Enhancing Optical Performance for Laser Applications

Plano-concave lenses are optical lenses that feature a flat surface and one concave surface. With a negative focal length, these lenses find applications in light projection, beam expansion, and focal length extension for optical systems. Avantier specializes in manufacturing a diverse range of plano-concave lenses optimized for various spectra, including ultraviolet (UV), visible, and infrared (IR). Our facility offers lenses with diameters ranging from 2.33 mm to 1000 mm, and we provide both coated and uncoated options. Additionally, our design engineers are available to collaborate with you in creating custom lenses tailored to your specific requirements.

To ensure superior quality, our plano-concave lenses adhere to rigorous factory standards. The specifications encompass vital parameters such as shape, diameter tolerance, thickness tolerance, radius, focal length tolerance, surface quality, surface flatness, centration, and clear aperture. Notably, our lenses are available with high power AR coatings, ensuring maximum efficiency and durability in high-power laser applications.

Plano-Concave Lenses Capabilities

| Specifications | Factory Standards | Manufacturing Limit |

Dimension Tolerance</3> |

+/-0.05mm</3> |

+/-0.01mm</3> |

Center Thickness Tolerance</3> |

+/-0.05mm</3> |

+/-0.01mm</3> |

Radius Tolerance</3> |

+/-0.3%</3> |

+/-0.1%</3> |

Surface Quality(S/D)</3> |

40-20</3> |

10-5</3> |

Irregularity</3> |

1/4 Lambda</3> |

< 1/10 Lambda</3> |

Centration(arc min)</3> |

3′</3> |

1′</3> |

Plano-Concave Lens Specifications

Material selection is crucial for the performance of plano-concave lenses. At Avantier, we offer lenses crafted from various substrates, including Schott, Ohara, and CDGM optical glass, as well as Corning 7980 fused silica, UV fused silica, infrared fused silica, calcium fluoride (CaF2), Barium fluoride (BaF2), Germanium, Zinc Selenide, and Zinc Sulfide. Each material possesses unique characteristics such as hardness, scratch resistance, and transmission range.

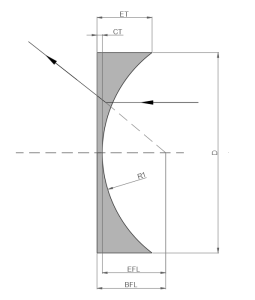

Diameter tolerance refers to the acceptable range of diameter values for a plano-concave lens, which determines its fitting into mounts or holders. Our factory standard adheres to a diameter tolerance of ± 0.05mm, ensuring precise compatibility. Moreover, we strive to achieve a manufacturing limit of ± 0.01mm, demonstrating our commitment to meticulous craftsmanship.

Thickness tolerance, another critical specification, defines the allowable variation in the center thickness of the lens. This variation directly impacts the optical path traversed by light passing through the lens. Avantier maintains a factory standard of ± 0.05mm for thickness tolerance, ensuring optimal performance. For even greater precision, we aim to achieve a manufacturing limit of ± 0.01mm.

The clear aperture, which represents the diameter of the lens portion that meets specifications, plays a vital role in optimizing performance. While the outer rim of a lens may be subject to manufacturing constraints, our factory standard guarantees a clear aperture exceeding 95 percent of the central dimension, ensuring maximum clarity and efficiency.

Centration, the measurement of decenter in a lens, refers to the displacement of the lens’s mechanical axis from its optical axis. The optical axis is defined by the line connecting the centers of curvature for the lens surfaces. Avantier adheres to a factory standard of less than 3 arc minutes for centration, providing lenses with excellent alignment. Our manufacturing limit pushes this precision further, maintaining centration within 1 arc minute.

Surface quality is a crucial factor, particularly for laser applications where high energy absorption can damage the optic. It pertains to the presence or absence of cosmetic defects such as scratches, pits, and digs. The surface quality is specified using a two-part scratch dig number, with lower values indicating higher quality. While the industry standard is typically 80-50, our factory standard for plano-concave lenses is an impressive 40-20 (after coating). We also offer the option of extremely high-quality 10-5 plano-concave lenses, albeit at a premium cost.

Surface irregularity refers to the deviation of a lens’s surface shape from the reference surface. Our factory standard ensures surface irregularity of less than ¼ lambda deviation, guaranteeing excellent optical performance. We aim to maintain a manufacturing limit of less than 1/10 lambda, emphasizing our commitment to delivering lenses of exceptional precision.

In conclusion, Avantier is dedicated to manufacturing top-quality plano-concave lenses for laser applications and beyond. With a wide selection of materials, stringent manufacturing standards, and the capability to create custom lenses, we are committed to meeting the diverse needs of our customers. Our lenses’ outstanding performance, combined with anti-reflection coatings and superior surface quality, makes them indispensable for reducing spherical aberration and achieving optimal results in various optical systems.

Please contact us if you’d like to schedule a consultation or request for quote on your next project.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.