Key Takeaways

- The wavefront error in parabolic mirror telescopes directly affects image quality. Through advanced manufacturing methods, the optimization of these mirrors ensures superior image clarity.

- Parabolic mirrors in telescopes offer a distinct advantage in image quality optimization. Merging traditional and computer-guided correction methods achieves peak performance.

- Manufacturing methods of parabolic mirrors significantly impact image quality in telescopes. Integrating traditional and computer-guided techniques ensures optimal imaging performance.

Optimizing Image Quality Through Parabolic Mirrors in Astronomical Telescopes

The astronomical telescope, a quintessential tool for exploring the cosmos, operates as an imaging device of paramount significance. Central to its performance is the quality of its imaging, a metric profoundly influenced by its primary component – the mirror. The pivotal criterion by which imaging quality is gauged is the relative image intensity, commonly known as the Strehl ratio. In this discourse, the central focus is on elucidating the strategies that underscore the improvement of image quality through the optimization of parabolic mirrors.

Wavefront Error and Image Intensity:

A fundamental parameter influencing image quality is the wavefront error of the mirror. For instance, a mirror with a wavefront error equivalent to 1/10 of a wave engenders a relative image intensity of 67%. This wavefront error magnifies due to the dual passage of the surface error during reflection. This revelation underscores the intricate interplay between mirror imperfections and image quality.

Striving for Optimal Quality:

A pivotal threshold of image quality rests upon a mirror’s wavefront error of 1/16 wave rms. This measurement culminates in a relative image intensity of 86%, an established benchmark for satisfactory quality. A mirror’s surface waviness, attributed to manufacturing methods and tool dimensions, significantly impacts the overall image quality. Combining traditional manufacturing methods with computer-controlled techniques, which involve both large and small tools, emerges as an optimal approach to achieve the finest yet cost-effective figure (rms error) and waviness.

Surface Roughness and Slope RMS:

To ensure efficient energy transmission into imaging sensors or human eyes, the mirror’s surface roughness and slope root mean square (rms) play indispensable roles. These characteristics necessitate precise specification for mirrors with relatively smaller diameters. Employing a hybrid approach that integrates large and small tool polishing, mirrors acquire the capability to deliver peak performance while remaining economically viable.

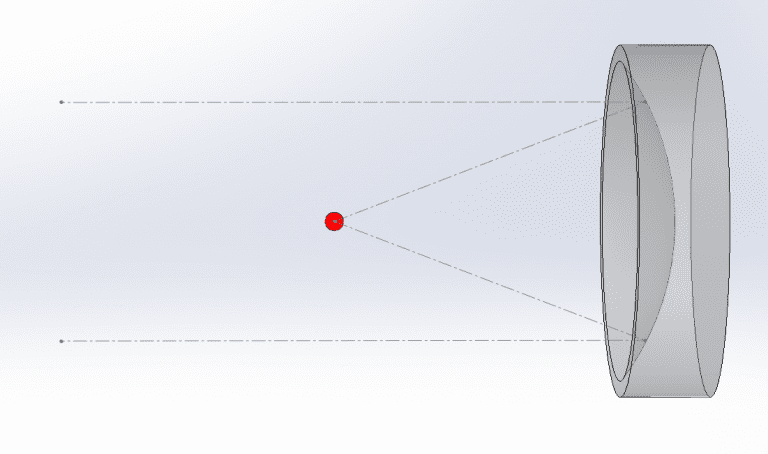

The Parabolic Mirror Advantage:

Parabolic mirrors, prominently utilized in astronomical telescopes, embody a distinctive advantage. With a characteristic f-number exceeding F4, these mirrors subtly deviate from spherical geometry. This minor aberration, while scarcely discernible, plays a pivotal role in governing image quality. Merging traditional manufacturing methods with computer-guided figure correction, these mirrors seamlessly reconcile the small divergence from spherical, culminating in superlative outcomes.

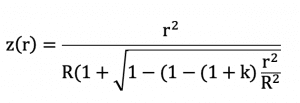

Technical Specifications and Parameters:

Parabolic mirrors conform to stringent tolerances, reflecting their meticulous construction. A typical tolerance is measured at 1/16 wave rms or an astonishing 40nm rms, serving as a testament to precision engineering. Coatings, an integral aspect, predominantly entail protected aluminum, with customization options available upon request. The choice of materials primarily revolves around quartz and Zerodur, underscoring the meticulous selection process underpinning mirror fabrication. The parabolic configuration is characterized by the parameter ‘k’, with its value set at -1, encapsulating the mirror’s inherent curvature.

Conclusion:

In the intricate realm of astronomical observation, the optimization of parabolic mirrors emerges as an avenue for elevating image quality. The amalgamation of precision engineering, meticulous manufacturing methodologies, and harmonious tool orchestration bequeaths telescopes with the ability to unravel the mysteries of the cosmos with unprecedented clarity and detail. The parabolic mirror stands as a beacon, embodying the equilibrium between scientific rigor and optical finesse, while bearing witness to the awe-inspiring vistas of the universe.

GREAT ARTICLE!

Share this article to gain insights from your connections!