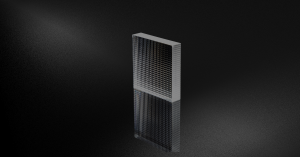

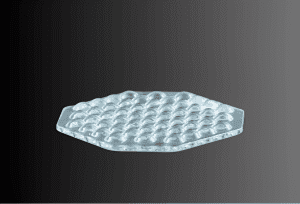

Microlens Arrays

High-Performance Beam Homogenizers for LiDAR, Imaging, and Sensing Systems

At Avantier, we design and manufacture precision microlens arrays for cutting-edge optical systems. Available in both off-the-shelf and fully custom configurations, our microlens arrays deliver uniform beam shaping, enhanced light collection, and superior optical performance across applications like autonomous driving, 3D imaging, biomedical optics, and AR/VR projection.

What Is a Microlens Array?

A microlens array (MLA) is a two-dimensional grid of tiny lenses (lenslets) designed to manipulate and homogenize light. MLAs are used to:

- Shape and redistribute non-Gaussian beams

- Increase efficiency in optical coupling

- Enable wide-angle and compact imaging systems

Avantier’s MLAs are available in UV, visible, and NIR-grade substrates, with customizable pitch, focal length, and layout.

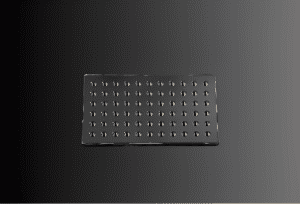

Types of Microlens Arrays

We offer two primary configurations optimized for different optical tasks:Fly’s Eye Condenser Arrays

- Dual-surface cylindrical lenslets

- Close-packed for uniform line or spot illumination

- Ideal for short working distances and large illuminated fields Applications: Laser projectors, industrial illumination, lithography

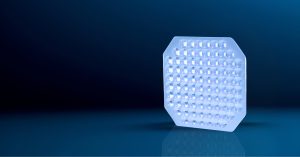

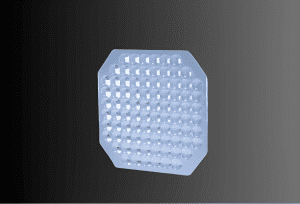

Square Grid Microlens Arrays

- High fill factor (up to 98%) elimiating zero-order hot spots

- Excellent for beam homogenization and shaping Applications: LiDAR emitters, laser beam shaping, endoscopic lighting

Microlens Arrays for Key Applications

Autonomous Vehicles & LiDAR

Microlens arrays are used in beam steering and depth-sensing modules to deliver precise, uniform illumination—critical for high-resolution mapping and object detection.Biomedical Imaging

MLAs allow compact camera modules and endoscopes to capture light more efficiently, enhancing contrast and brightness in low-light imaging.Wavefront Sensing & Adaptive Optics

Microlens arrays are key components in Shack-Hartmann sensors, enabling precise wavefront measurements in optical testing and astronomy.AR/VR and Projection Systems

Fly’s eye arrays are used to create uniform flat-top beams for displays, reducing glare and distortion in head-mounted displays and HUDs.Specifications

Diameter | +0, -0.1mm |

Surface accuracy | λ/2 @633nm or better |

Thickness | ±0.2mm |

Centration | ±0.04mm |

Surface quality | 20-10 |

Bevel | 0.2mm typical |

Material | SK2, BK7, UV-grade fused silica and more |

Lens Pitch & Focal Length | Customizable |

Custom Microlens Arrays

Off-the-shelf solutions often come with compromises. At Avantier, we offer custom microlens arrays manufactured using advanced techniques like:

- Semiconductor processing

- Laser micromachining

- Precision glass molding

Need a specific wavelength, pitch, or layout? We’ll design a microlens solution that matches your exact performance requirements.

🔧 Contact Our Optical Engineers

Why Avantier?

✔ ISO-Certified Precision Optics Manufacturer

✔ In-House Engineering & Design Support

✔ Rapid Prototyping & Global Delivery

✔ Proven in UV, VIS, and NIR Applications

FAQ

Q: Can I customize the shape or curvature of each microlens?

A: Yes. We support spherical, aspherical, and cylindrical microlens shapes.

Q: Do you provide MLAs for specific laser wavelengths?

A: Absolutely. We tailor designs to your source wavelength and application.

Q: What is the typical lead time for custom orders?

A: Standard prototypes ship in 4–6 weeks. Expedited options are available.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.