Key Takeaways

- Athermal optical systems leverage sophisticated athermalization techniques, advanced materials like ALLVAR Alloy 30, and precise designs to maintain performance under temperature changes.

- These systems are essential in infrared imaging, space optics, and telecommunications.

- Innovations such as passive athermalization and uncooled detectors enhance their versatility.

- Despite material constraints and design challenges, athermal optical systems deliver reliable, cost-effective solutions for precision applications.

What are Athermal Optical Systems?

Athermal optical systems are a cornerstone of modern optics, designed to ensure consistent optical performance across varying temperatures. These systems are indispensable in environments where precision and reliability are non-negotiable.

Principles of Athermalization

Athermalization involves a combination of optical, mechanical, and material strategies to counteract the effects of temperature changes on optical systems. The key principles include:

Material Selection

Choosing the right materials is fundamental to passive athermalization.

- Optical Materials: Glasses with low thermal expansion and complementary dn/dT values help counteract temperature effects.

- Housing Materials: Innovative materials like ALLVAR Alloy 30, with a negative CTE, expand design possibilities.

Optical Design Strategies

Careful optical design ensures temperature stability without compromising performance.

- Achrothermic Systems: Dual optimization for achromatic and athermal properties enhances system stability.

- Wavefront Aberration Theory: Designs are refined to minimize aberrations caused by temperature changes.

Mechanical Design Techniques

Mechanical adjustments play a critical role in maintaining stability.

- Passive Athermalization: Design housing components to compensate for thermal expansion of optical elements.

- Bimetallic Housings: Combining materials with different thermal properties achieves optimal results.

Mathematical Modeling

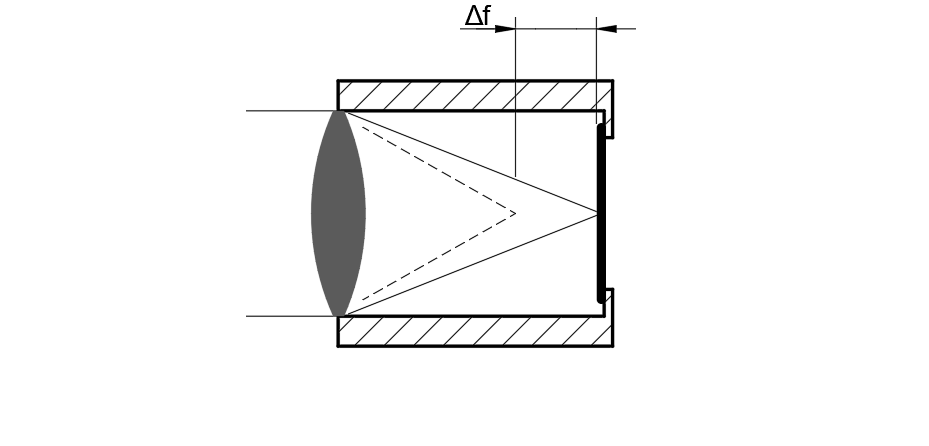

Precise equations and modeling ensure accurate compensation for thermal effects.

- Thermal ν-number and CTD can be used to calculate and correct focal shifts due to temperature variations.

Index Matching

Synchronizing refractive index changes and thermal expansion ensures seamless performance. This technique enhances reliability but can add design complexity.

Advantages of Athermal Systems

Athermal systems excel in maintaining performance across extreme temperature ranges. But the benefits of athermal systems extend beyond temperature stability. Other advantages you are likely to see include:- Reliability: With fewer active components, athermal systems are robust and require less maintenance.

- Cost-Effectiveness: Passive designs eliminate the need for energy-intensive thermal controls, making them ideal for challenging environments.

Limitations

Despite their advantages, athermal systems face inherent challenges that demand innovative solutions.- Design Complexity: Developing athermal systems requires advanced techniques and extended timelines.

- Performance Trade-offs: Prioritizing thermal stability may impact other optical properties.

- Environmental Sensitivity: While effective against temperature changes, these systems can still be influenced by factors like humidity or pressure.

Applications

The versatility of athermal optical systems makes them indispensable across diverse industries.- Infrared Imaging: Essential in thermal cameras, where maintaining focus is critical for security and surveillance.

- Space Optics: Power-efficient and reliable, they are well suited to the extreme conditions of space exploration.

- Industrial Monitoring: Their robustness ensures consistent performance in high-temperature environments, such as furnaces and chemical plants.

- Telecommunications: Athermal designs enhance fiber coupling efficiency, something that is critical for WDM systems.

Recent Developments

Continuous innovation is expanding the horizons of athermal optical systems.- Expanded Materials: Research into materials with a negative coefficient of thermal expansion, such as ALLVAR Alloy 30, is broadening possibilities for athermal optical designs.

- Passive Athermalization: Collaboration between industry leaders has improved the performance of commercially available optical doublets.

- Technological Integration: Advances in uncooled detectors and wafer-scale manufacturing enhance the accessibility and affordability of athermal systems.

Design Challenges and Solutions

Designing athermal systems such as infrared optics requires overcoming significant technical obstacles, including material and thermal limitations.- Material Limitations: The need for unique thermal properties, combined with optical requirements, narrows available options.

- Thermal Defocus: Addressing focal shifts due to temperature requires precision modeling.

- Solutions:

- Advanced materials and glass maps optimize design for both lens and housing.

- Integrated optical-thermal analysis anticipates potential misalignments and thermal effects.

- Techniques like wavefront aberration optimization enable consistent performance across varying temperatures.

The Future of Athermal Optical Systems

Athermal optical systems are at the forefront of research in optical designs, as we discover new and better ways to deliver stability and reliability in diverse and challenging environments. As innovation in materials and design continues, these systems are poised to play a pivotal role in advancing industries like space exploration, telecommunications, and industrial monitoring. Their ability to adapt and perform under extreme conditions makes them an invaluable asset in modern optics. Contact us on your athermal optics project.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!