Avantier is a leading manufacturer of high-precision custom and stock aspheric lenses, engineered to deliver diffraction-limited performance for the world’s most demanding optical systems. From rapid prototyping to high-volume production, we provide the expertise needed to reduce spherical aberration and minimize system weight.

Strategic Applications

Our aspheric optics are integrated into advanced systems across critical industries:

- Medical & Life Sciences: Endoscopes, high-resolution DNA sequencing, and laser surgery tools.

- Aerospace & Defense: SWIR/LWIR thermal imaging and satellite reconnaissance.

- Automotive & LiDAR: Autonomous vehicle sensors and heads-up displays (HUD).

Industrial Metrology: 3D scanning and semiconductor inspection.

Why Choose Aspheric Lenses?

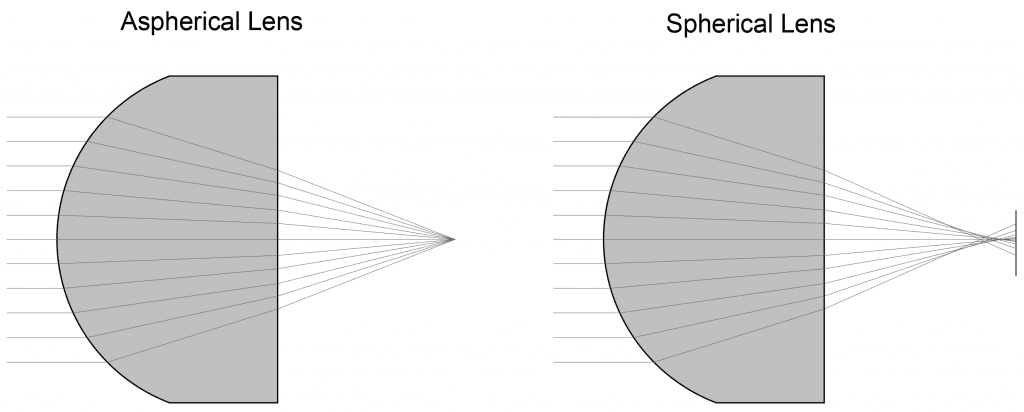

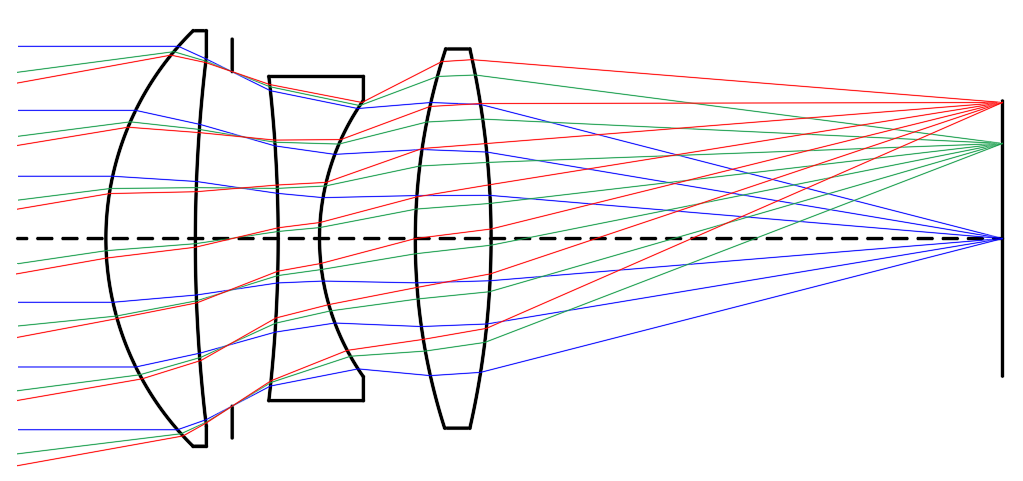

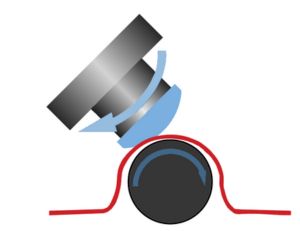

Traditional spherical lenses often suffer from marginal ray deviation, leading to blurred images. Aspheric lenses feature a complex, non-spherical surface profile that:

- Eliminates Spherical Aberration: Directs all incoming light to a single, precise focal point.

- Reduces Part Count: A single asphere can often replace multiple spherical elements, resulting in lighter, more compact assemblies.

Enhances Edge Clarity: Provides superior image quality across the entire field of view, even at high numerical apertures (NA).

Our Manufacturing Capabilities (5mm – 200mm)

Avantier utilizes state-of-the-art optical fabrication technology to meet sub-micron tolerances. Our in-house production ensures every lens meets your exact prescription.

| Diameter | 5 – 200mm |

| Diameter Tolerance | +0/-0.100mm – +0/-0.010mm |

| Asphere Figure Error (P – V) | 3μm – smaller than 0.06μm |

| Vertex Radius (Asphere) | ±0.5% – ±0.05% |

| Sag | 25mm max |

| Typical Slope Error | 1μm – 0.15μm per 1mm window |

| Centering (Beam Deviation) | 3 arcmin – 0.5 arcmin |

| Center Thickness Tolerance | ±0.100mm – ±0.010mm |

| Surface Quality (Scratch Dig) | 80-50, 40-20,10-5 |

| Aspheric Surface Metrology | Profilometry (2D & 3D) & Zygo Interferometry |

Custom Engineering & Prototyping

We don’t just manufacture; we partner with your engineering team. Avantier provides comprehensive support from Zemax design optimization to final assembly.Material Selection & Processes

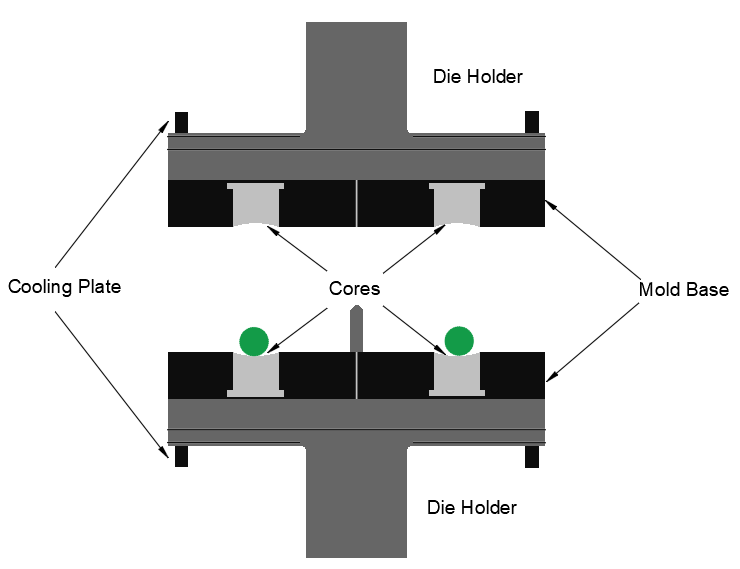

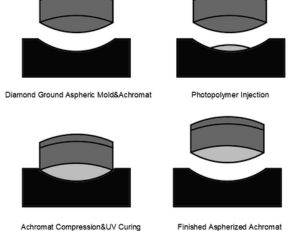

We work with a vast catalog of substrates to suit your specific wavelength requirements:- Precision Glass Molding: Ideal for high-volume, cost-effective production of low-temperature glass.

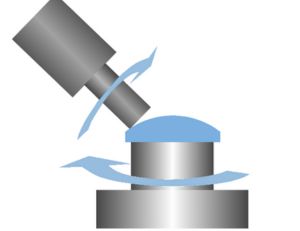

- CNC Grinding & Polishing: Best for medium volume and large diameter (up to 200mm) glass aspheres.

- Diamond Turning (SPDT): Specialized for Infrared materials (Ge, Si, ZnSe) and plastics.

- Magneto-Rheological Finishing (MRF): Used for achieving extreme surface accuracy and figure correction.

Stock Aspheric Lenses: Ready for Immediate Integration

For rapid prototyping and R&D, Avantier maintains a deep inventory of stock aspheres.- Laser-Grade Aspheres: Optimized for high-power beam shaping and focusing.

- Infrared (IR) Aspheres: Germanium and Silicon substrates for thermal sensing.

Stock Aspheric Lenses

Avantier maintains a comprehensive inventory of stock aspheric lenses for rapid delivery. These lenses cover a broad range of focal lengths, diameters, and materials, including laser-grade and uncoated optics.

Stock – Aspheric Lenses

| Part Number | Focal length (mm) | Back Focal length (mm) | Diameter (mm) | Thickness (mm) | Material | Price (USD) |

|---|---|---|---|---|---|---|

| AVTJF-0001 | 3.1 | 1.9 | 5.0 | 2.0 | H-F4 | Contact us |

| AVTJF-0002 | 3.7 | 2.4 | 5.0 | 2.0 | H-K51 | Contact us |

| AVTJF-0003 | 4.0 | 1.4 | 5.0 | 3.9 | H-K51 | Contact us |

| AVTJF-0004 | 5.6 | 3.3 | 8.0 | 4.0 | H-ZK2 | Contact us |

| AVTJF-0005 | 6.0 | 4.2 | 6.7 | 2.8 | H-K51 | Contact us |

| AVTJF-0006 | 6.5 | 3.2 | 10.0 | 5.0 | H-K51 | Contact us |

| AVTJF-0007 | 6.6 | 4.3 | 7.5 | 3.5 | H-K51 | Contact us |

| AVTJF-0008 | 7.4 | 4.8 | 8.5 | 4.0 | H-K51 | Contact us |

| AVTJF-0009 | 7.5 | 4.6 | 12.0 | 5.5 | H-K51 | Contact us |

| AVTJF-0010 | 7.6 | 4.0 | 13.0 | 6.3 | H-K51 | Contact us |

| AVTJF-0011 | 8.0 | 3.5 | 10.0 | 6.8 | H-K51 | Contact us |

| AVTJF-0012 | 8.0 | 3.7 | 12.7 | 7.5 | H-K51 | Contact us |

| AVTJF-0013 | 8.1 | 2.9 | 15.0 | 8.5 | H-K51 | Contact us |

| AVTJF-0014 | 8.3 | 5.6 | 16.0 | 7.0 | H-K9L | Contact us |

| AVTJF-0015 | 8.5 | 8.0 | 12.0 | 5.6 | H-K51 | Contact us |

| AVTJF-0016 | 9.0 | 8.0 | 6.3 | 1.7 | H-K51 | Contact us |

| AVTJF-0017 | 10.0 | 4.9 | 12.5 | 7.7 | H-K51 | Contact us |

| AVTJF-0018 | 10.4 | 7.4 | 12.0 | 5.6 | H-K51 | Contact us |

| AVTJF-0019 | 10.5 | 7.2 | 12.0 | 6.0 | H-K51 | Contact us |

| AVTJF-0020 | 11.0 | 6.0 | 16.0 | 8.0 | H-F4 | Contact us |

| AVTJF-0021 | 11.1 | 5.0 | 19.9 | 10.9 | H-K51 | Contact us |

| AVTJF-0022 | 12.0 | 6.3 | 15.0 | 8.6 | H-K51 | Contact us |

| AVTJF-0023 | 12.4 | 9.5 | 12.0 | 4.5 | H-K51 | Contact us |

| AVTJF-0024 | 12.5 | 7.1 | 20.0 | 9.0 | H-ZF2 | Contact us |

| AVTJF-0025 | 13.5 | 8.6 | 18.0 | 7.4 | H-K51 | Contact us |

| AVTJF-0026 | 14.0 | 10.2 | 12.9 | 5.7 | H-K9L | Contact us |

| AVTJF-0027 | 15.0 | 10.0 | 20.0 | 9.0 | H-K51 | Contact us |

| AVTJF-0028 | 15.3 | 14.6 | 24.0 | 9.0 | H-F3 | Contact us |

| AVTJF-0029 | 15.3 | 10.7 | 18.0 | 7.0 | H-K9L | Contact us |

| AVTJF-0030 | 16.0 | 9.1 | 20.0 | 10.5 | H-K51 | Contact us |

| AVTJF-0031 | 16.0 | 7.3 | 25.4 | 14.0 | H-K51 | Contact us |

| AVTJF-0032 | 16.3 | 10.4 | 20.0 | 9.0 | H-K9L | Contact us |

| AVTJF-0033 | 16.4 | 12.8 | 20.0 | 6.4 | H-K51 | Contact us |

| AVTJF-0034 | 16.7 | 9.5 | 24.9 | 11.0 | H-K51 | Contact us |

| AVTJF-0035 | 17.4 | 12.2 | 20.0 | 8.3 | H-K51 | Contact us |

| AVTJF-0036 | 18.0 | 11.2 | 24.0 | 10.4 | H-K51 | Contact us |

| AVTJF-0037 | 18.3 | 11.4 | 30.0 | 14.0 | H-K51 | Contact us |

| AVTJF-0038 | 19.0 | 15.7 | 12.0 | 5.0 | H-K51 | Contact us |

| AVTJF-0039 | 19.4 | 14.5 | 26.0 | 9.1 | H-K51 | Contact us |

| AVTJF-0040 | 19.7 | 12.9 | 24.0 | 10.4 | H-K51 | Contact us |

| AVTJF-0041 | 19.9 | 11.8 | 25.0 | 12.3 | H-K51 | Contact us |

| AVTJF-0042 | 21.6 | 11.0 | 34.9 | 19.0 | H-K51 | Contact us |

| AVTJF-0043 | 23.5 | 15.0 | 32.5 | 13.5 | H-K51 | Contact us |

| AVTJF-0044 | 24.0 | 14.7 | 30.0 | 14.1 | H-K51 | Contact us |

| AVTJF-0045 | 25.0 | 19.4 | 25.0 | 8.5 | H-K51 | Contact us |

| AVTJF-0046 | 25.6 | 16.7 | 30.0 | 13.5 | H-K51 | Contact us |

| AVTJF-0047 | 26.8 | 20.2 | 30.0 | 10.0 | H-K51 | Contact us |

| AVTJF-0048 | 28.5 | 18.6 | 40.0 | 15.0 | H-K9L | Contact us |

| AVTJF-0049 | 29.4 | 20.3 | 35.0 | 13.9 | H-K51 | Contact us |

| AVTJF-0050 | 29.5 | 20.9 | 40.0 | 15.5 | H-K9L | Contact us |

| AVTJF-0051 | 30.0 | 19.0 | 38.4 | 19.0 | H-K51 | Contact us |

| AVTJF-0052 | 32.0 | 17.0 | 50.8 | 25.0 | H-K51 | Contact us |

| AVTJF-0053 | 32.0 | 20.9 | 45.0 | 18.5 | H-K51 | Contact us |

| AVTJF-0054 | 32.0 | 20.3 | 40.0 | 11.8 | H-K51 | Contact us |

| AVTJF-0055 | 35.8 | 24.8 | 50.0 | 16.7 | H-K51 | Contact us |

| AVTJF-0056 | 39.8 | 25.6 | 60.0 | 26.0 | H-K51 | Contact us |

| AVTJF-0057 | 40.0 | 26.0 | 50.0 | 21.4 | H-K51 | Contact us |

| AVTJF-0058 | 49.2 | 29.5 | 75.0 | 30.0 | H-K51 | Contact us |

Stock - Uncoated Aspheric Lenses

| Part Number | Description | Dia. (mm) | EFL (mm) | NA | BFL (mm) | Substrate | Centering (arcmin) | CA (mm) | ET (mm) | CT (mm) | F/# | Shape of Back Surface | Wavelength Range (nm) | Price (USD) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AVTMF-0001 | 10mm Dia, 0.50 Numerical Aperture Uncoated | 10.00 +0.0/-0.1 | 10.00 @ 587.6nm | 0.50 | 7.48 | L-BAL35 | ≤5 | 9.00 | 1.69 | 4.00 ±0.1 | 1.00 | Plano | 330 – 2400 | $170.00 |

| AVTMF-0002 | 10mm Dia, 0.67 Numerical Aperture Uncoated | 10.00 +0.0/-0.1 | 7.50 @ 587.6nm | 0.67 | 4.51 | N-SF5 | ≤5 | 9.00 | 2.21 | 5.00 ±0.1 | 0.75 | Plano | 380 – 2500 | $170.00 |

| AVTMF-0003 | 12.5mm Dia, 0.50 Numerical Aperture Uncoated | 12.50 +0.0/-0.1 | 12.50 @ 587.6nm | 0.50 | 9.35 | L-BAL35 | ≤5 | 11.25 | 2.11 | 5.00 ±0.1 | 1.00 | Plano | 330 – 2400 | $190.00 |

| AVTMF-0004 | 12.5mm Dia, 0.66 Numerical Aperture Uncoated | 12.50 +0.0/-0.1 | 9.50 @ 587.6nm | 0.66 | 6.51 | N-SF5 | ≤5 | 11.25 | 1.60 | 5.00 ±0.1 | 0.76 | Plano | 380 – 2500 | $190.00 |

| AVTMF-0005 | 15mm Dia., 0.33 Numerical Aperture Uncoated | 15.00 +0.0/-0.1 | 22.50 @ 587.6nm | 0.33 | 19.98 | L-BAL35 | ≤5 | 13.50 | 1.80 | 4.00 ±0.1 | 1.50 | Plano | 330 – 2400 | $210.00 |

| AVTMF-0006 | 15mm Dia., 0.40 Numerical Aperture Uncoated | 15.00 +0.0/-0.1 | 18.75 @ 587.6nm | 0.40 | 15.92 | L-BAL35 | ≤5 | 13.50 | 1.82 | 4.50 ±0.1 | 1.25 | Plano | 330 – 2400 | $210.00 |

| AVTMF-0007 | 15mm Dia., 0.50 Numerical Aperture Uncoated | 15.00 +0.0/-0.1 | 15.00 @ 587.6nm | 0.50 | 11.54 | L-BAL35 | ≤5 | 13.50 | 2.04 | 5.50 ±0.1 | 1.00 | Plano | 330 – 2400 | $210.00 |

| AVTMF-0008 | 15mm Dia., 0.66 Numerical Aperture Uncoated | 15.00 +0.0/-0.1 | 11.25 @ 587.6nm | 0.66 | 6.85 | L-BAL35 | ≤5 | 13.50 | 1.94 | 7.00 ±0.1 | 0.75 | Plano | 330 – 2400 | $210.00 |

| AVTMF-0009 | 15mm Dia., 0.83 Numerical Aperture Uncoated | 15.00 +0.0/-0.1 | 9.00 @ 587.6nm | 0.83 | 4.81 | N-SF5 | ≤5 | 13.50 | 1.35 | 7.00 ±0.1 | 0.60 | Plano | 380 – 2500 | $320.00 |

| AVTMF-0010 | 20mm Dia., 0.50 Numerical Aperture Uncoated | 20.00 +0.0/-0.1 | 20.00 @ 587.6nm | 0.50 | 15.19 | L-BAL35 | ≤5 | 18.00 | 3.44 | 8.00 ±0.1 | 1.00 | Convex, R2=200mm | 330 – 2400 | $230.00 |

| AVTMF-0011 | 20mm Dia., 0.66 Numerical Aperture Uncoated | 20.00 +0.0/-0.1 | 15.00 @ 587.6nm | 0.66 | 9.16 | L-BAL35 | ≤5 | 18.00 | 3.05 | 9.60 ±0.1 | 0.75 | Convex, R2=200mm | 330 – 2400 | $230.00 |

| AVTMF-0012 | 20mm Dia., 0.8 Numerical Aperture Uncoated | 20.00 +0.0/-0.1 | 12.50 @ 587.6nm | 0.80 | 7.12 | N-SF5 | ≤5 | 18.00 | 1.91 | 9.00 ±0.1 | 0.63 | Plano | 380 – 2500 | $340.00 |

| AVTMF-0013 | 25mm Dia, 0.25 Numerical Aperture, Uncoated | 25.00 +0.0/-0.1 | 50.00 @ 587.6nm | 0.25 | 46.54 | L-BAL35 | ≤5 | 22.50 | 2.80 | 5.50 ±0.1 | 2.00 | Plano | 330 – 2400 | $250.00 |

| AVTMF-0014 | 25mm Dia., 0.33 Numerical Aperture Uncoated | 25.00 +0.0/-0.1 | 37.50 @ 587.6nm | 0.33 | 33.72 | L-BAL35 | ≤5 | 22.50 | 2.30 | 6.00 ±0.1 | 1.50 | Plano | 330 – 2400 | $250.00 |

| AVTMF-0015 | 25mm Dia., 0.40 Numerical Aperture Uncoated | 25.00 +0.0/-0.1 | 31.25 @ 587.6nm | 0.40 | 27.16 | L-BAL35 | ≤5 | 22.50 | 2.04 | 6.50 ±0.1 | 1.25 | Plano | 330 – 2400 | $250.00 |

| AVTMF-0016 | 25mm Dia., 0.50 Numerical Aperture Uncoated | 25.00 +0.0/-0.1 | 25.00 @ 587.6nm | 0.50 | 20.28 | L-BAL35 | ≤5 | 22.50 | 1.74 | 7.50 ±0.1 | 1.00 | Plano | 330 – 2400 | $250.00 |

| AVTMF-0017 | 25mm Dia., 0.66 Numerical Aperture Uncoated | 25.00 +0.0/-0.1 | 18.75 @ 587.6nm | 0.66 | 12.46 | L-BAL35 | ≤5 | 22.50 | 1.63 | 10.00 ±0.1 | 0.75 | Plano | 330 – 2400 | $250.00 |

| AVTMF-0018 | 25mm Dia., 0.83 Numerical Aperture Uncoated | 25.00 +0.0/-0.1 | 15.00 @ 587.6nm | 0.83 | 8.42 | N-SF5 | ≤5 | 22.50 | 1.64 | 11.00 ±0.1 | 0.60 | Plano | 380 – 2500 | $375.00 |

| AVTMF-0019 | 30mm Dia., 0.50 Numerical Aperture Uncoated | 30.00 +0.0/-0.1 | 30.00 @ 587.6nm | 0.50 | 22.99 | L-BAL35 | ≤5 | 27.00 | 4.81 | 11.70 ±0.1 | 1.00 | Convex, R2=300mm | 330 – 2400 | $300.00 |

| AVTMF-0020 | 30mm Dia., 0.66 Numerical Aperture Uncoated | 30.00 +0.0/-0.1 | 22.50 @ 587.6nm | 0.66 | 13.73 | L-BAL35 | ≤5 | 27.00 | 4.57 | 14.40 ±0.1 | 0.75 | Convex, R2=300mm | 330 – 2400 | $300.00 |

| AVTMF-0021 | 30mm Dia., 0.86 Numerical Aperture Uncoated | 30.00 +0.0/-0.1 | 17.50 @ 587.6nm | 0.86 | 9.43 | N-SF5 | ≤5 | 27.00 | 1.78 | 13.50 ±0.1 | 0.58 | Plano | 380 – 2500 | $430.00 |

| AVTMF-0022 | 40mm Dia., 0.50 Numerical Aperture Uncoated | 40.00 +0.0/-0.1 | 40.00 @ 587.6nm | 0.50 | 30.68 | L-BAL35 | ≤5 | 36.00 | 6.39 | 15.50 ±0.1 | 1.00 | Convex R2=400mm | 330 – 2400 | $420.00 |

| AVTMF-0023 | 40mm Dia., 0.66 Numerical Aperture Uncoated | 40.00 +0.0/-0.1 | 30.00 @ 587.6nm | 0.66 | 20.60 | L-BAL35 | ≤5 | 36.00 | 2.56 | 15.50 ±0.1 | 0.75 | Convex R2=400mm | 330 – 2400 | $420.00 |

| AVTMF-0024 | 40mm Dia., 0.80 Numerical Aperture Uncoated | 40.00 +0.0/-0.1 | 25.00 @ 587.6nm | 0.80 | 15.73 | N-SF5 | ≤5 | 36.00 | 1.49 | 15.50 ±0.1 | 0.63 | Plano | 380 – 2500 | $540.00 |

| AVTMF-0025 | 50mm Dia., 0.50 Numerical Aperture Uncoated | 50.00 +0.0/-0.1 | 50.00 @ 587.6nm | 0.50 | 38.33 | L-BAL35 | ≤5 | 45.00 | 8.01 | 19.40 ±0.1 | 1.00 | Convex, R=500mm | 330 – 2400 | $500.00 |

| AVTMF-0026 | 50mm Dia., 0.66 Numerical Aperture Uncoated | 50.00 +0.0/-0.1 | 37.50 @ 587.6nm | 0.66 | 25.74 | L-BAL35 | ≤5 | 45.00 | 3.23 | 19.40 ±0.1 | 0.75 | Convex, R=500mm | 330 – 2400 | $500.00 |

| AVTMF-0027 | 50mm Dia., 0.83 Numerical Aperture Uncoated | 50.00 +0.0/-0.1 | 30.00 @ 587.6nm | 0.83 | 18.04 | N-SF5 | ≤5 | 45.00 | 1.44 | 20.00 ±0.1 | 0.60 | Plano | 380 – 2500 | $720.00 |

| AVTMF-0028 | 75mm Dia., 0.33 Numerical Aperture Uncoated | 75.00 +0.0/-0.1 | 112.50 @ 587.6nm | 0.33 | 101.42 | N-BK7 | ≤5 | 67.50 | 4.13 | 16.80 ±0.1 | 1.50 | Plano | 350 – 2200 | $690.00 |

| AVTMF-0029 | 75mm Dia., 0.50 Numerical Aperture Uncoated | 75.00 +0.0/-0.1 | 75.00 @ 587.6nm | 0.50 | 58.25 | N-BK7 | ≤5 | 67.50 | 4.99 | 25.40 ±0.1 | 1.00 | Plano | 350 – 2200 | $690.00 |

| AVTMF-0030 | 75mm Dia., 0.63 Numerical Aperture Uncoated | 75.00 +0.0/-0.1 | 60.00 @ 587.6nm | 0.63 | 45.77 | N-SF5 | ≤5 | 67.50 | 4.73 | 23.80 ±0.1 | 0.80 | Plano | 380 – 2500 | $690.00 |

| AVTMF-0031 | 100mm Dia., 0.33 Numerical Aperture Uncoated | 100.00 +0.0/-0.1 | 150.00 @ 587.6nm | 0.33 | 135.50 | N-BK7 | ≤5 | 90.00 | 5.11 | 22.00 ±0.1 | 1.50 | Plano | 350 – 2200 | $880.00 |

| AVTMF-0032 | 100mm Dia., 0.50 Numerical Aperture Uncoated | 100.00 +0.0/-0.1 | 100.00 @ 587.6nm | 0.50 | 78.18 | N-BK7 | ≤5 | 90.00 | 5.90 | 33.10 ±0.1 | 1.00 | Plano | 350 – 2200 | $880.00 |

| AVTMF-0033 | 100mm Dia., 0.63 Numerical Aperture Uncoated | 100.00 +0.0/-0.1 | 80.00 @ 587.6nm | 0.63 | 61.35 | N-SF5 | ≤5 | 90.00 | 5.78 | 31.20 ±0.1 | 0.80 | Plano | 380 – 2500 | $880.00 |

| AVTMF-0034 | 150mm Dia., 0.33 Numerical Aperture Uncoated | 150.00 +0.0/-0.1 | 225.00 @ 587.6nm | 0.33 | 204.04 | N-BK7 | ≤5 | 128.00 | 6.46 | 31.80 ±0.1 | 1.50 | Plano | 350 – 2200 | $1,950.00 |

| AVTMF-0035 | 150mm Dia., 0.50 Numerical Aperture Uncoated | 150.00 +0.0/-0.1 | 150.00 @ 587.6nm | 0.50 | 118.16 | N-BK7 | ≤5 | 128.00 | 7.51 | 48.30 ±0.1 | 1.00 | Plano | 350 – 2200 | $1,950.00 |

| AVTMF-0036 | 150mm Dia., 0.63 Numerical Aperture Uncoated | 150.00 +0.0/-0.1 | 120.00 @ 587.6nm | 0.63 | 92.86 | N-SF5 | ≤5 | 128.00 | 7.30 | 45.40 ±0.1 | 0.80 | Plano | 380 – 2500 | $1,950.00 |

| AVTMF-0037 | 200mm Dia., 0.33 Numerical Aperture Uncoated | 200.00 +0/-0.1 | 300.00 @ 587.6nm | 0.33 | 272.57 | N-BK7 | ≤5 | 170.00 | 7.82 | 41.60 ±0.1 | 1.50 | Plano | 350 – 2200 | $3,700.00 |

Stock - High Precision Laser Grade Aspheric Lenses

| Part Number | Description | Compatible Brands | Dia. (mm) | EFL (mm) | NA | BFL (mm) | Substrate | Centering (arcmin) | CA (mm) | ET (mm) | CT (mm) | F/# | Shape of Back Surface | Unit Price (USD) | Price (USD) *5-9 pcs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AVTGF-0001 | 25.4mm Dia x 50.8mm FL, 355nm V-Coat | Edmund Optics (39-556) | 25.40 +0.00/-0.05 | 50.80 @ 355nm | 0.25 | 45.39 | Fused Silica (Corning 7980) | <1 | 21.40 | 4.54 | 7.98 | 2 | Plano | $730.00 | $720.00 |

| AVTGF-0002 | 25.4mm Dia x 50.8mm FL, 532nm V-Coat | Edmund Optics (39-558) | 25.40 +0.00/-0.05 | 50.80 @ 532nm | 0.25 | 45.36 | Fused Silica (Corning 7980) | <1 | 21.40 | 4.40 | 7.90 | 2 | Plano | $825.00 | $800.00 |

| AVTGF-0003 | 25.4mm Dia x 50.8mm FL, 1064nm V-Coat | Edmund Optics (39-560) | 25.40 +0.00/-0.05 | 50.80 @ 1064nm | 0.25 | 45.03 | Fused Silica (Corning 7980) | <1 | 21.40 | 4.70 | 8.40 | 2 | Plano | $825.00 | $800.00 |

| AVTGF-0004 | 50.8mm Dia x 101.6mm FL, 355nm V-Coat | Edmund Optics (39-563) | 50.80 +0.00/-0.05 | 101.60 @ 355nm | 0.25 | 97.96 | Fused Silica (Corning 7980) | <1 | 46.80 | 4.11 | 10.98 | 2 | Plano | $950.00 | $925.00 |

| AVTGF-0005 | 50.8mm Dia x 101.6mm FL, 532nm V-Coat | Edmund Optics (39-565) | 50.80 +0.00/-0.05 | 101.60 @ 532nm | 0.25 | 93.95 | Fused Silica (Corning 7980) | <1 | 46.80 | 4.10 | 11.20 | 2 | Plano | $1,125.00 | $1,100.00 |

| AVTGF-0006 | 50.8mm Dia x 101.6mm FL, 1064nm V-Coat | Edmund Optics (39-567) | 50.80 +0.00/-0.05 | 101.60 @ 1064nm | 0.25 | 94.70 | Fused Silica (Corning 7980) | <1 | 46.80 | 2.69 | 10.00 | 2 | Plano | $1,125.00 | $1,100.00 |

Stock – Germanium Aspheric Lenses

| Part Number | Description | Dia. (mm) | EFL (mm) | NA | BFL (mm) | Asphere Figure Error(RMS) | Centering (arcmin) | CA (mm) | ET (mm) | CT (mm) | F/# | Radius R2 (mm) | Shape of Back Surface | Price (USD) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AVTZF-0001 | 12.5mm Dia x 9.5mm FL Uncoated, Ge Aspheric Lens | 12.50 +0.00/-0.10 | 9.50 @ 8000nm | 0.65 | 8.25 | λ/6 | ≤5 | 11.25 | 4.36 | 5.00 ±0.10 | 0.76 | Infinite | Plano | $550.00 |

| AVTZF-0002 | 12.5mm Dia x 12.5mm FL Uncoated, Ge Aspheric Lens | 12.50 +0.00/-0.10 | 12.50 @ 8000nm | 0.50 | 11.75 | λ/6 | ≤5 | 11.25 | 2.50 | 3.00 ±0.10 | 1.00 | Infinite | Plano | $490.00 |

| AVTZF-0003 | 12.5mm Dia x 25mm FL Uncoated, Ge Aspheric Lens | 12.50 +0.00/-0.10 | 25.00 @ 8000nm | 0.25 | 24.25 | λ/6 | ≤5 | 11.25 | 2.74 | 3.00 ±0.10 | 2.00 | Infinite | Plano | $490.00 |

| AVTZF-0004 | 12.5mm Dia x 37.5mm FL Uncoated, Ge Aspheric Lens | 12.50 +0.00/-0.10 | 37.50 @ 8000nm | 0.16 | 36.75 | λ/6 | ≤5 | 11.25 | 2.83 | 3.00 ±0.10 | 3.00 | Infinite | Plano | $590.00 |

| AVTZF-0005 | 25mm Dia x 12.5mm FL Uncoated, Ge Aspheric Lens | 25.00 +0.0/-0.1 | 12.50 @ 4000nm | 1.00 | 11.61 | λ/6 | ≤5 | 22.50 | 2.50 | 4.24 ±0.10 | 0.50 | 435.187 | Convex | $970.00 |

| AVTZF-0006 | 25mm Dia x 15mm FL Uncoated, Ge Aspheric Lens | 25.00 +0.0/-0.1 | 15.00 @ 4000nm | 0.83 | 14.00 | λ/6 | ≤5 | 22.50 | 2.47 | 4.00 ±0.10 | 0.60 | Infinite | Plano | $900.00 |

| AVTZF-0007 | 25mm Dia x 20mm FL Uncoated, Ge Aspheric Lens | 25.00 +0.0/-0.1 | 20.00 @ 4000nm | 0.63 | 19.08 | λ/6 | ≤5 | 22.50 | 2.50 | 3.70 ±0.10 | 0.79 | Infinite | Plano | $820.00 |

| AVTZF-0008 | 25mm Dia x 25mm FL Uncoated, Ge Aspheric Lens | 25.00 +0.0/-0.1 | 25.00 @ 4000nm | 0.50 | 22.51 | λ/6 | ≤5 | 22.50 | 2.32 | 3.45 ±0.10 | 1.00 | 37.8 | Concave | $775.00 |

| AVTZF-0009 | 25mm Dia x 30mm FL Uncoated, Ge Aspheric Lens | 25.00 +0.0/-0.1 | 30.00 @ 4000nm | 0.42 | 27.52 | λ/6 | ≤5 | 22.50 | 2.29 | 3.25 ±0.10 | 1.19 | 40 | Concave | $775.00 |

| AVTZF-0010 | 25mm Dia x 40mm FL Uncoated, Ge Aspheric Lens | 25.00 +0.0/-0.1 | 40.00 @ 4000nm | 0.31 | 37.89 | λ/6 | ≤5 | 22.50 | 2.38 | 3.10 ±0.10 | 1.61 | 65.6 | Concave | $775.00 |

| AVTZF-0011 | 25mm Dia x 50mm FL Uncoated, Ge Aspheric Lens | 25.00 +0.0/-0.1 | 50.00 @ 4000nm | 0.25 | 48.44 | λ/6 | ≤5 | 22.50 | 2.45 | 3.00 ±0.10 | 2.00 | 142.9 | Concave | $775.00 |

| AVTZF-0012 | 25mm Dia x 75mm FL Uncoated, Ge Aspheric Lens | 25.00 +0.0/-0.1 | 75.00 @ 4000nm | 0.17 | 72.30 | λ/6 | ≤5 | 22.50 | 2.39 | 2.80 ±0.10 | 2.94 | 78 | Concave | $775.00 |

| AVTZF-0013 | 50mm Dia x 25mm FL Uncoated, Ge Aspheric Lens | 50.00 +0.0/-0.1 | 25.00 @ 4000nm | 1.00 | 20.64 | λ/6 | ≤5 | 45.00 | 2.50 | 7.75 ±0.10 | 0.50 | 49.34 | Concave | $1,550.00 |

| AVTZF-0014 | 50mm Dia x 50mm FL Uncoated, Ge Aspheric Lens | 50.00 +0.0/-0.1 | 50.00 @ 4000nm | 0.50 | 45.92 | λ/6 | ≤5 | 45.00 | 2.52 | 5.10 ±0.10 | 1.00 | 62.38 | Concave | $1,550.00 |

Real-World Applications & Case Studies

Our engineering team doesn’t just manufacture lenses; we solve complex optical challenges. Explore our recent work in high-precision aspheric integration:

- Infrared Lens Design for Scientific Research: Optimized for Design for Manufacturing (DFM), we developed high-performance IR aspheres that maintain thermal stability and precision in sensitive laboratory environments.

- Cold Atom Trapping & Imaging: We designed a custom objective lens system capable of trapping and imaging single atoms, requiring extreme numerical aperture (NA) and diffraction-limited performance.

- Reverse Engineering of Complex Objectives: Leveraging our metrology suite, we successfully reverse-engineered and improved upon existing objective and projection lens designs to enhance throughput and reduce aberrations.

Technical Resource: Performance Comparison

When designing a system, choosing the right lens geometry is critical for MTF (Modulation Transfer Function) performance.

Spherical vs. Aspheric Spot Size (25mm f/1 Lens)

| Object Angle (°) | Spherical Spot Size (μm) | Aspheric Spot Size (μm) |

| 0.0 | 710.01 | 71.43 |

| 0.5 | 710.96 | 3.91 |

| 1.0 | 713.84 | 8.11 |

Optical Advantages of Aspheric Lenses

Spherical Aberration Correction – Aspheric lenses are expertly engineered to direct all incoming light rays to a single focal point, eliminating spherical aberration. This enhances image sharpness, minimizes blur, and ensures optimal focus across the field—making them ideal for high-precision imaging systems, laser collimation, and optical instrumentation.

Aspheric vs. High-Index and Pancake Lenses – While high-index lenses use material properties to improve light bending, aspheric lenses optimize surface geometry for superior aberration correction. Compared to compact pancake lenses, aspheric lenses deliver significantly better edge-to-edge image clarity and reduced distortion.

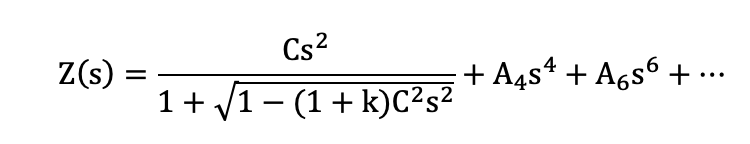

Advanced Surface Geometry & Freeform Capabilities – Avantier supports both rotationally symmetric and freeform aspheric designs. These profiles feature curvature that varies with radial distance from the optical axis, offering greater flexibility in correcting complex aberrations. Key surface profile metrics include:

- Qbfs – RMS slope departure from a best-fit sphere

- Qcon – Sag departure from a base conic

Structure of an Aspheric Lens

Aspheric lenses are optical elements with a radially varying curvature, allowing them to correct aberrations more effectively than spherical lenses. Unlike traditional lenses with uniform curvature, aspheric surfaces are designed to bring light to a sharper, more precise focus.

These lenses are widely used in:

- Automotive sensors

- LED optics

- Medical imaging

- High-resolution cameras

- Laser systems

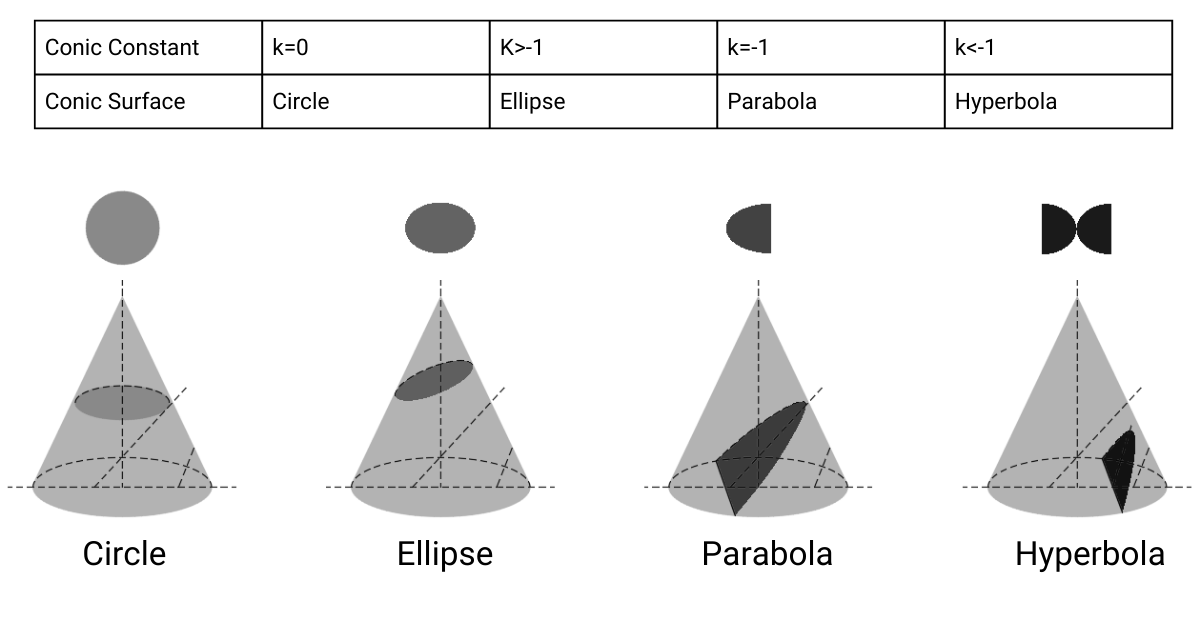

The surface of a rotationally symmetric asphere is mathematically defined using a sag equation:

Where:

- Z: sag of surface parallel to the optical axis

- s: radial distance from the optical axis

- C: curvature, inverse of radius

- k: conic constant

- A4, A6, …: 4th, 6th, … order aspheric coefficients

When all coefficients are zero, the surface is a standard conic shape—elliptical, parabolic, or hyperbolic, depending on the value of k.

Spherical vs. Aspheric Performance Comparison

As shown in the chart below, a 25 mm f/1 spherical lens produces significantly larger spot sizes compared to an equivalent aspheric lens:

| Object Angle (°) | Spherical Spot Size (μm) | Aspheric Spot Size (μm) |

| 0.0 | 710.01 | 71.43 |

| 0.5 | 710.96 | 3.91 |

| 1.0 | 713.84 | 8.11 |

MTF Comparison: All Spherical vs. Aspheric Triplet Design

This table compares the Modulation Transfer Function (MTF) performance of two triplet lenses—one with only spherical surfaces, and the other with a single aspheric surface:

| Object Angle (°) | All Spherical (Tangential/Sagittal) | With Aspheric (Tangential/Sagittal) |

| 0.0 | 13.3 / 13.3 | 61.9 / 61.9 |

| 7.0 | 14.9 / 14.9 | 31.1 / 40.9 |

| 10.0 | 17.3 / 14.8 | 36.3 / 41.5 |

Avantier measures and controls all critical aspects of surface accuracy:

- Form Error – Large-scale deviations, RMS or peak-to-valley

- Waviness – Mid-frequency undulations (slope error)

- Surface Roughness – High-frequency texture, relevant for scatter & laser performance

- Radius Error – Curvature deviation corrected by focus tuning

Manufacturing Methods at Avantier

| Method | Benefits |

| Precision Glass Molding | Cost-efficient for high-volume production |

| Precision Polishing & MRF | High-precision shaping for low-to-medium volume applications |

| SPDT Diamond Turning | Excellent for plastics, metals, mold creation & freeforms |

| Polymer Molding/Injection | Lightweight, low-cost optics for AR/VR, illumination, and consumer |

How to Select the Right Aspheric Lens for Your Application

Key Considerations

- UV, VIS, IR compatibility

- Coating options (AR, IR, broadband)

- Mechanical integration (CAD, full prescription)

- Budget and production scale

Application-Based Lens Guide

| Application | Recommended Lens Type | Key Features |

| High-NA Imaging | Precision Polished Aspheres | Diffraction-limited performance, glass/plastic options |

| Laser & Volume Systems | Precision Molded Aspheres | Ideal for laser collimation, barcode, data reading |

| Broadband Color Correction | Color-Corrected Aspheric Lenses | Chromatic + spherical correction, hybrid designs |

| Thermal / IR Imaging | Infrared Aspheric Lenses | Ge/ZnSe/ZnS optics for MWIR, LWIR, thermal sensing |

Frequently Asked Questions

How does Avantier verify the surface accuracy of custom aspheres?

Q: How does Avantier verify the surface accuracy of custom aspheres?

A: We use advanced metrology, including non-contact 3D profilometry and laser interferometry. This ensures that the sag profile matches your design coefficients (Qbfs, Qcon) with nanometer precision.

What is the typical lead time for custom aspheric prototypes?

Q: How have advances in manufacturing made aspheric lenses more versatile and cost-effective?

A: Depending on material availability and complexity, typical lead times for custom prototypes range from 3 to 6 weeks. We also offer expedited “Fast-Track” services for urgent projects.

Can you replace my existing multi-lens assembly with a single asphere?

Q: Can you replace my existing multi-lens assembly with a single asphere?

A: In many cases, yes. Our optical engineers can perform a “Lens Count Reduction” analysis to simplify your design, reduce weight, and lower assembly costs without sacrificing optical performance.

Related Content

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.