Key Takeaways:

- Avantier specializes in premium medical optics, collaborating with clients for tailored solutions.

- Optics are pivotal in modern medicine, driving diagnostic breakthroughs and treatment advancements.

- High-quality optics are essential for applications like endoscopy, OCT, PCR, robotic surgery, and ophthalmology.

- Manufacturing precision is crucial, balancing quality, cost, and timeline under stringent regulatory standards.

- Avantier exemplifies cost-efficient production, swift customization, adherence to performance standards, and regulatory compliance.

Avantier, a distinguished manufacturer of high-precision medical optics, collaborates with clients to produce cutting-edge optical components and devices tailored to their precise specifications. This scientific reading material explores the pivotal role of optics in modern medicine, delves into the intricate process of manufacturing optics, presents exemplary applications, and emphasizes the critical factors of cost, timeline, performance, and regulatory standards.

Medical Optics in Modern Medicine

Optics plays a paramount role in contemporary medical advancements, serving as the cornerstone of diagnostic breakthroughs. Medical optics, comprising a range of optical technologies, finds extensive utilization in medical research, diagnostics, and treatment. Avantier proudly manufactures top-tier optical components for medical devices and offers custom solutions to cater to diverse medical needs.

Applications of High-Quality Medical Optics

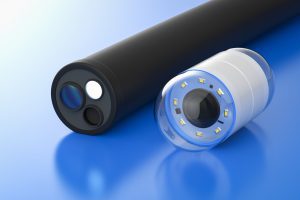

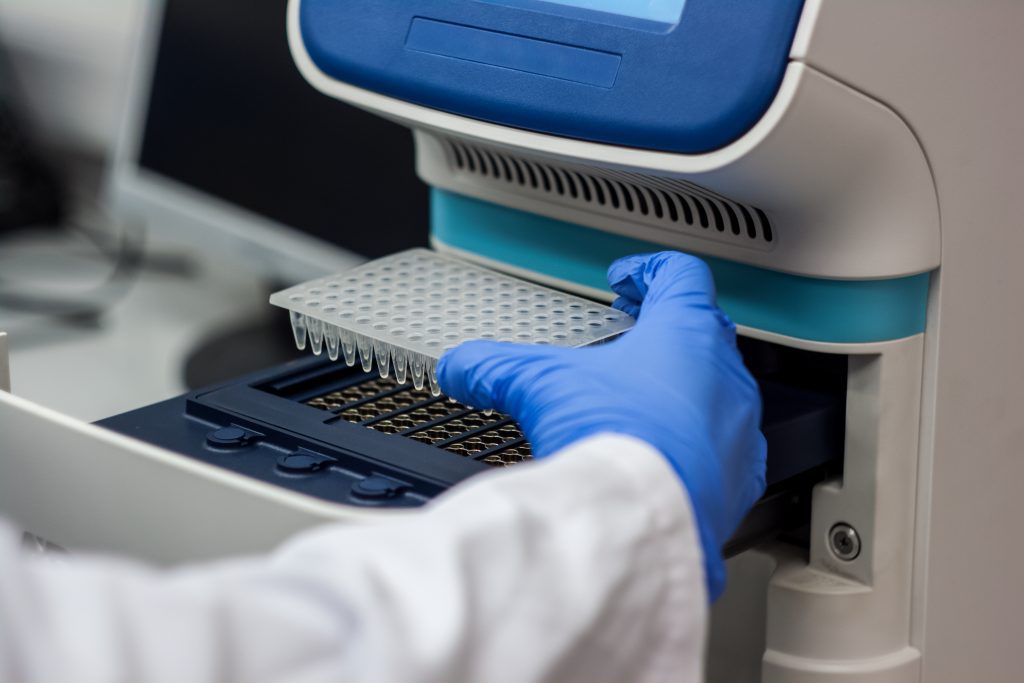

High-performance optics underpin medical advancements across various domains, including research, diagnostics, and treatment. Medical professionals benefit from advanced techniques facilitated by robust optical components. These optics feature prominently in applications such as micro endoscopy, optical coherence tomography (OCT), polymerase chain reaction (PCR) instruments, robotic surgery, and laser-based ophthalmology.

Manufacturing Precision Medical Optics

Manufacturing optics for medical devices demands an unwavering commitment to quality. The precision of optical components is of utmost importance, as human lives rely on their flawless operation within diagnostic and treatment protocols. Stringent standards govern the production of medical optics, balancing the imperative of superior quality with budget and time constraints. Effective medical optics design harmonizes these factors to deliver high-performance optics at a competitive price with rapid turnaround.

Exemplary Medical Optics Applications

Avantier exemplifies the creation of medical optics meeting the highest standards within budget and time constraints. A notable application is optical coherence tomography, a noninvasive diagnostic technique offering cross-sectional retinal imaging. This aids in the diagnosis and treatment of conditions like macular degeneration and diabetic eye disease. Furthermore, laser-assisted eye surgery, supported by advanced medical optics, has supplanted traditional cataract surgery. Optical coherence tomography assists in mapping the eye’s structures before precise laser interventions for improved patient outcomes.

Cost Considerations

The sensitivity to cost within medical services necessitates an approach that optimizes benefit-cost ratios. Avantier ensures cost-efficient production of medical device optics through comprehensive design and engineering expertise.

Timeline and Performance

The development of medical devices and research endeavors operates under strict time constraints. Avantier offers a broad range of readily available optical components for medical devices and specializes in swift customization. Our design and engineering team collaborates with clients to expedite product development plans while maintaining exceptional performance standards. High-performance optics and lens assemblies for medical use are indispensable for reliable laboratory and clinical applications, preventing equipment failures that could obscure research findings or lead to catastrophic clinical outcomes.

Quality Standards

Medical optics adhere to stringent regulatory standards to ensure device reliability. Avantier holds ISO 13485 certification, signifying our ability to consistently produce high-quality optics in medical use compliant with customer requirements and regulatory mandates. State-of-the-art metrology equipment guarantees that our medical optical components conform to all relevant standards, facilitating their seamless integration into medical research, diagnostic, and treatment applications. Custom validation processes are available to further ensure quality and compliance.

In conclusion, the collaboration between Avantier underscores the pivotal role of precision medical optical components in advancing the field of medicine. The commitment to quality, cost efficiency, timeline adherence, and regulatory compliance positions these manufacturers at the forefront of medical optics innovation, ultimately benefiting both patients and the scientific community.

GREAT ARTICLE!

Share this article to gain insights from your connections!