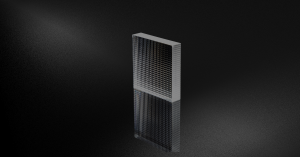

Avantier Microlens Arrays: Precision in Every Lens

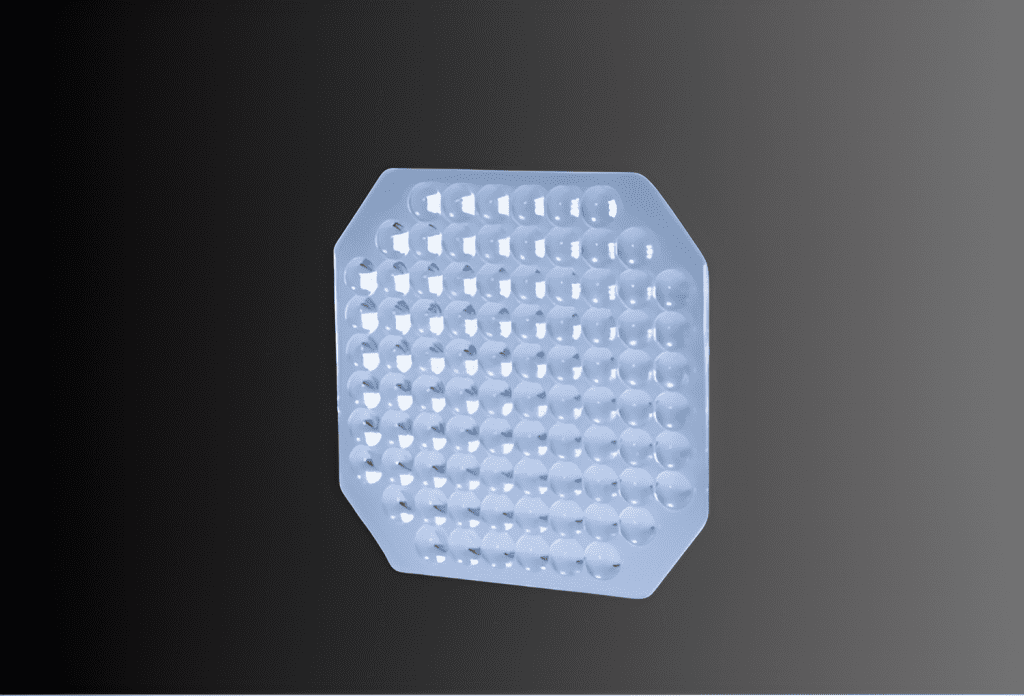

Avantier specializes in the design and manufacturing of high-performance microlens arrays (MLAs)—compact optical components engineered to deliver precise beam shaping, uniform illumination, and exceptional efficiency.

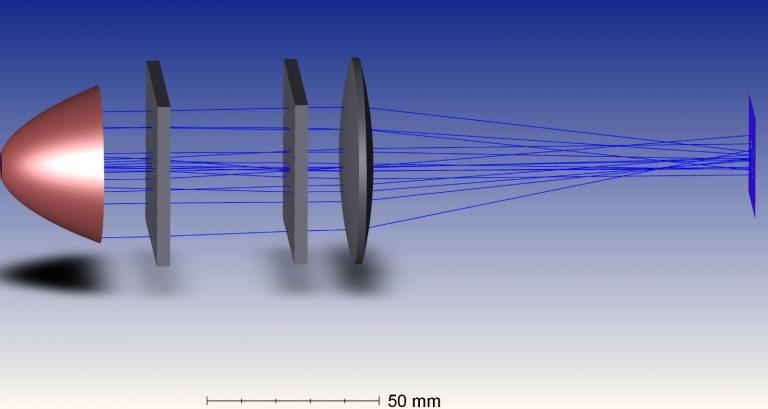

Microlens arrays, also known as microstructure lens arrays, consist of 1D or 2D grids of miniature lenses that collectively manipulate and homogenize light. They are indispensable in LiDAR, biomedical imaging, AR/VR systems, projection displays, and laser beam shaping, where reliability and accuracy are mission-critical.

Specifications

Diameter | +0, -0.1mm |

Surface accuracy | λ/2 @633nm or better |

Thickness | ±0.2mm |

Centration | ±0.04mm |

Surface quality | 20-10 |

Bevel | 0.2mm typical |

Material | SK2, BK7, UV-grade fused silica, and more |

Lens Pitch & Focal Length | Fully customizable |

Why Choose Avantier Microlens Arrays?

Custom Design Capabilities

- Tailored pitch, curvature, focal length, and fill factor

- Optimized for UV, visible, and near-infrared wavelengths

- Configurations available in spherical, aspherical, cylindrical, or hybrid designs

Advanced Manufacturing

- Semiconductor lithography, laser micromachining, and precision glass molding

- Tight tolerances for surface accuracy, thickness, and centering

- Optional AR coatings for maximum transmission

Premium Materials

- UV-grade fused silica, BK7, SK2, and other optical-grade glasses

- Superior durability for industrial, aerospace, and medical applications

End-to-End Partnership

- Support from prototyping to large-scale production

- Seamless integration into optical systems with engineering team guidance

- Trusted by global leaders in biomedical optics, automotive LiDAR, aerospace, AR/VR, and defense

Applications of Avantier Microlens Arrays

- LiDAR & Autonomous Vehicles: Beam steering and uniform illumination for mapping and navigation

- Biomedical Imaging: Miniaturized MLAs for endoscopes, microscopes, and diagnostic tools

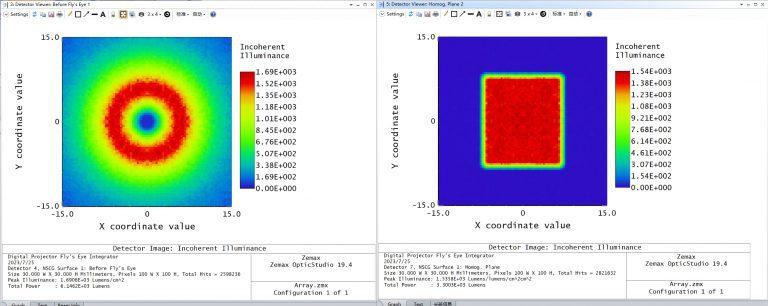

- AR/VR & Projection Displays: Uniform beams, glare reduction, and enhanced immersion

- Laser Systems: High efficiency beam homogenization and shaping

- Aerospace & Defense: Rugged MLAs for mission-critical sensing and imaging

- Wavefront Sensing & Astronomy: Shack–Hartmann arrays for adaptive optics and testing

Technical Advantages

- Uniform Light Distribution: Eliminates hot spots and fluctuations

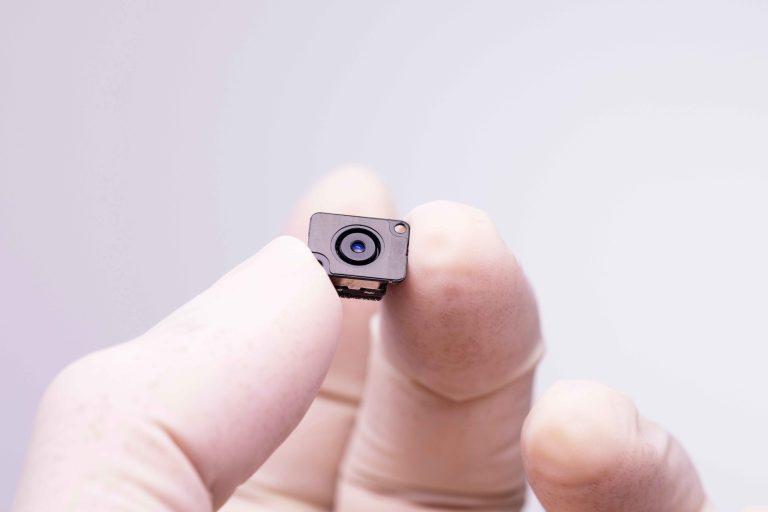

- Compact Footprint: Ideal for miniaturized optical modules

- High Transmission Efficiency: Reduced reflection and scattering losses

- Customization Flexibility: Designed to match exact system requirements

- Scalable Production: From prototypes to high-volume manufacturing

Technical Resource

What is a Microlens Array?

A microlens array is a miniature optical device composed of thousands to millions of tiny lenses on a substrate, arranged in 1D or 2D grids. Each microlens functions independently yet contributes to collective light regulation, enabling beam homogenization, focusing, and advanced optical manipulation.

Lens Arrangements

- Rectangular Grid: Ideal for alignment with pixel arrays

- Hexagonal Close-Pack: Maximizes fill factor for circular lenses

- Radial Gradient: Reduces edge distortion, enables annular beams

- Randomized: Suppresses speckle noise in holography and laser displays

Classification

- By Optical Principle: Refractive, diffractive, or hybrid

- By Material: Glass (durable, UV–IR range), polymers (cost-effective), semiconductors (photoelectric integration)

- By Functional Form: Spherical (focusing), cylindrical (fly’s eye condensers), aspheric (aberration correction)

Manufacturing Methods

- Photolithography (cost-efficient mass production)

- Femtosecond laser direct writing (high flexibility, free-form designs)

- Nano-imprint lithography (complex surfaces, scalable)

- Micro injection molding (polymer arrays)

- 3D printing (free-form, early-stage applications)

Innovative Applications

- Autonomous Driving: LIDAR beam control, IR/visible multispectral imaging, head-up display enhancement

- Imaging Technology: Smartphone cameras, 3D face recognition, medical endoscopy

- Laser Processing: Solar cell etching, EUV chip lithography, precision display cutting

- Biomedical Devices: Lab-on-a-chip diagnostics, gene detection, neuroimaging implants

- Display & Lighting: Adaptive headlights, glare-free projection, surgical shadowless lighting

FAQ: Microlens Arrays

Q: Are Avantier’s microlens arrays customizable?

Yes. Every MLA is engineered to your system requirements—pitch, focal length, materials, coatings, and even array geometry.

Q: Which industries benefit most from MLAs?

We support biomedical, automotive (LiDAR), AR/VR, aerospace, defense, and laser research markets worldwide.

Q: Do you offer prototyping before full production?

Yes. We partner with clients through the entire process, from concept validation to volume manufacturing.

Partner with Avantier for Microlens Arrays

Avantier’s microlens arrays deliver world-class optical performance, tailored to the unique challenges of your application. Whether you require beam homogenization, precise light shaping, or compact imaging solutions, our engineering and production expertise ensures results that exceed expectations.

📩 Contact Avantier today to discuss your custom microlens array requirements and discover how we can accelerate your optical innovations.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.