloads?

CubeSat optics rely on folded reflective designs, such as off-axis or Ritchey–Chrétien configurations, to achieve long focal lengths within tight volume constraints. MEMS mirrors enable agile beam steering and jitter correction, while miniaturized spectrometers capture spectral data for imaging and environmental sensing—all within a few watts of power. - What are the advantages of miniaturized optics for compact satellites?

Miniaturized optics reduce mass, power consumption, and volume while delivering high-resolution imagery and spectral data. They enable 5–10 meter per pixel imaging from 500 km orbits, rapid beam steering with MEMS mirrors, and on-orbit spectral analysis—capabilities once reserved for large satellites. - Which materials and coatings are preferred for satellite optical lenses and mirrors?

Engineers often use aluminum or silicon carbide mirrors with diamond-turned surfaces for lightweight rigidity. Coatings like silver or gold enhance reflectivity across visible and shortwave infrared bands, while SiO₂ overcoats protect against oxidation. Athermal mounts made of titanium or carbon-fiber composites help maintain optical alignment through thermal changes.

- What is a diffraction mirror?

GREAT ARTICLE!

Share this article to gain insights from your connections!