Reverse Optical Engineering

If you need to produce a lens or optical assembly but only have a finished product and no specifications, reverse optical engineering services may be the solution. Reverse optical engineering involves working backward from an existing sample or prototype to create a set of plans and specifications that enable you to recreate the needed optical component. Whether you require an exact replica or an improved version that outperforms the original, our team is ready to collaborate with you to produce the custom lens your application demands.

When to Consider for Your Optics Needs?

Reverse optical engineering may not always be as cost-effective as designing a new product from scratch, but there are numerous situations where it proves essential. Your critical application might rely on a unique optical system or lens that’s solely available from one supplier. Everything runs smoothly until the day that supplier discontinues the product. Suddenly, you’re at a standstill—unless you partner with a custom optics manufacturer like Avantier, who can reverse engineer the discontinued component and get your project back on track.

Reverse engineering can also be a valuable solution when you aim to enhance a specific off-the-shelf lens or optical component to align perfectly with your application. In this scenario, a comprehensive understanding of the original component can help you create a significantly improved version. For example, suppose the optic system you currently use functions well but has a low damage threshold. We can assist you in developing a more robust system with the same functionality.

Benefits include:

- Ownership: When we reverse engineer a component for you and design a new optical design based on that, the design belongs to you.

- Optimized performance: Reverse engineering empowers you to transition from a product that almost works to one that precisely matches your specifications.

- Lower costs: While reverse engineering involves a detailed process, it might enable you to produce your own lower-cost duplicate of an expensive lens.

How Reverse Optical Engineering Works?

Reverse engineering necessitates a deep knowledge and understanding of the optical device to be replicated, including every detail of its high-precision optical alignment and assembly. We begin by comprehensively testing the existing optical system, evaluating its basic functionality and conducting additional tests to analyze its performance under various conditions.

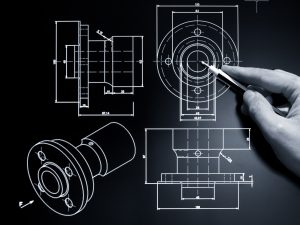

Next, we meticulously disassemble the system and map its construction. Optical and mechanical components are separated, and detailed technical drawings are created to document their arrangement and attributes.

The disassembled optical components are then analyzed using state-of-the-art metrology equipment. This enables us to determine crucial specifications for each lens, including dimensions, radius, surface accuracy, air space, centering, coating, and refractive index. The specific test equipment and design may vary depending on the type of component being analyzed. Armed with these diagrams and precise specifications, we embark on the final phase: redesign. This phase involves leveraging our newfound knowledge to design the custom lens or assembly that meets your exact requirements, whether that entails a close replication of the original design or modifications to specific aspects.

To summarize, reverse optical engineering is the process of analyzing and recreating existing optical components when original designs are unavailable. It involves reverse engineering processes where a sample lens or optical system is carefully inspected, disassembled, and tested using high quality computer aided design (CAD) models to ensure the accuracy of the recreated component. Validation procedures include studying the optical components using advanced test equipment to analyze lens radius, refractive index, and coating. The parts are fully examined before assembling the lens again, allowing for precise replication or improvement. Custom optic systems can be designed, and high-precision methods like diamond turning and injection molding may be used to manufacture components. This approach is essential when original optics are discontinued or need improvement for optimized performance.

Reverse Optical Engineering Services

At Avantier we pride ourselves on exceptional customer service and our ability to provide a tailored experience to anyone requiring unique optical parts. With over two decades of experience in North America in optical engineering, we possess the tools and expertise to reverse engineer a wide range of optical devices. We’re dedicated to helping you realize your vision. Contact us today to schedule a complimentary consultation or request a quote for your next project.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.