F-Theta Lenses

F-theta lenses are the optics of choice for laser scanning, engraving, and cutting systems. At Avantier, we produce high-performing custom F-theta lenses for a wide range of clients.

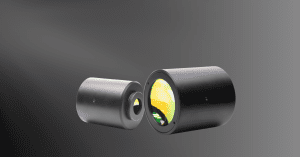

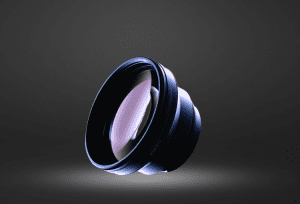

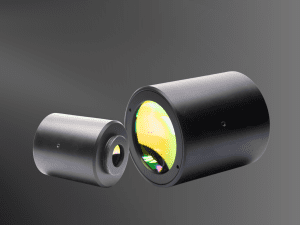

An f-theta lens (also known as a plane field objective or scan lens) is not just one optical piece; it is an assembly containing three or four lenses pre-aligned and mounted within sturdy housing for easy use. While an ordinary lens can be used to focus a laser beam on a spherical surface, using a F-theta lens allows you to work with a plane focusing surface. It also features a spot size that is almost constant over the scan field. Additionally, the laser spot position is proportional to the scan angle, making it incredibly useful for laser applications.

Applications of F-Theta Lenses

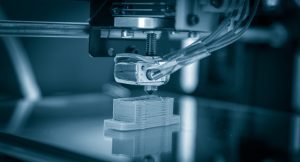

F-theta lenses are essential components in many laser scanner systems, particularly those requiring high resolution and a flat imaging field. In materials processing, laser drilling, welding, and cutting of synthetic materials with laser often rely on F-theta lenses, as do engraving and labeling systems and image transfer.

In biotechnics, these lenses play a crucial role in applications such as ophthalmology and confocal microscopy.

Why Choose F-Theta Lenses For Scanning Applications

Scan mirrors or a galvanometer are typically used to move a laser beam linearly in a scanning system. This enables the laser to be guided for drilling, cutting, or engraving. If an ordinary lens were used to focus the laser, the curved lens surface would lead to changes in the beam profile as the distance from the optical axis changes. These changes in the beam profile could lead to inconsistency in optical power and result in manufacturing defects.

A traditional flat-field scanning lens partially addresses this issue by focusing light on a flat image plane. However, they introduce other aberrations and errors due to the non-linear movement of the image as the angle changes.

F-theta lenses eliminate these manufacturing errors, such as pincushion or barrel distortion, enabling consistent and reliable laser-powered materials processing.

Key Parameters of a F-Theta Lens and Scanning System

When designing an F-theta lens for your application, key parameters to keep in mind are operating wavelength, spot size, and scan field diameter (SFD).

The operating wavelength is the wavelength of the laser that you’ll be working with. Spot size refers to the width of the laser beam. The scan field diameter SFD or scan length of an F-theta lens is defined as the diagonal length of the square in which the beam can be focused by the lens.

Another important feature of a scanning system is the output scan angle or OSA. This is the angle between the normal of the image plane and the output laser beam (the beam after it has passed through the scan lens). For a telecentric lens, the OSA will always be zero; otherwise, it will vary slightly across the image field.

Other essential parameters include working distance, which refers to the distance between the lens housing and the paraxial focus point, and field curvature, which is the deviation from a flat image plane. Even though F-theta lenses are designed to reduce field curvature, some distortion and curvature will still exist. For example, placing the zero-curvature point at the midrange of the scan can help minimize the impact. Additionally, diffraction limited performance may be a critical consideration, ensuring minimal loss of beam quality.

By focusing on these elements, you can optimize your F-theta lens for precision and accuracy in your system.

Factory Standard

Lens Design | Compact design with 3 to 4 elements |

Transmittance | >90% |

Distortion (Max.) | <0.25% |

Focal Length | Available from 63mm to 635mm |

Custom Optical Coating | Working wavelength range from UV to visible to infrared |

Lens Performance | Customized to fit specific application needs |

Custom F-Theta Lenses at Avantier

Avantier specializes in custom F-theta lenses built to order for clients in industry, research, and medicine. Our optical engineers and designers have years of experience crafting high-performance optical components, and every piece that leaves our factory is carefully tested to meet the highest standards. Please contact us today to place a custom order or set up an initial consultation.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.