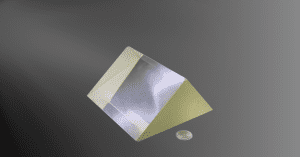

Precision Large-Sized Reflector Substrates

Precision large-sized reflector substrates refer to high-quality, accurately manufactured surfaces that are used as reflective elements in optical systems. These substrates are designed to efficiently reflect light or other electromagnetic radiation with minimal distortion or loss, and they are used in a variety of applications, including telescopes, satellite communication systems, laser systems, and more. Here are some key points:

- Size: These substrates are typically larger in size compared to standard optical components. The specific dimensions can vary widely depending on the application, but they are often quite substantial, with diameters or dimensions measured in meters or even tens of meters.

- Material: The choice of material for the substrate depends on the wavelength of the radiation being reflected. Common materials include aluminum, silver, or gold-coated surfaces for visible and infrared light, while materials like carbon composites or metals with specialized coatings may be used for radio waves or microwaves.

- Precision Manufacturing: Achieving high precision in the shape and surface quality of large reflector substrates is critical for their performance. Precision manufacturing techniques such as diamond turning, CNC machining, and advanced polishing processes are used to create the desired shape and smooth surface finish.

- Surface Accuracy: The surface of a precision reflector substrate must conform closely to a specific shape, such as a paraboloid or hyperboloid, depending on the optical system’s design. Even minor deviations from the desired shape can result in degraded performance.

- Applications: Precision large-sized reflector substrates are used in a wide range of applications. For example, in radio telescopes, large reflector substrates are used to capture and focus radio waves from distant celestial objects. In satellite communication systems, they are used to direct signals from ground stations to satellites in orbit. In optical telescopes, they help collect and focus light from distant stars and galaxies.

- Challenges: Manufacturing and maintaining can be challenging due to their size and the need for high precision. Temperature variations and environmental factors can affect the shape and performance of these substrates, so they often require careful monitoring and adjustments.

- Research and Development: Advances in materials science and manufacturing techniques continue to drive improvements in precision large-sized reflector substrates. Researchers are constantly working to develop new materials and coatings that enhance reflectivity and reduce losses.

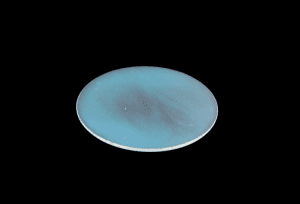

Factory Standards

Material | BK7/H‐K9L (or other suitable material) |

Dimensions | 70x400x20mm |

Front Surface Flatness | λ/10 and at 633 nm |

Surface Quality | 60‐40 Scratch & Dig |

Highly reflective coating | 400‐2500nm |

Custom Large Sized Reflector Substrates

Feel free to contact Avantier for inquiries about manufacturing limits or custom large sized reflector substrates. Our dedicated design team is eager to collaborate with you in identifying the optimal custom optical solution tailored to your specific application.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.