Key Takeaways

- Edge blackening, using blackening paint, reduces stray light and enhances imaging by absorbing unwanted reflections.

- Applied after coating and before assembly, it is typically used on non-optical surfaces.

- Blackening methods range from manual to fully automated, balancing precision and flexibility.

- Key challenges—adhesion, thickness uniformity, and whitening—can be mitigated through proper blackening paint selection, surface preparation, and curing.

- As automation advances, improved blackening techniques will further enhance optical component quality for precision applications.

Edge Blackening

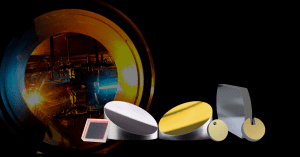

Lens edge blackening is an auxiliary part of optical component processing. It is generally done after coating and gluing and before lens assembly. The optical element is blackened with black paint, giving the surface of the element a black appearance that both improves the aesthetic appearance and absorbs and blocks unwanted light.

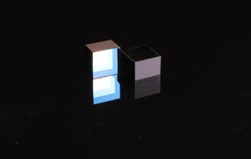

Lens edge blackening can be done on an optical surface, such as for systems where the aperture of the light has a precision requirement. For instance, a specific sized area of the surface of a prism or lens can be coated to avoid the entry of light beyond the aperture into the system. More often, edge blackening acts on optical components, especially on the non-optical surface of the lens, to reduce the influence of stray light and improve the imaging quality of the optical system.

Stray light refers to unwanted light pollution, the unintended light transmitted to the sensor in an optical system. There are many causes of stray light, such as the reflection of light on the surface of the structural part, the entrance of the light source outside the field of view into the system, the secondary reflection of the surface of the optical element, and so on. Various measures are taken during the production of the lens to eliminate as much stray light as possible, and one of these is blackening the non-working face of the optical element. The non-working surface of the optical element is an important source of stray light. Blackening a non-optical surface can reduce the scattering of unexpected light and also absorb the reflected light from the lens barrel and the stop. Therefore, edge blackening is an important part of optical component processing.

Processing Step

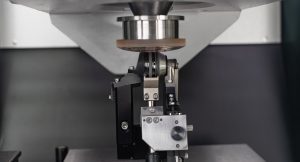

Traditional edge blackening is a manual operation, but due to the popularity of automation, conventional optical components can also be fully automated. Fully automatic inking equipment can precisely control the thickness and uniformity of the inking, providing high production efficiency but poor flexibility. At present, semi-automatic or manual work is usually used for special optical components and small batch production.- Preparation: The appropriate ink type and ratio should be selected for specific product requirements, and the ink should be used as soon as possible after completion. At the same time, before blackening, clean the lens to ensure the cleanliness of the blackening area.

- Blackening: A semi-automatic blackening device can fix the lens by vacuum suction, and manual blackening can be accomplished with an ink pen once dipped during the operation of the turntable. For some lenses with more complex shapes and smaller sizes, completely manual Blackening is used, a process that requires more skill and experience. In addition, there are spraying methods of operation. Before spraying, tape is used to protect the surface of the lens that does not need to be inked, spray with a spray gun, and dry after ink jet.

- Curing: During curing the blacked component is baked in the oven. Different types of optical components should be cured at different temperatures and times, and the curing agent in the ink needs to fully react to ensure the firmness and strength of the ink layer.

Common problems and improvement measures

- Adhesion of ink layer

During blackening the ink layer needs to combine well with the optical element, and adhesion of the ink layer is an important performance index of edge blackening. One commonly used adhesion test method is the cross-cut test. The test involves using a grid tool to evenly draw a certain number of squares in a designated size on the ink layer. After the grid is completed, the tape is used to test whether the ink layer is falling off, and its adhesion can be judged according to the amount and area of the peeled ink layer.

Poor adhesion of the ink layer is generally related to the control of the inking process. An abnormal proportion of the curing agent might lead to poor adhesion, as would insufficient curing temperature or time. The cleanliness of the area to be inked also affects the adhesion of the ink layer.

- Thickness and uniformity of the ink layer

When processing optical components, it is necessary to control the size of the components after blackening. Improper blackening can cause abnormalities in the final size of the product, such as poor uniformity or overall thickness that exceeds the standard. Size overshoot will affect the assembly of the lens, while poor uniformity will affect the concentricity of the optical system. These issues are usually caused by problems in the ratio of ink used or in blackening techniques.

- Ink layer is whitish

The purpose of blackening is to reduce the influence of stray light, and any whitening of the ink layer will affect the inhibition effect of stray light. When applying ink on a ground surface, any roughness will affect the penetration of the ink layer and may produce white spots. When the blackening area is not clean the penetration of the ink will also be hampered, resulting in a whitish ink layer.

The Importance of Edge Blackening in Precision Optics

Edge optical blackening is a crucial step in optical component processing, significantly reducing stray light and enhancing imaging performance. By carefully selecting blackening methods—whether manual, semi-automatic, or fully automated—manufacturers can optimize ink adhesion, thickness, uniformity, and overall quality. Addressing common challenges, such as poor adhesion, uneven coating, or whitening of the ink layer ensures the effectiveness of the blackening process. As automation technology advances, improvements in the precision and efficiency of blackening will further enhance the performance of optical systems across various applications.

Related content

GREAT ARTICLE!

Share this article to gain insights from your connections!